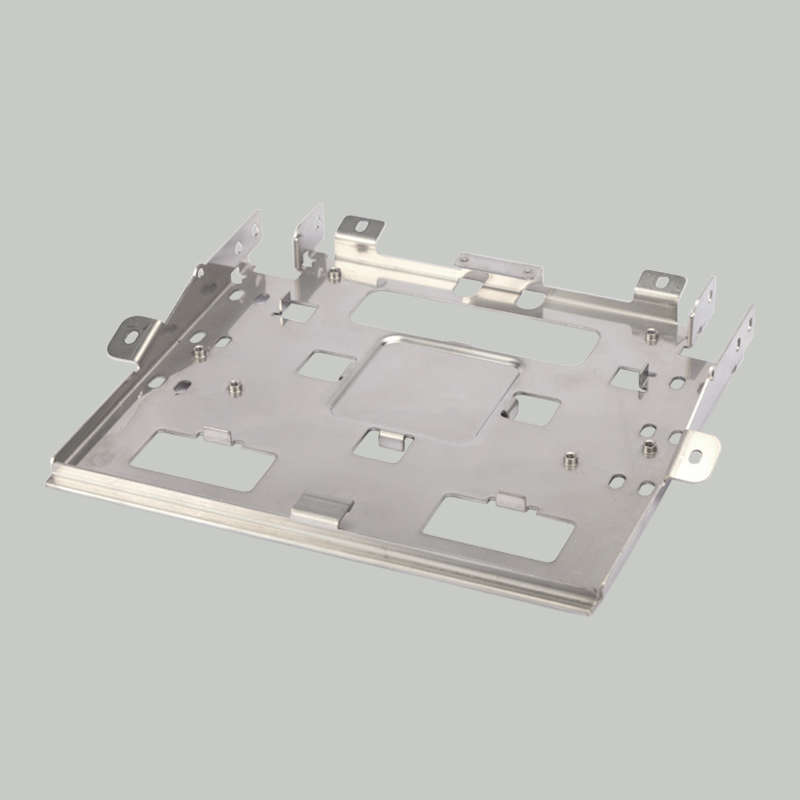

Sheet metal bending and forming: The bending and forming of metal sheets are performed on a bending machine. The sheet to be formed is placed on the bending machine, and the brake plates are lifted using lifting levers. The workpiece is then slid into the appropriate position, and the brake plates are lowered onto the sheet to be formed. The metal is bent and formed by applying force to the bending levers on the bending machine.

Process Cost: Standard die costs (none), per-piece costs (low to medium)

Typical Products: Consumer electronics, packaging, transportation, building hardware, etc.

Production Volume: Suitable for mass production (up to 5,000 pieces) and custom single-piece orders

Quality: High bending accuracy with an error of approximately 0.1 mm (0.004 in)

Speed: Capable of performing 6 bends per minute, though the initial setup of the bending machine may take a longer time.

Suitable materials

Suitable for almost all metal materials, with the most commonly used materials being steel, aluminum, copper, and titanium, which are highly ductile metal sheets.

Design Considerations

1. The maximum single-piece bending length can reach 16m (52ft)

2. The bending path of metal must be straight

3. For ductile materials, the inner radius of the bend is equal to the thickness of the sheet; for hard materials, the inner radius is three times the thickness of the sheet

4. If the metal sheet has not been heat-treated, the maximum bending thickness is 50 mm (2 in)

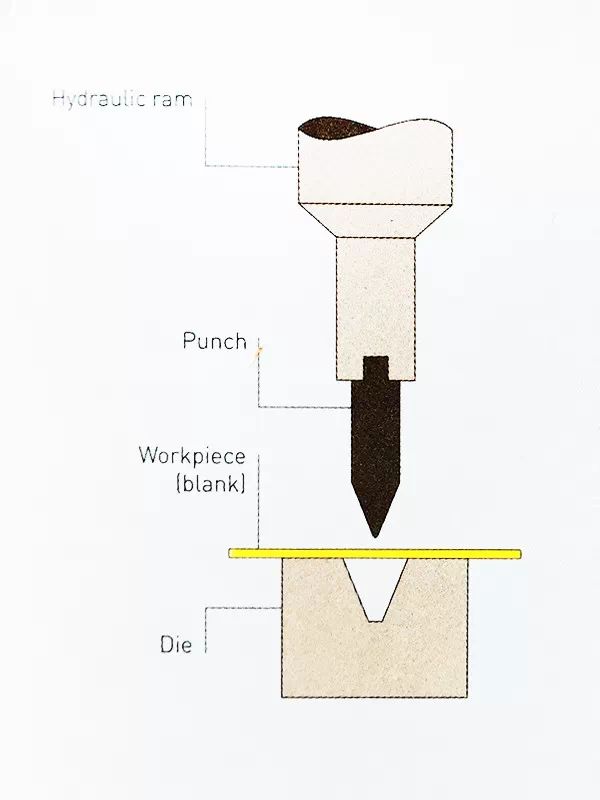

The punch is driven by a hydraulic cylinder (providing vertical pressure), and the pressure magnitude is determined by four factors: bending length, sheet thickness, ductility, and bending radius.

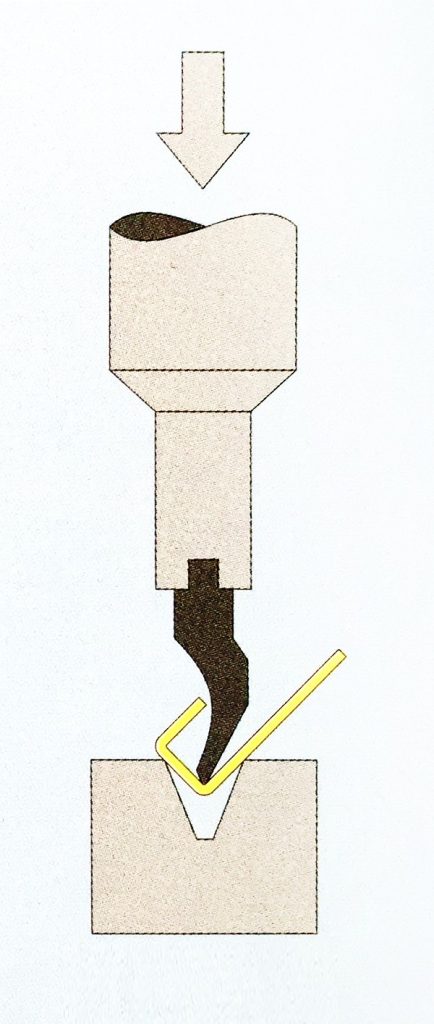

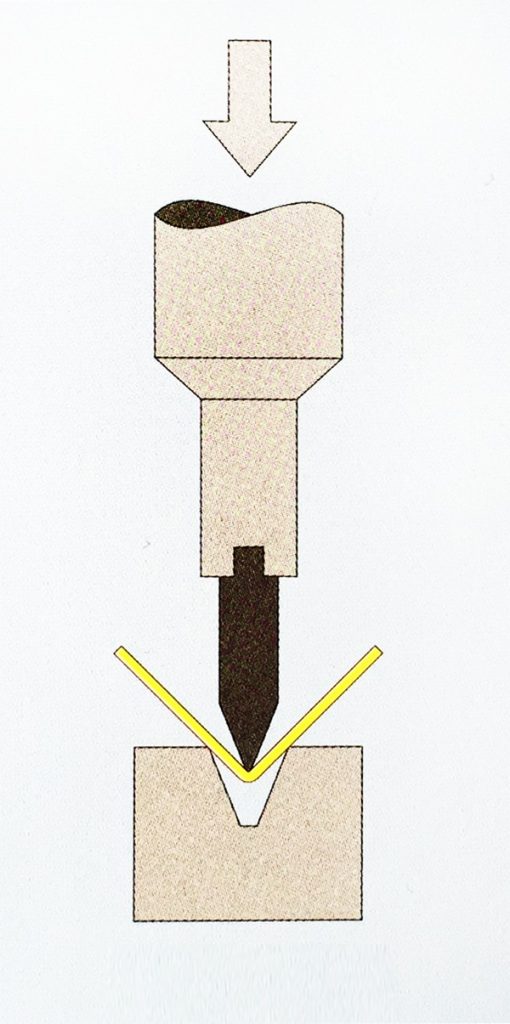

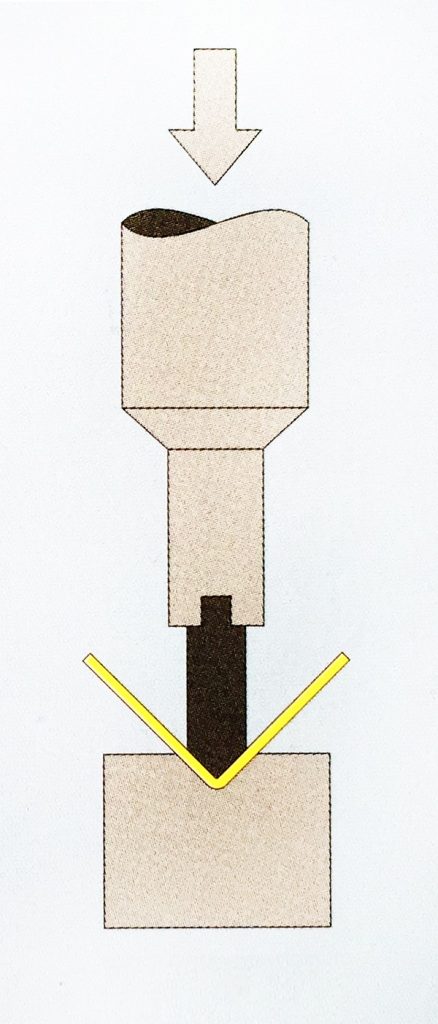

Step 2: The punch is driven by a hydraulic cylinder to press down on the sheet metal and bend it into shape. Each bend takes only a few seconds and is controlled entirely by a computer.

The shape of sheet metal bending is determined by the punch type and hard mold type, and is divided into standard molds and non-standard molds.

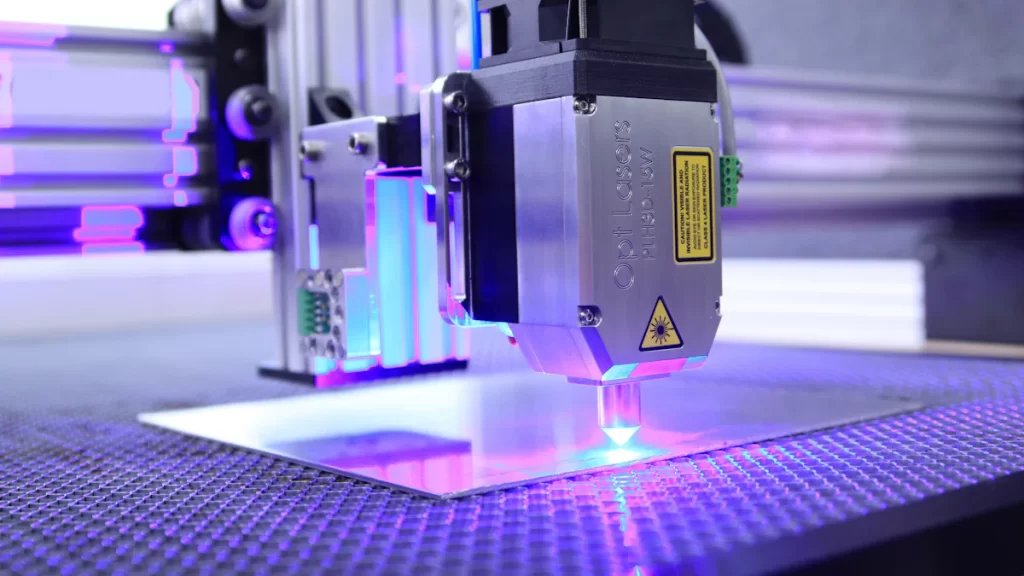

Sheet metal laser cutting and bending processes are one of the manufacturing steps at Debaolong Seiko, where we have over a decade of specialized experience in this field.