Now that you’ve successfully CNC machined your parts, it’s time to give them the care they deserve. Don’t let these raw components go out into the world without a little extra polish. Your work isn’t done once the CNC machining of parts is complete. These raw components may have unsightly surface finishes, may not be strong enough, or are simply part of a multi-piece complex product. Either way, post-processing is necessary for a range of applications, and we’re here to guide you through some considerations so you can choose the right secondary operations for your project.

This article is part of a three-part series covering options and considerations for heat treatment processes, finishes, and hardware installation. Any or all of these may be necessary to take your parts from their machined state to customer-ready. Here, we discuss heat treatment, while parts two and three examine finishes and hardware installation.

Heat Treatment Before or After CNC Machining?

CNC machining of 17-4 PH stainless steel parts

Heat treatment is a processing option either before or after machining. Why use one method over the other? Both pre-CNC machining and post-CNC machining heat treatment processes are common, each with specific advantages and considerations. The order in which you choose to heat treat and machine the metal affects material properties, machining processes, and part tolerances.

Heat Treatment Before CNC Machining

Advantages

Opting for pre-heat-treated metal does have some benefits. With hardened metal, your parts can maintain tighter tolerances, and sourcing materials is easier since pre-heat-treated metals are readily available. Additionally, if you wait until after machining, heat treatment adds another time-consuming step in the production process.

Disadvantages

Using already heat-treated material can impact your machining (harder materials take longer to machine, and tooling wears faster, which increases machining costs). Depending on the type of heat treatment applied and the depth below the surface the material is affected, if you cut away the hardened layer of the material, you’ll defeat the purpose of using hardened metal in the first place. There’s also the possibility that the machining process can generate enough heat to increase the hardness of the workpiece. Certain materials, such as stainless steel, are more prone to work hardening during machining, so extra care is needed to prevent this.

Heat Treatment After CNC Machining

Advantages

On the other hand, heat treatment after machining gives you more control over the process. There are various types of heat treatments, and you can choose which one to use to achieve the desired material properties. Post-machining heat treatment also ensures consistent heat treatment effects across the entire part surface. For pre-heat-treated materials, the heat treatment may only affect the material to a certain depth, so machining might remove hardened material in some areas but not others.

Disadvantages

As mentioned, post-machining heat treatment adds cost and lead time due to the extra step of outsourcing the process. Heat treatment can also cause parts to warp or deform in other ways, affecting the tight tolerances achieved during machining. It’s harder to maintain tight tolerances due to the variability experienced during heat treatment. From first-hand experience, it’s difficult to precisely maintain temperatures in large ovens, which is something to consider when heat treating CNC machined parts.

Heat Treatment Processes

In general, heat treatment of metals involves exposing the metal to a specified temperature for a period of time to alter material properties such as strength, ductility, and toughness, or to relieve residual stresses built up in the material. Usually, this means increasing the metal’s strength and hardness to enable it to withstand more extreme applications. However, certain heat treatment processes, such as annealing, actually reduce the hardness of metals or soften them. Let’s take a look at different heat treatment method

Hardening

Hardening is used to—you guessed it—make metal harder. Higher hardness means the metal is less likely to dent or show marks when impacted. Hardening of metal actually improves its resistance to plastic deformation. Hardening also increases the metal’s tensile strength, which is the force at which the material fails and breaks. Greater strength makes the material more suitable for certain applications. Hardening is typically applied to ferrous metals (like steel), though other metals such as titanium or aluminum can undergo similar processes called nitriding.

What happens when metal is hardened?

During hardening, the workpiece is heated to a specific temperature above the metal’s critical temperature, or the point at which its crystal structure and physical properties change. The critical temperature is when the metal undergoes a phase transformation (e.g., when steel becomes austenite) or when solute-rich precipitates dissolve. The metal is held at this temperature and then cooled by quenching in water, brine, or oil.

The quenching process can form very fine solute-rich precipitates, which inevitably stabilize the metal’s crystal structure and leave less room for deformation at grain boundaries. This increases the metal’s hardness and yield strength. The quenching fluid depends on the metal’s specific alloy. Each quenching fluid has a unique cooling rate, so it’s chosen based on how quickly you need to cool the metal.

Surface Hardening

Surface hardening, or case hardening, is a type of hardening that only affects the outer surface of the material. This process is usually done after machining to form a durable outer layer.

Surface hardening processes are applied to steel alloys and work by diffusing carbon, nitrogen, or boron (called carburizing, nitriding, and boronizing, respectively) into the outer layer of the steel at high temperatures, followed by heat treatment to increase hardness. The depth of penetration of carbon, nitrogen, or boron depends on exposure time and temperature.

The outer layer of the part is typically surface-hardened to resist compression and impact, while the interior of the part can remain softened and ductile. This combination of a soft core and hard shell improves fatigue and high stress resistance, making it particularly useful for gears and bearings.

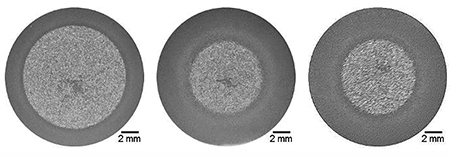

Hardening depth can vary with changes in process parameters

Precipitation Hardening

Precipitation hardening is a heat treatment process performed at low temperatures for specific metals with certain alloying elements. These elements include copper, aluminum, phosphorus, and titanium. Precipitation hardening has three stages:

- Solution annealing, i.e., treating the metal with a chemical solution below the metal’s eutectic temperature to allow precipitation of specific elements;

- Quenching, which allows solubility of the precipitating elements;

- Aging, where the part is heated and forms a two-phase base alloy. When heated for an extended period, these elements precipitate or form solid particles within the solid metal. This affects the grain structure, increasing the material’s strength and corrosion resistance (most commonly).

Annealing

Don’t roll your eyes, but annealing is like a wellness retreat for metal. Annealing is used to soften metal, as well as to relieve stress and increase the material’s ductility. This process makes the metal significantly more machinable. At the microstructure level, the metal is more refined, thus softened. You can anneal steel, copper, aluminum, and brass alloys.

How is the annealing process done?

To anneal metal, the metal is slowly heated to a specific temperature (above the material’s critical temperature), held at that temperature, and finally cooled at a slow, set rate. This slow cooling process is done by burying the metal in insulating material or keeping it in the furnace as the furnace and metal cool.

There are three metallurgical stages or phases in the annealing process:

- Recovery, which occurs during heating; removes crystal defects (primarily linear dislocations in the crystal structure); results in reduced internal stress within the metal;

- Recrystallization, which occurs during controlled cooling; leads to grain nucleation and growth to replace any deformed areas due to internal stress; promotes uniformity of grain structure and softening of the metal;

- Grain growth, which can occur if the annealing process is prolonged; leads to a coarse microstructure, which will limit ductility and may cause weakening of the metal;

From a thermodynamic perspective, annealing actually accelerates the spontaneous process of internal stress relief (by increasing heat to act as a catalyst), which technically is a reduction in the metal’s Gibbs free energy. Cooling actually promotes the elimination of lattice vacancies within the metal, reducing stress by forming a more uniform and stronger crystal structure.

Tempering

Tempering is a special process applied to hardened and quenched metals to relieve stress and soften them, similar to the annealing process. The tempering process essentially involves reheating already hardened metal. Tempering usually occurs at a lower temperature than hardening and causes phase transformations (i.e., bainite, martensite, and ferrite in steel alloys) through the precipitation of intermetallic particles, resulting in enhanced strength and ductility. Aging is a special type of tempering for aluminum alloys.

Precipitation-hardening alloys must undergo a solution process where the metal is heated to allow uniform distribution and dissolution of alloying elements, and quenched at a rapid rate to prevent these elements from dropping out of solution. These precipitation-hardening alloys are tempered at temperatures below the solution temperature. The mechanism is similar to how tempering works for steel, but the specific mechanism is the precipitation of intermetallic compounds, which increase the metal’s strength by preventing the formation of dislocations within the crystal structure. The amount and general size of these intermetallic precipitates are controlled by time and temperature during the tempering process.

Final Thoughts

Heat treatment of CNC machined parts is often necessary to achieve the physical properties required for a given application. While heat treating material before CNC machining can save overall production time, it increases the cost of the machining process. Meanwhile, heat treating parts after CNC machining makes the material easier to machine but adds an extra step to the production process.

Depending on your application, you must weigh the benefits of increased hardness and tighter tolerances against the drawbacks of longer machining times associated with pre-heat-treated materials. The good news is that Debaolong Seiko now offers hardening, surface hardening, and tempering as finishing options for selected CNC machined materials. Additionally, our experts can help you choose the right material for your next CNC project.

| Material | Debaolong Seiko Heat Treatment Processes Offered |

|---|---|

| A286 stainless steel | Quenching, surface quenching, tempering |

| 410 stainless steel | Quenching, surface quenching, tempering |

| 416 stainless steel | Quenching, surface quenching, tempering |

| 420 stainless steel | Quenching, surface quenching, tempering |

| 440C stainless steel | Quenching, surface quenching, tempering |

| 1018 low carbon steel | Quenching, surface quenching, tempering |

| A36 steel | Quenching, surface quenching, tempering |

| 1045 carbon steel | Quenching, surface quenching, tempering |

| 12L14 carbon steel | Quenching, surface quenching, tempering |

| 1215 carbon steel | Quenching, surface quenching, tempering |

| A514 alloy steel | Quenching, surface quenching, tempering |

| 4140 alloy steel | Quenching, surface quenching, tempering |

| 4340 alloy steel | Quenching, surface quenching, tempering |

| 4130 alloy steel | Quenching, surface quenching, tempering |

| 8620 steel | Quenching, surface quenching, tempering |

| Cast iron | Quenching, surface quenching, tempering |

| Titanium Grade 2 | Quenching, surface quenching, tempering |

| Titanium Grade 5 | Quenching, surface quenching, tempering |

| A2 tool steel | Quenching, surface quenching, tempering |

| D2 tool steel | Quenching, surface quenching, tempering |

| O1 tool steel | Quenching, surface quenching, tempering |

For more information, please contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.