Both injection molding and blow molding produce plastic parts, but they differ significantly in process, capabilities, and applications.

Injection molding heats plastic, injects it into a high-pressure mold, and produces solid parts with complex shapes and intricate details—ideal for medical and aerospace components. Blow molding, by contrast, uses pressurized air to inflate a heated plastic tube within a mold, creating hollow, lightweight parts with simpler designs (e.g., water bottles, milk jugs).

Blow molded parts typically have thinner walls than injection molded parts. Other differences span part design, material selection, tooling, and production, as outlined in the table below.

Table 1: Injection Molding vs. Blow Molding Comparison

| Factor | Blow Molding | Injection Molding |

|---|---|---|

| Part Design | ||

| – Part Type | Hollow, simple parts | Solid, complex parts |

| – Wall Thickness | Thin | Thick |

| – Complexity | Low | High |

| – Flexibility | Limited | High |

| – Strength | Lower | Higher |

| – Size Range | Small to medium | Small, medium, and large |

| – Precision | Lower | Higher |

| Materials | ||

| – Forms Used | Powder, pellets | Powder, pellets |

| – Thermoplastics | Fewer options | More options |

| Tooling | ||

| – Cost | Lower | Higher |

| – Lifespan | Shorter | Longer |

| Production | ||

| – Pressure | Lower | Higher |

| – Speed | Slower | Faster |

| – Volume Suitability | Lower | Higher |

| – Post-Processing | Required (e.g., trimming) | Not required |

How Does Blow Molding Work?

Blow molding uses heat, compressed air, and metal tools to produce plastic parts. There are three main types, differing in how plastic is extruded, injected, or stretched:

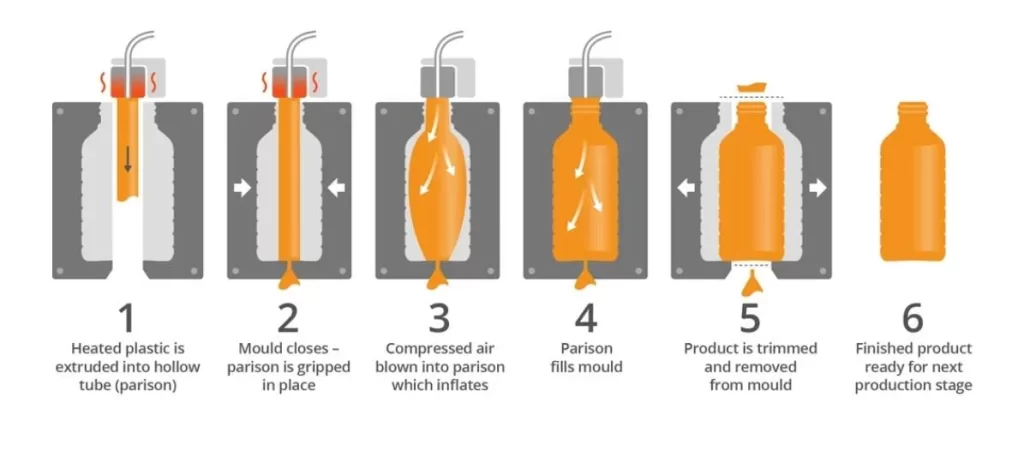

1. Extrusion Blow Molding (EBM)

EBM heats plastic powder or pellets, extruding the molten material into a hollow tube called a parison. A mold closes around the parison, securing it in place. Compressed air is blown into the parison, expanding it to fill the mold cavity. The part cools, is removed from the mold, and trimmed.

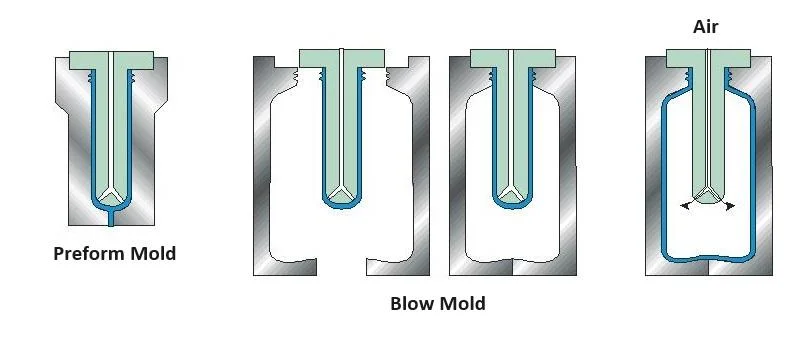

2. Injection Blow Molding (IBM)

IBM heats plastic powder or pellets and injects the molten material into a preform mold, creating a solid preform. The preform is reheated to a malleable temperature, transferred to a blow mold, and inflated with air. The plastic expands to match the mold shape, cools, and solidifies. The finished part is ejected and trimmed.

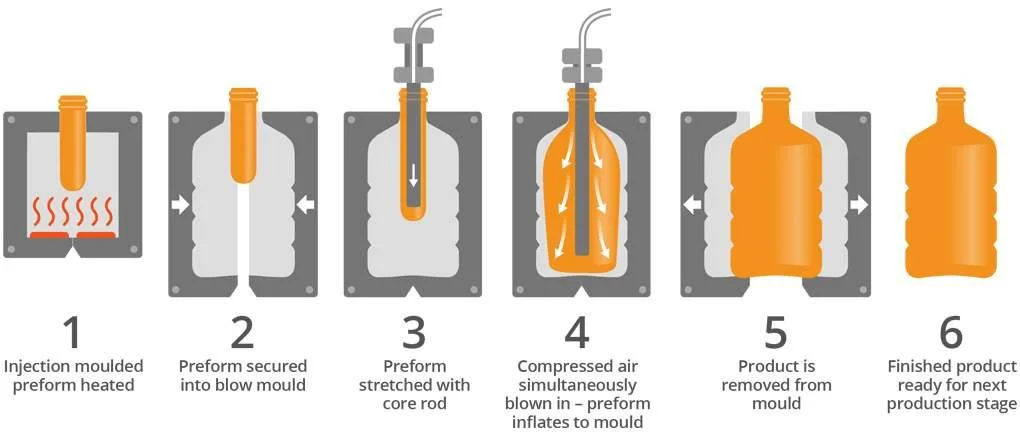

3. Stretch Blow Molding (SBM)

SBM stretches the preform or parison to enhance strength and clarity. It can be a one-stage process (preform molding and stretching in one machine) or two-stage (preforms are molded, reheated, and then stretched/blown).

How Does Injection Molding Work?

Injection molding uses heat, pressure, and metal tools to produce solid plastic parts. Plastic powder or pellets are fed into a hopper, heated to a molten state in a barrel, and injected by a screw through gates and runners into a mold cavity. The plastic cools, solidifies, and is ejected from the mold. Post-processing is rarely needed.

Part Design

- Injection Molding: Supports solid parts with complex geometries, thick walls, ribs (for strength), and fine details. It achieves tight tolerances and high part-to-part uniformity, suitable for small, medium, and large parts.

- Blow Molding: Produces hollow, lightweight parts with thin walls and simple designs. Precision is lower, and defects like uneven walls or air leaks are more common. It is limited to small to medium sizes.

Materials

Both processes use thermoplastics, but injection molding offers more flexibility:

- Blow Molding: Typically uses flexible thermoplastics like ABS, HDPE, and PP, optimized for thin-walled, hollow parts. It consumes less material, reducing costs and shipping weights, but parts are more prone to damage.

- Injection Molding: Works with rigid plastics (e.g., polycarbonate) and reinforced materials (e.g., glass-filled nylon). It supports a wider range of thermoplastics, including acrylic, PEEK, and PVC.

Tooling

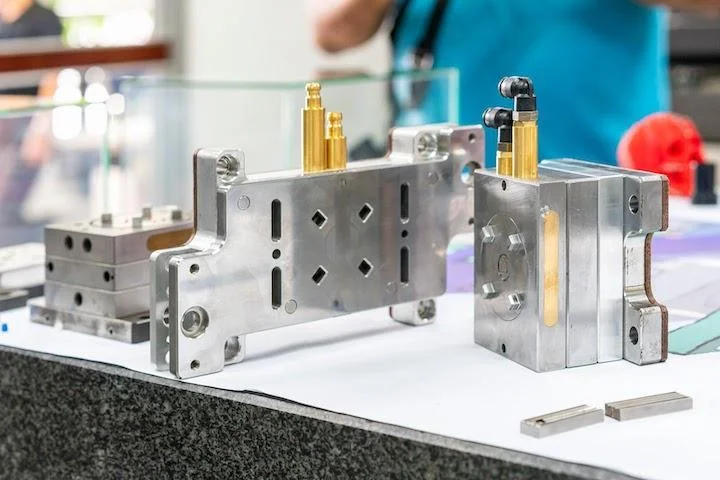

- Blow Molding: Molds are cheaper, made from less durable materials (aluminum, stainless steel) due to lower molding pressures. They have shorter lifespans and are cost-effective for low-to-medium volumes, as simpler part designs require less machining.

- Injection Molding: Molds are more expensive, crafted from steel (or aluminum for low volumes) to withstand high clamping pressures. Larger part sizes and greater complexity increase costs, but per-part costs decrease with higher volumes.

Production

- Speed & Volume: Injection molding is faster (cycle times as short as 60 seconds), making it ideal for high-volume production despite higher initial mold costs. Blow molding has longer cycle times, suitable for low-to-medium volumes.

- Post-Processing: Blow molded parts require trimming (adding cost and time), while injection molded parts are often ready-to-use. EBM is faster than IBM, and SBM speed varies by stage (one-stage vs. two-stage).

Applications

- Blow Molding:

- Packaging (bottles, food containers)

- Automotive (fuel tanks, ducts)

- Home goods (laundry baskets, toys)

- Medical (vials, drug packaging)

- Industrial (chemical storage tanks)

- Injection Molding:

- Packaging (caps, thick-walled containers)

- Automotive (bumpers, dashboards)

- Consumer goods (toys, electronics enclosures)

- Medical (syringes, diagnostic tools)

- Construction (floor tiles, insulators)

Choosing Between Blow Molding and Injection Molding

Consider your part’s needs: hollow/thin-walled vs. solid/thick-walled, simple vs. complex. Blow molding suits tanks, bottles, and containers; injection molding is better for parts with intricate features and tight tolerances.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.