Both injection molding and blow molding can produce plastic parts. However, there are some important differences between these two manufacturing processes.

Injection molding heats plastic, injects it into a high-pressure mold, and produces solid plastic parts. Depending on their design, injection-molded parts can have complex shapes and intricate details. Examples include medical and aerospace components.

Blow molding uses pressurized air to inflate a tube of heated plastic inside a mold. Blow-molded parts are hollow and lightweight with relatively simple designs. Examples include water bottles and milk jugs.

Walls of such blow-molded parts are thinner than those of injection-molded parts.

There are other differences between blow molding and injection molding, as shown in the table below. Importantly, these differences cover everything from part design and material selection to tooling and production.

Table 1. Comparison of Injection Molding and Blow Molding

| Aspect | Blow Molding | Injection Molding |

|---|---|---|

| Part Design | ||

| Part Type | Hollow, simple parts | Solid, complex parts |

| Wall Thickness | Thin | Thick |

| Design Complexity | Less | More |

| Design Flexibility | Less | More |

| Strength | Less | More |

| Part Size | Small to medium | Small, medium, and large |

| Precision | Less | More |

| Materials | ||

| Forms | Powder, pellets | Powder, pellets |

| Thermoplastics | Fewer thermoplastics | More thermoplastics |

| Tooling | ||

| Cost | Lower | Higher |

| Lifespan | Shorter | Longer |

| Production | ||

| Pressure | Lower | Higher |

| Speed | Slower | Faster |

| Part Volume | Lower | Higher |

| Post-Processing Needed | Yes | No |

This article from Debaolong Seiko explains what part designers need to know when comparing blow molding and injection molding. Read on to understand how each manufacturing process works, then compare these two plastic manufacturing methods in detail.

How Does Blow Molding Work?

Blow molding uses heat, compressed air, and metal tools to produce plastic parts. There are three different versions of the blow molding process, depending on whether the plastic is extruded, injected, or stretched. There are other differences, as described in the following sections.

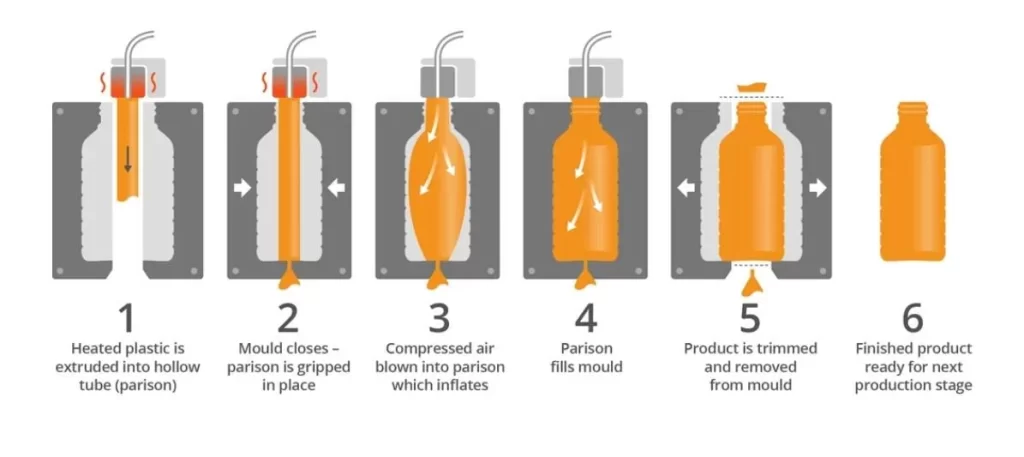

Extrusion Blow Molding (EBM)

Extrusion blow molding (EBM) heats plastic powder or pellets and extrudes this molten material into a hollow tube called a parison or preform. The mold then closes around the parison and holds the plastic tube in place. Compressed air is blown in, causing the parison to expand and the plastic to fill the entire mold. The part is cooled, removed from the tool, and trimmed.

Typically, EBM is used to mold parts and products such as kettles and bottles.

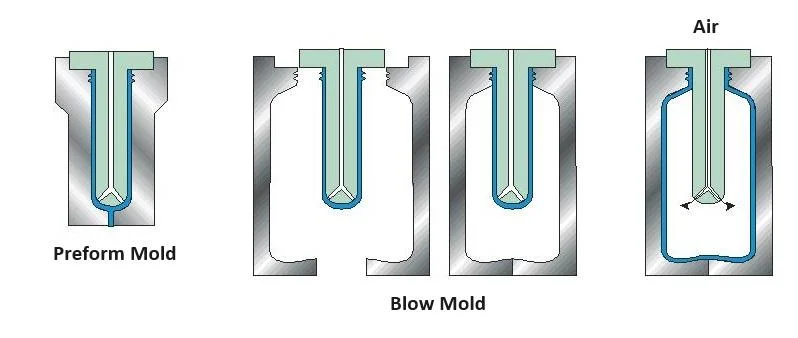

Injection Blow Molding (IBM)

Injection blow molding (IBM) heats plastic powder or pellets and injects this molten material into a special preform mold. The solid preform is then heated to a stretchable temperature and transferred to a blow mold, where the tool closes and air is blown in. The flexible plastic expands into the shape of the blow mold, then cools and solidifies. The mold opens, the finished part is ejected, and post-processing such as trimming is performed.

IBM is used to produce small, precision parts such as medical syringes and small bottles.

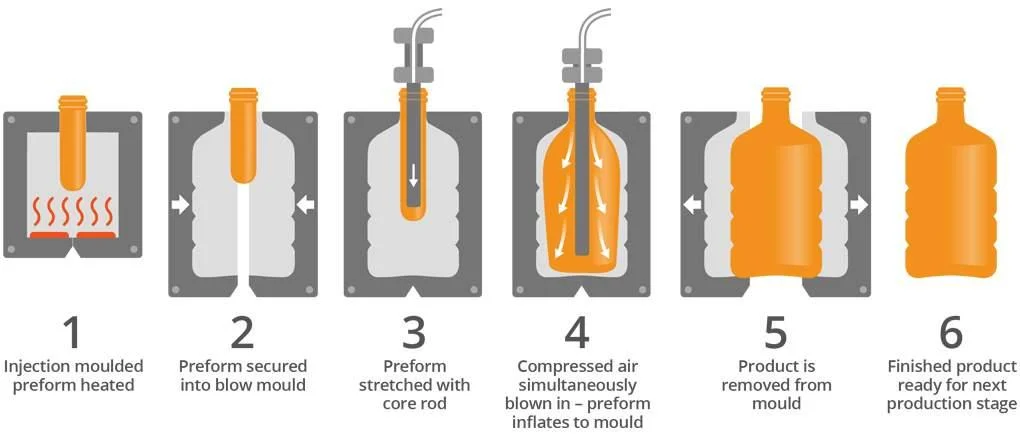

Stretch Blow Molding (SBM)

Stretch blow molding (SBM) stretches the preform or parison to improve the strength and transparency of the final product. This can be a one-stage or two-stage process.

- One-stage: The preform is molded and stretched on a single machine.

- Two-stage: The preform is molded, then reheated, and then blow-molded.

SBM is ideal for manufacturing strong, transparent containers such as plastic water bottles.

How Does Injection Molding Work?

Injection molding uses heat, pressure, and metal tools to produce plastic parts. The process begins when plastic powder or pellets are fed into a hopper. These pellets enter a barrel and are heated to a molten state. A screw inside the barrel pushes the molten plastic through gates and runners into the mold cavity. The plastic part is then cooled and ejected from the mold. Sometimes, post-processing is necessary.

Injection-molded parts moving on a conveyor belt after leaving the press

Now that you understand the basics of how blow molding and injection molding work, it’s time to consider their comparisons in terms of part design, materials, tooling, production, and applications.

Part Design

Injection molding supports the design of solid plastic parts with excellent surface finishes. Compared to blow molding, injection molding also supports higher design complexity and parts with features such as thicker walls and ribs to increase strength. Additionally, injection-molded parts are characterized by higher precision, tighter tolerances, and greater part-to-part uniformity. In terms of size, injection molding supports small, medium, and large parts.

Blow molding supports the design of hollow, lightweight plastic parts with thinner walls. Compared to injection molding, this process also supports simpler designs that require lower precision. Blow-molded parts are weaker than injection-molded parts and may have defects such as air leaks, streaks, and thin walls. Blow molding does not support large parts but is suitable for small to medium parts.

Materials

Both blow molding and injection molding support the use of thermoplastics, which are polymers that can be recycled and reused. Typically, blow molding uses soft, flexible thermoplastics such as acrylonitrile butadiene styrene (ABS), high-density and low-density polyethylene (HDPE and LDPE, respectively), and polypropylene (PP). These materials are ideal for manufacturing hollow, thin-walled products such as bottles and containers.

Injection molding can use these materials as well as rigid plastics such as polycarbonate (PC). Additionally, injection molding can be used with reinforced materials, such as glass-filled nylon. Blow molding can also use these materials, but applications are less common because blow-molded products are not as strong as injection-molded parts.

Other thermoplastics used in both processes include:

- Acrylic

- Acetal (POM)

- Polyether ether ketone (PEEK)

- Polyvinyl chloride (PVC)

- Polyester

- Polyurethane

Because blow molding produces hollow, thin-walled parts, it uses less material compared to injection molding. This reduces material costs, but blow molding has other advantages. For example, because blow-molded parts are lighter, transportation costs are lower. However, thin-walled parts are also more susceptible to damage.

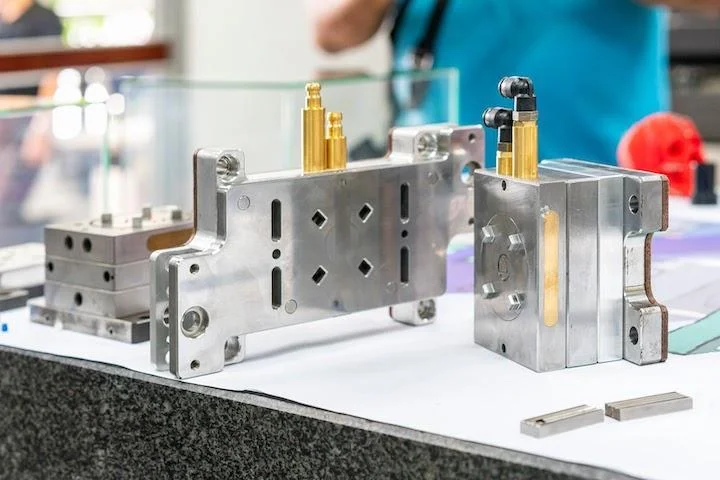

Injection molds cost more than blow molds but have a longer lifespan.

Tooling

Blow molds are less expensive. Due to their lower molding pressure, blow molds use tools made of less durable and cheaper materials, usually aluminum, stainless steel, or beryllium copper alloys. Blow molds do not have as many cycles as injection molds, but blow molding is a low-to-medium volume process. Blow molds are also less costly because part designs are less complex and require less machining.

Injection molds are more expensive because they are made of materials capable of withstanding high clamping pressures. Otherwise, the two halves of the mold might separate during injection. While injection molds can be made of aluminum, various grades of steel are used to produce parts that require higher precision and higher output. The larger part sizes and higher complexity supported by injection molding also increase mold costs. However, as part volume increases, the per-part cost of injection molds decreases.

Production

In terms of part production, blow molding and injection molding differ in pressure, speed, part volume, and whether post-processing is needed. Injection pressure is higher, but this plastic manufacturing process is faster, capable of producing parts in as little as 60 seconds. This makes injection molding ideal for high-volume production, despite its higher initial mold cost.

Blow molding is slower with longer cycle times. Nevertheless, this may not be an issue for low-to-medium part volumes, especially considering the lower initial mold cost of blow molding. However, because blow-molded parts are less precise, trimming is required. This adds cost and extends project timelines. Extrusion blow molding is faster than injection blow molding, and stretch blow molding can be faster or slower depending on whether a one-stage or two-stage process is used.

Applications

Finally, blow molding and injection molding differ in their applications.

Blow-molded parts are used in the following types of applications:

- Packaging: Plastic bottles, containers, and jugs for products such as food and beverages

- Automotive: Fuel tanks, pipes, and reservoirs

- Household items: Laundry baskets, water containers, and toys

- Medical: Vials and pharmaceutical packaging

- Industrial: Tanks for storing chemicals

- Furniture and home goods: Trash cans and patio chairs

Injection-molded parts are used in the following types of applications:

- Packaging: Caps, lids, and thick-walled containers

- Automotive: Bumpers, dashboards, door panels, and interior components

- Consumer goods: Toys, household items, and electronic enclosures

- Medical: Syringes, diagnostic equipment, and disposable healthcare products

- Electronics: Enclosures and components for electronic devices

- Construction: Flooring, roof vents, insulators, and deck fasteners

Is Blow Molding or Injection Molding the Right Choice?

What kind of plastic parts does your project require? Solid or hollow? Thin-walled or thick-walled? Simple or complex? Blow molding is suitable for parts such as water tanks, containers, beakers, and bottles; however, if your part design has complex features and requires fine details, injection molding is a better choice.

Debaolong Seiko offers plastic injection molding services and provides expert design for manufacturing (DFM) feedback along with your quote request. As your preferred platform for mechanical parts from prototyping to production, Debaolong Seiko can injection mold complex parts at an impressive speed. Are you ready to get started?