Overmolding and insert molding are two molding processes that share similarities but also have key differences.

Overmolding involves molding a part from one material and then molding another material over the first molded part. That’s why it’s sometimes referred to as multi-material molding, or, when using injection molding, two-shot molding.

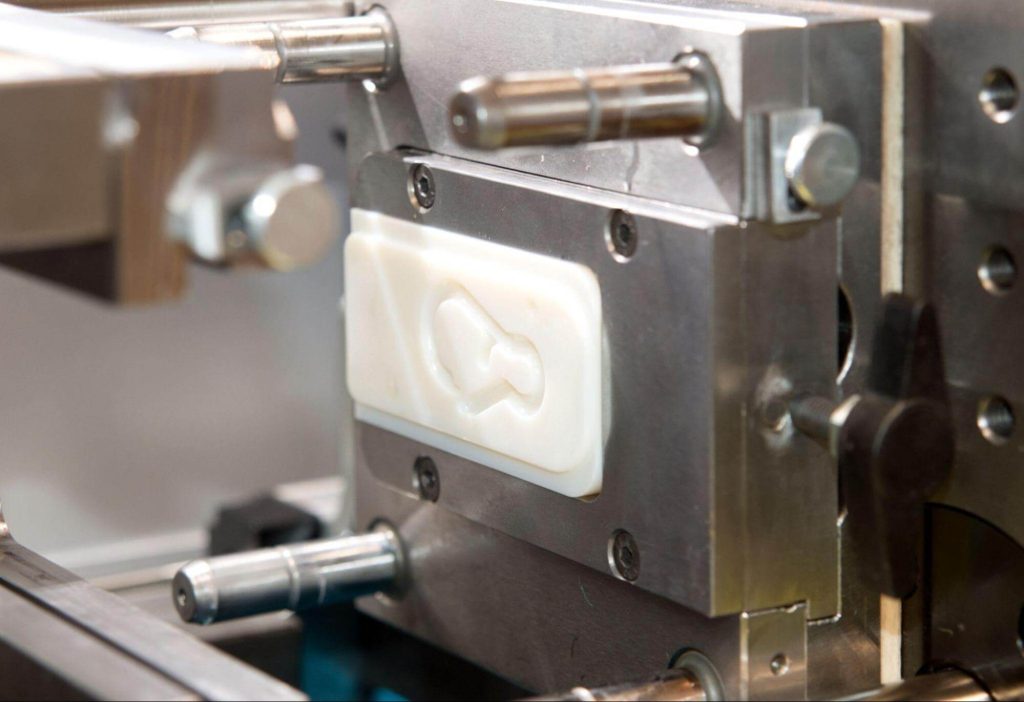

Insert molding begins when a pre-fabricated, pre-formed, or pre-shaped part is placed into a mold, and then a different material is molded around it. Sometimes, the inserts are made of metal. However, non-metallic inserts can also be used.

Both overmolding and insert molding allow parts to be seamlessly bonded together. Whether to improve comfort, provide a seal, enhance safety, or reduce noise and vibration, these two processes are used in a range of applications. But which process do you need? How do they compare?

Similarities Between Overmolding and Insert Molding

Overmolding and insert molding:

- Support the use of plastics and rubbers, including thermoplastic elastomers (TPE)

- Join multiple materials without the need for adhesives or fasteners

- Utilize the individual properties of the constituent materials

- Support the use of injection molding or compression molding

- Follow the design rules of injection or compression molding

- Have some of their own special design considerations

Sometimes, overmolding and insert molding can be used for the same application. For example, a plastic toothbrush can have a hard plastic handle and a softer silicone grip. Both parts are molded, but not necessarily in the same tool, on the same machine, or in a continuous cycle.

Differences Between Overmolding and Insert Molding

The differences between overmolding and insert molding are:

- Only overmolding allows for the continuous molding of two different parts (i.e., same tool, same machine, same cycle)

- Overmolding tools are more complex and therefore more expensive

- Only insert molding supports the use of metal components

- For small batches, insert molding is usually more cost-effective

Insert molding can support some applications that overmolding cannot. For example, screwdrivers typically have a metal blade and a plastic handle. The plastic handle can be molded, but the metal blade cannot. Therefore, insert molding is required.

How Overmolded Parts Are Manufactured

Overmolding always starts with molding the first part, sometimes called the substrate. The rest of the process varies depending on whether compression molding or injection molding is used.

Compression Molding Overmolding

Compression molding overmolding begins when an operator places pre-measured plastic or rubber material into a mold. The operator then closes the mold, which is usually preheated. Heat and pressure from the compression molding machine cause the material to flow and fill the mold. The part cools, the mold opens, and the part is removed by hand or ejected with pins.

Next, the molded part is placed into a different mold. Technically, this makes compression-molded overmolding more like insert molding. The operator then adds pre-measured plastic or rubber material and closes the compression mold. Heat and pressure are applied, and the second material covers part or all of the previously molded part, depending on the mold’s features.

Compression molds are less expensive than injection molds, but remember that compression molding overmolding requires two different tools. The first mold produces the first part, and the second mold is where the overmolding occurs. Processes that require multiple tools are more costly, but compression molding overmolding may still be cheaper than injection molding.

Injection Molding Overmolding

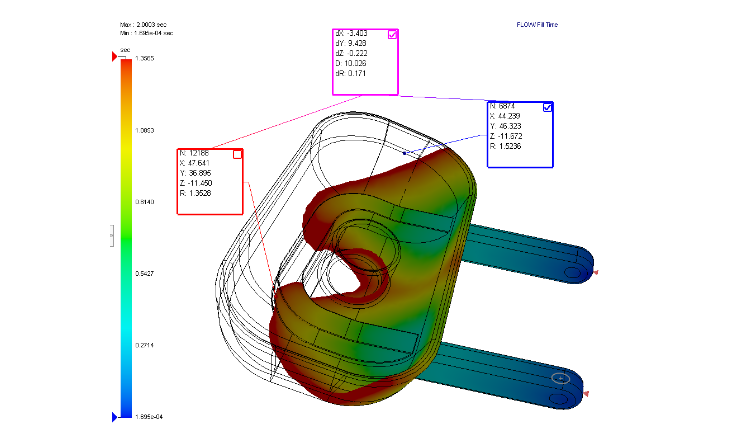

Injection molding uses an injection machine equipped with two barrels that can mix two different materials, such as a harder plastic and a softer silicone. After the first material is mixed and heated, it is injected into the mold. The part then cools but is not ejected from the tool. Instead, a second injection with the second material is made into the mold.

The second material overmolds part or all of the first part. Once the second material cools and solidifies, the mold opens and the overmolded part is ejected. The entire process uses a single mold, but this type of tool is more expensive because it is more complex. That’s why injection molding is typically used for higher production volumes.

How Insert-Molded Parts Are Manufactured

Insert molding always starts with placing an existing part into a mold. Whether the insert is pre-fabricated, pre-formed, or pre-shaped, the part must be positioned correctly inside the mold. Then, the rest of the process varies depending on whether compression molding or injection molding is used.

Insert Molding Using Compression Molding

Compression molding insert molding begins when an operator places the insert into a compression mold. This pre-fabricated or pre-formed part is often made of metal, such as threaded fasteners, blades, or pins for electrical connections. Alternatively, inserts can be made of non-metallic materials, such as rubber or plastic. Other types of materials (e.g., ceramics) can also be used, but metal, rubber, or plastic are the most common.

Next, the operator adds pre-measured plastic or rubber material to the mold, which already contains the insert. When heat and pressure are applied, the material flows and covers part or all of the insert, depending on the mold’s features. The material cools, the mold opens, and the insert-molded part is ejected manually or automatically.

Insert Molding Using Injection Molding

Injection molding insert molding begins when a pre-fabricated, pre-formed, or pre-shaped insert is placed inside an injection mold. The injection mold is then closed, and plastic or rubber material is heated and injected to fill the tool. The material cools, the mold opens, and the overmolded part is automatically ejected.

Because injection molding can be used to produce large quantities of parts, robots are sometimes used to pick and place inserts. However, injection molding can still use an operator to physically place the inserts inside the mold. Typically, this manual method is used for small-batch injection molding or when robots or other forms of automation are unavailable.

How to Design Parts for Overmolding or Insert Molding

Overmolding and insert molding are sub-processes of compression molding and injection molding. This means that if you’re designing a part that will undergo compression molding or injection molding, you need to follow the design guidelines for that process.

Parts that are overmolded or insert-molded also have some additional design guidelines.

Overmolding Design Guidelines

Follow these additional guidelines when designing overmolded parts.

- Make the overmold thickness less than or equal to the thickness of the substrate part.

- Avoid making the overmold so thick that it may shrink away from the substrate part during cooling.

- Choose an overmold material with a melt temperature that does not exceed the melt temperature of the substrate part.

Silicone overmolding presents special considerations because it is difficult to bond silicone elastomers to non-silicone polymers. Overmolding liquid silicone rubber (LSR) of one hardness and color to liquid silicone rubber (LSR) of a different hardness and color is also challenging. For difficult-to-bond materials, part designers can add recessed features called undercuts to promote adhesion.

Typically, designers seek to avoid undercuts unless absolutely necessary. This is because these part features complicate ejection and require the use of manual loading, lifters, or slides. Additional ejection mechanisms increase the cost of the mold, but remember that the mold is overmolded onto the first part rather than being ejected. Unless the overmold contains external undercuts, ejector pins alone or manual removal may be sufficient.

Insert Molding Design Guidelines

Follow these additional guidelines when designing insert-molded parts.

- Avoid using blades with sharp corners and use knurled parts when possible.

- Use inserts that are smaller than the molded part they are planned to be embedded in.

- For metal inserts, consider that off-the-shelf components (such as standard fasteners) are less expensive than custom parts that require design time and CNC machining.

If the molded part is made of silicone, remember that it is difficult to bond silicone elastomers to non-silicone materials. With insert molding, the insert itself helps determine the best method to promote adhesion. For example, smooth metal inserts require surface roughening and may need a specialized adhesive. Metal inserts with textured surfaces may not require roughening, but a specialized adhesive can help.

Inserts made of plastic or rubber (including silicone) require special attention. Low surface energy (LSE) plastics may require plasma, corona, or flame treatment to promote adhesion. Applying a textured surface to the molded part also helps. Since part texture is applied during injection molding or compression molding, producing plastic or rubber inserts requires the use of textured molds, which increases mold costs.

How Overmolded and Insert-Molded Parts Are Used

Overmolded and insert-molded parts are used in some of the same applications but also in different ones.

Examples of Overmolded Parts

In addition to toothbrushes, overmolded parts include children’s toys and baby care products. In these examples, a softer polymer that provides comfort and cushioning is molded over a harder polymer that provides strength and rigidity. With silicone overmolding, designers can take advantage of this elastomer’s thermal stability, wide temperature resistance, and biocompatibility. TPEs are also used in overmolded parts because they combine rubber-like elasticity with recyclability.

Examples of Insert-Molded Parts

Insert molding is not just used to produce hand tools like screwdrivers. Plastic is less expensive than metal and lighter in weight, but metal inserts provide the wear resistance needed for pulleys, knobs, and handles. Insert molding is also used to produce automotive sensors, electrical connectors, and bearings. Metal provides the conductivity for sensors and connectors, while plastic housings provide electrical insulation and protection from environmental contaminants.

Overmolding vs. Insert Molding Is Not a Competition

It’s easy to view overmolding vs. insert molding as a competition between two molding methods, but the real goal is to help you choose the right technology to design a successful product. Debaolong Seiko offers both insert molding and overmolding services, and we can help you determine whether compression molding or injection molding is the best choice for your application.

For more information, contact us at Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.