Metal parts are unique to every industry and application. Engineers and designers need to understand the materials, manufacturing processes, and application scenarios of parts to determine the appropriate method for production.

The manufacturing methods for metal parts can vary greatly. Each process has its own advantages, compatible materials, and trade-offs, and a deeper understanding of the range of production methods can further improve this decision-making process. The following is an overview of eight different manufacturing processes that can be used to create custom metal parts. They are:

- CNC milling and CNC turning

- Extrusion

- Metal casting

- Die casting

- Metal injection molding

- Forging

- Sheet metal and stamping

- Metal 3D printing

1. CNC Milling and CNC Turning

CNC machining technology primarily consists of two types. CNC milling machines are automated cutting machines that use a rotating spindle head to remove unwanted material. As the spindle rotates, the material is held against a fixed tool and rotates to remove the raw material into the desired shape. This technology is suitable for a variety of materials, including plastics, aluminum, stainless steel, and titanium.

How CNC Machining and Turning Work

CNC turning involves the use of CNC lathes or multi-axis CNC turning centers. Manufacturers use CNC lathes to turn cylindrical and concentric features on parts. Power lathes combine end mills and drills to produce off-axis features without changing the platform. By using specialized CNC lathes (commonly known as Swiss machines) to combine multiple tools and spindles within the machine, small parts with complex features can be produced quickly.

A typical lathe rotates the part around a central axis to remove material using rigid cutting tools. Other functions performed by lathes include creating internal and external threads, creating flange ring features, O-ring grooves, and knurled textures.

CNC lathes and CNC milling machines have different axis configurations. CNC lathes are typically 3-axis or 4-axis machines with a single spindle. 3-axis CNC machining involves processing material along the X, Y, and Z axes, removing chips in these three directions, while 4-axis tools combine the concentric features of a lathe with the tilting motion of a milling machine. Lathes are ideal for producing circular parts and are more suited for operations involving irregular shapes and sharp edges, while milling machines are the opposite.

More modern CNC technology supports up to five axes. These tools add tilting and rotating capabilities to the traditional X, Y, and Z axes, enabling precise cutting of more detailed parts. Five-axis machining is also more efficient, allowing more part features to be created in a single operation. Milling machines come in various configurations, with the most common being three-axis, four-axis, and five-axis.

CNC stands for Computer Numerical Control. Operators use G-code (a programming language that provides machine movement instructions) to control CNC milling machines and lathes. Modern programming instructions are created using Computer-Aided Manufacturing (CAM) software. This code instructs the machine to move the cutting tool to a specific position and control its speed and feed rate, including rotation, cutting depth, and workpiece movement. The complexity of G-code depends on the number of axes and the toolset used by the machine.

CNC Materials

CNC milling machines and CNC lathes are suitable for similar materials, including aluminum, brass, bronze, copper, steel, stainless steel, titanium, and zinc alloys. These tools can also be used for plastics and composite materials, such as acetal, ABS, G-10, and high-performance materials such as PEEK or PTFE.

CNC Use Cases and Applicable Industries

CNC milling machines are the workhorses of manufacturing, offering precision and repeatability, making them ideal for rapid prototyping and small- to large-scale production runs. Their broad material compatibility makes them suitable for almost any application.

CNC lathes are equally versatile. Production using lathes requires fewer hands-off setup times, making them an effective choice for a range of applications. The shape of the part and specified tolerances typically determine which method to use—lathes for parts requiring concentricity or milling for angular components.

Industries that utilize CNC machining include:

• Aerospace and defense

• Automotive

• Consumer goods

• Electronics

• Industrial

• Medical and dental

• Robotics

Visit our CNC milling services and CNC turning services pages to learn more about inventory, surface finishing, applications, and other process advantages.

2. Extrusion

Extrusion involves pushing molten metal or plastic through a die. In practice, it is similar to squeezing a tube of toothpaste. The die creates a net shape, such as a tube, L-shape, or more complex features. Metal parts extruded typically require post-processing, such as cutting, drilling, or machining, and are ideal for manufacturing large quantities of parts that require a constant cross-section.

This is because extruded profiles can be almost any shape with a continuous cross-section. A good example is window frames, which use multiple functions to secure different panes within the assembly. They can even be hollow, such as square, round, or hexagonal tubes. Manufacturers determine the shape when creating the mold.

How Extrusion Works

The three types of extrusion include hot extrusion, cold extrusion, and friction extrusion. Hot extrusion uses high temperatures to prevent the work material from hardening. Cold extrusion uses temperatures close to room temperature, which is preferable to hot extrusion as it may result in stronger materials, less oxidation, or lower thresholds. Friction extrusion involves applying force to push the material toward the die.

Extruded Materials

Extruded materials can be plastic or metal. Approximately 80% of extruded metal components are aluminum alloys. Meanwhile, polyethylene is more common in plastic extrusion.

Applications and industries

Compared to other methods, extrusion is a simple process. Its mold costs are 80% to 90% lower than injection molding and die casting. Extrusion also provides a smoother surface for painting and finishing, making it an ideal choice for precision parts and decorative components, such as floors, windows, and railings. Automotive and aerospace components are also ideal applications for extrusion.

Extruded aluminum materials

3. Metal Casting Metal casting is a time-honoured manufacturing process. It involves pouring molten metal into a mould, allowing it to harden into the desired shape, and then cooling and removing it from the mould.

Modern metal casting is precise, automated, and supported by advanced tools, but the underlying principle remains the same. Its widespread use demonstrates the success of this method.

How it works

The metal casting process begins with pattern making. Before pouring the molten metal, a pattern is formed within the mould to create a hollow cavity of the desired shape. Modern pattern-making methods use precise calculations to achieve the required shape, which may include scaling to account for shrinkage and adding extra material thickness for subsequent CNC machining.

In many cases, the mould is destroyed during the casting process. This is an expected step in sand casting, where the sand-formed casting is broken down to reveal the finished product. New sand moulds are easy to make, and the sand is often recycled to create new moulds.

Metal casting may also involve the use of wax in a process known as investment casting. Manufacturers first create a wax model of the finished product. The wax is then covered with ceramic layers, which are heated and removed, leaving a ceramic mould with the wax pattern imprinted inside.

Both techniques have their advantages. For example, sand casting is a simpler process and easier to repeat. Investment casting requires more preparation but may perform better when manufacturing complex parts. Sand casting is typically more expensive; investment casting requires more labour to modify an existing design. Manufacturers must determine which process is more suitable based on their budget, labour constraints, and the quality of the parts they desire.

Metal casting is a versatile process. It supports any metal that can be formed into a liquid state, which is why engineers across industries use a variety of materials in metal casting. Aluminium, magnesium, and copper alloys are more common alloys, but manufacturers also use zinc, steel, and other metals.

Casting Use Cases and Industries

Today, almost all commercially produced mechanical equipment uses some form of casting. In mass production, casting typically offers cost and volume advantages over CNC machining. Metal casting can produce high-performance structural components for a wide range of applications, such as washing machines, automobiles, and metal pipes, all of which extensively utilise metal castings.

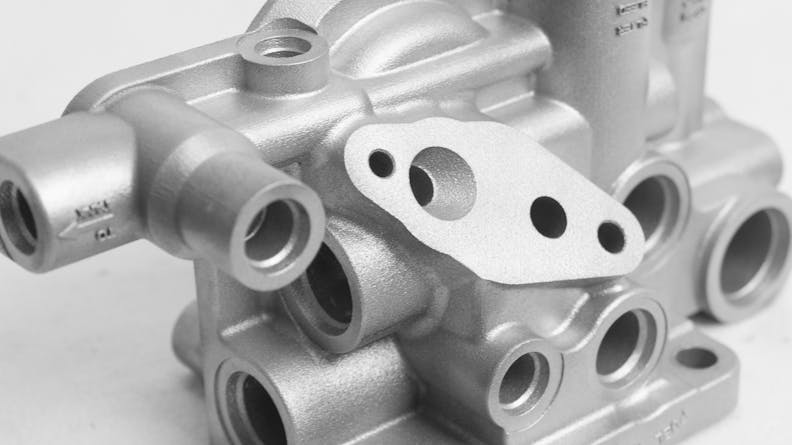

4. Die Casting

Die casting is an ideal choice for large-scale production of complex metal parts. Die casting uses steel moulds and low-melting-point metals as materials. Engineers utilise die casting for complex projects where precision, reliability, and high production volumes are critical. Die casting employs reusable hard tools similar to those used in injection moulding, resulting in smoother surface finishes while maintaining low costs for large-scale production.

How it works

In die casting, molten metal is forced into a mould under high hydraulic or pneumatic pressure, which differs from traditional metal casting where metal is poured into a mould. Manufacturers prefer die casting when producing parts with complex details, as pressure can more effectively create intricate and precise components.

Hot-chamber or ‘gooseneck’ die casting is the more popular method. The ‘gooseneck’ determines the shape of the metal feed system that delivers molten metal to the mould. Manufacturers use cold-chamber die casting to limit machine corrosion. In this method, molten metal is poured into the injection system, and in each of these methods, the process is similar to plastic injection moulding, where steel tools close and the part material flows into the mould cavity in the form of a hardened part. Once the hardened tools open, the parts either drop out automatically or are removed manually.

Die-casting materials

Die-casting manufacturers typically specialise in individual materials, including aluminium, zinc, and magnesium, as the raw material is molten metal used in conjunction with specialised die-casting machines. Approximately 80% of die-cast parts are made from aluminium. Zinc alloys are another low-melting-point metal commonly used in die-casting.

Use cases and industries

Die-cast parts have a wide range of applications. They are strong and heat-resistant, with smooth or textured surfaces. Die casting is advantageous for high production volumes, often outperforming CNC and investment casting, and widely supports painting, plating, and finishing. Additionally, die casting is an ideal choice for high-impact, high-stress equipment where strength is critical.

Contact Debaolong’s support team to inquire about more Debaolong Seiko die casting services.

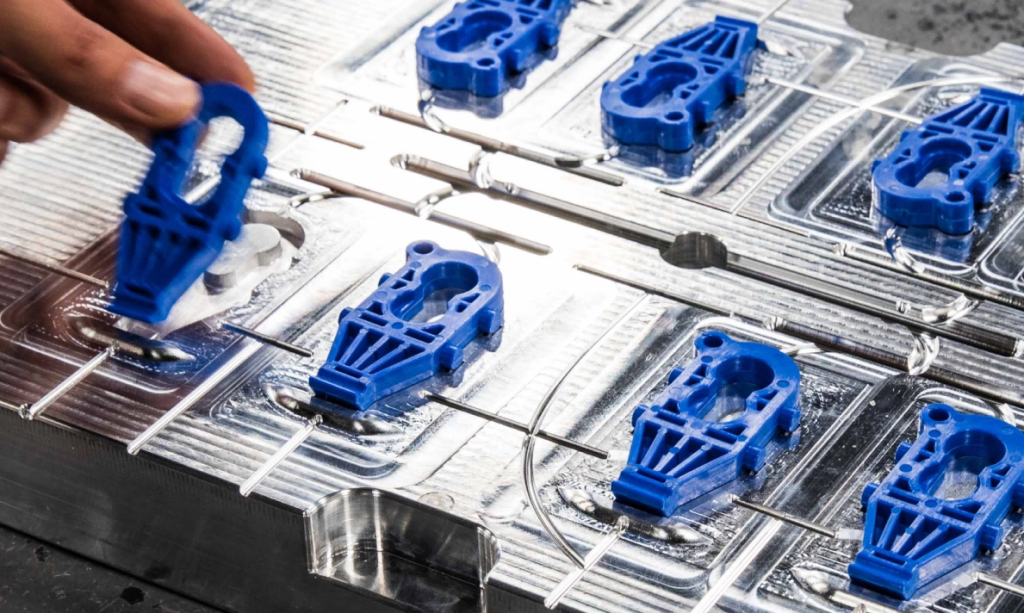

5. Metal Injection Moulding

Injection moulding is commonly used to manufacture plastic parts, but manufacturers also use injection services for metal parts. Even large-scale projects with high precision are cost-effective. While it is ideal for projects requiring small parts, metal injection moulding or MIM is actually suitable for parts of any size.

How it works

Unlike die casting, metal injection moulding uses a polymer-metal mixture as feedstock, where the melted plastic allows the material to flow when heated. During this process, the material is also pressurised, and the machine injects the liquid material into the mould, where it cools and takes the shape of the mould to form the part.

After moulding, the part is in a ‘green state,’ meaning it has the correct shape but is very fragile. The post-sintering process completely burns away the plastic, leaving only the melted metal. This sintering process is typically carried out in a vacuum furnace, and the parts experience significant shrinkage.

MIM Materials

Metal injection molding can be used with metals commonly found in other manufacturing processes; however, these metals must be converted into powder and mixed with the injection-grade polymer so that parts can be formed quickly and produced in large quantities.

Applications and Industries

Metal injection moulding is similar to the plastic injection moulding process used to manufacture parts, but the high-pressure characteristics of injection moulding provide key advantages. It is highly effective for parts with small, complex details, whereas large-scale standard CNC machining processes are too costly. This is why metal injection moulding is an ideal choice for the medical, aerospace, automotive, and defence industries.

Compared to die casting and other metal manufacturing methods, injection moulds have a longer service life, enabling the production of more parts before replacement or maintenance. In mass production or when finer part details are required, MIM typically outperforms die-cast parts, making it suitable for large-scale repetitive processes while offering manufacturers greater flexibility in terms of strength and unique properties.

6. Forging

Like metal casting, forging has been used for centuries. It is the process of heating and shaping metal parts under force. When thinking about forging, the familiar image of a blacksmith and an anvil comes to mind, but today, forging is widely used in automated industrial processes.

How it works

Modern forging uses high-impact machines to shape metal into the desired form. Compared to other methods, forging produces less waste, making it more cost-effective in practical applications.

Forged parts are typically stronger than parts manufactured using other methods. This is because forging utilises the natural texture of the material, which does not need to be reduced to a liquid state during shaping, but only heated to a malleable state.

Forging materials

Stainless steel is one of the most common forging materials. Aluminium and bronze are also commonly used forging materials.

Use Cases and Industries

Forging is an ideal choice for many industries, and its advantages and limitations make it an ideal process to use alongside other manufacturing materials. Common examples of components manufactured using this method for lifelong use include forged tools such as hammers or wrenches. Manufacturers should determine the application to leverage the advantages of forging in their business and output.

7. Sheet Metal and Stamping

Sheet metal manufacturing involves cutting parts from metal sheets and processing them using brakes and presses to form angled bends and shapes, thereby constructing three-dimensional structures. Sheet metal services specialise in stamping to quickly produce these parts. In fact, stamping is faster than any other metalworking process.

How It Works

Presses cut and bend parts from metal sheets. Workers feed the presses with cut or rolled metal sheets, and the machines straighten the metal as it is fed into the press. The strategic application of force allows manufacturers to adjust the shape of parts, bending them at specific angles to create the desired angles in the parts. Manufacturers use bending machines during this process, which come in various sizes and lengths to meet specific manufacturing requirements. Sheet metal parts can be welded or riveted to create structural components. Press-fit inserts such as PEM inserts can be added directly to create mating features such as bosses and threads without the need for custom machining.

Sheet Metal Materials

Sheet metal is typically made from aluminium, copper, or steel. Sheet metal also comes in a variety of finishes, including anodising, electroplating, powder coating, and painting.

Use Cases and Industries

Stamping makes sheet metal manufacturing highly scalable across any industry, making it an ideal choice for high-volume, low-unit-cost applications. Large-capacity functional components such as enclosures, chassis, and brackets are typically made from sheet metal parts.

However, the tooling costs for stamping are typically higher than other processes. Despite this, manufacturers produce billions of parts annually in the appliance, electronics, and automotive industries. Sheet metal and stamping are also the preferred choice for robotics.

Visit our sheet metal manufacturing services page to learn more about inventory, finishes, applications, and other process advantages.

8. Metal 3D Printing

Metal 3D printing services use precise lasers to manufacture metal parts, making them ideal for experimental and small-batch, high-value parts. Unlike many other metal processes listed, it is not scalable, so it is often used as an alternative to prototyping and small-batch casting.

How it works

3D printing, also known as additive manufacturing, fuses metal in a controlled environment using energy. Direct metal laser sintering (DMLS) melts metal powder layer by layer in an inert environment using a laser. Metal binder is sprayed to bond metal parts in a two-stage process, forming a green state before the metal is solidified in a secondary furnace process. Depending on requirements, binder jetting can produce metal composites, such as bronze and steel or single alloys. The unique feature of metal 3D printing is the ability to produce integrated components and geometries with inaccessible areas using standard tools. An example of features in inaccessible areas in traditional processes is the construction of lattice structures on parts. This is impossible with traditional casting moulding techniques. Even so, current technology would require more time and complexity to produce a single unit.

Metal 3D printing materials

The typical raw material for metal 3D printing is atomised powder, although sheet or wire materials can also be used. The printer follows a data path created from the 3D CAD file of the part to be produced. Common metal materials include powders of stainless steel, titanium, nickel-chromium-iron alloys, copper or aluminium.

The materials used in metal 3D printers typically come from powder metallurgy. Developing new materials for metal 3D printers requires extensive research to establish a reliable and repeatable method for manufacturing parts without failures or defects. This means that the range of materials currently available for metal 3D printing is much narrower compared to machining, metal casting, and other manufacturing methods.

Use Cases and Industries

Despite its limitations, metal 3D printing has nearly universal applications. Due to direct digital manufacturing, 3D-printed parts can typically be produced in small batches quickly without tooling costs, allowing engineers to experiment with 3D printing to begin production of almost any part and design parts specific to applications such as lightweight mechanical and aerospace components. Visit our Direct Metal Laser Sintering (DMLS) page or Metal 3D Printing Services page to learn more about how metal 3D printing can optimise your manufacturing processes.

Metal 3D printed parts via laser sintering and binder jetting

Debaolong Seiko meets all your manufacturing needs

How to successfully order the required parts? Debaolong seiko provides you with a wide range of customized services on demand, which are suitable for almost any industrial application.

Debaolong seiko supports dozens of processes with its huge professional production capacity, including CNC machining services, sheet metal processing services, injection molding, 3D printing and other services. Contacting us can help you process the required parts smoothly.