Turbochargers are pivotal components in modern engines, enhancing power, reducing fuel consumption, and minimizing emissions. At their core, turbo impellers, compressors, and turbines harness exhaust gas energy to compress air—understanding their material properties and manufacturing methods is essential for optimizing performance, durability, and reliability. This guide delves into the critical details of turbo impeller design, 优缺点 (advantages/disadvantages), and real-world applications.

What Is a Turbocharger Impeller?

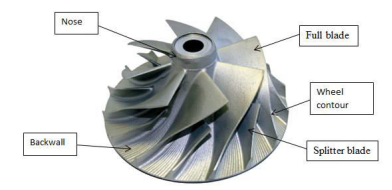

A turbocharger impeller is a rotating component inside a turbocharger that compresses incoming air for the engine. This compression enhances oxygen supply, improving fuel combustion efficiency and boosting torque and power. Designed aerodynamically, impellers must withstand high pressures and temperatures.

Turbo Impeller vs. Compressor Impeller

A turbocharger consists of a turbine impeller and a compressor impeller connected by a shaft:

- The turbine impeller spins via engine exhaust gases, driving the shaft.

- The compressor impeller draws in and compresses air, sending it to the engine to enhance combustion and power output.

Differentiating Impellers from Other Turbocharger Components

- Impeller: The rotating wheel that compresses intake air.

- Other Components: Turbine housings, compressor housings, or turbines serve distinct roles—turbines drive the compressor impeller using exhaust energy, while housings direct airflow.

How Does a Turbocharger Impeller Work?

Located on the intake side of the turbocharger, the impeller inhales and compresses air, which then flows to the engine to fuel combustion and generate high power. In short, it is critical for boosting engine performance.

How Turbocharger Impellers Enhance Engine Efficiency

Also known as compressor impellers, they improve efficiency by forcefully compressing air into the engine, enabling it to produce the same power with a smaller displacement. This ultimately enhances fuel economy and reduces emissions.

Impact of Impeller Speed and Flow on Power

Impeller rotational speed (RPM) and flow rate directly correlate with power demand: higher speeds and larger diameters yield higher flow rates, increasing power consumption—though this relationship is not always linear.

Why Impeller Size Is Crucial for Turbo Performance

Impeller size directly affects airflow, boost pressure, and engine power output. Optimized sizing ensures efficient airflow, maximizes boost, and avoids performance limitations like engine overload or turbo lag.

Turbocharger Impeller Design: Key Considerations

Several factors influence impeller design and performance:

Factors Shaping Impeller Geometry

Impeller design is heavily influenced by blade shape/angle, diameter, width, curvature, and flow velocity, impacting overall energy consumption, pressure, and efficiency.

Blade Profiles and Geometry

Blade profiles and geometry affect centrifugal pump performance, directly influencing factors like head, power output, and efficiency. Blade shape, angle, curvature, and quantity dictate flow patterns and energy transfer within the pump—optimizing these enhances efficiency.

Importance of Blade Angles

- Inlet Angle: Determines how fluid enters the impeller; optimized angles minimize turbulence and improve flow efficiency.

- Outlet Angle: Dictates how fluid exits the impeller, affecting generated pressure and head.

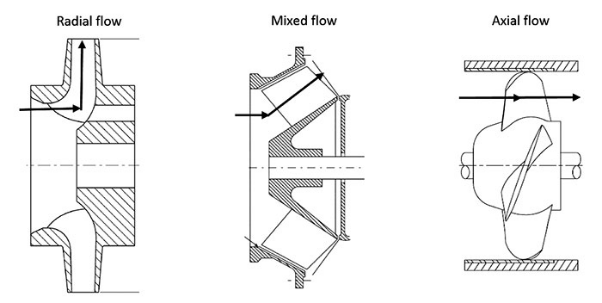

Radial vs. Axial Impeller Designs

- Axial Impellers: Direct fluid parallel to the shaft, ideal for high-flow, low-pressure applications like ventilation.

- Radial Impellers: Push fluid outward from the center, suitable for high-pressure applications like pipeline systems.

Types of Turbocharger Impellers

Impellers are classified by airflow direction:

Axial Flow Impellers

- Flow Pattern: Fluid moves parallel to the shaft (top-to-bottom).

- Advantages:

- Efficient for high-volume, low-pressure applications.

- Promote vertical flow to suspend solids in liquids, preventing sedimentation.

- Suit stratified liquid layers in tanks.

- Achieve high RPM with low energy input.

- Disadvantages:

- Unsuitable for high-viscosity fluids.

- Prone to vortexing if baffles are misaligned.

- Expensive due to large propeller blades.

- Applications:

- Mixing fluids requiring solid suspension.

- Low-head water pumping for irrigation and flood control.

- Circulating water in power plant cooling systems.

- Liquid circulation in chemical processes (evaporation, crystallization).

- Wastewater treatment for sewage digestion.

Radial Flow Impellers

- Flow Pattern: Blades perpendicular to the shaft push fluid outward radially, generating high pressure and low flow.

- Advantages:

- Ideal for high-pressure applications (e.g., high-altitude pumping).

- Provide strong shear force for mixing viscous materials (e.g., pigment pastes).

- Handle fluids with varying temperatures and viscosities.

- Efficiently convert mechanical energy to fluid flow.

- Suit gas dispersion tasks.

- Disadvantages:

- Sensitive to viscosity changes.

- Lower flow rates than other impellers.

- Prone to vortexing in certain applications.

- Applications:

- High-pressure water supply and irrigation.

- Firefighting systems.

- Industrial pumps (circulation, machine tools, boiler feedwater).

- Mixing and dispersing for uniform mixtures.

- Multi-stage pumps for high discharge pressure.

Mixed Flow Impellers

- Flow Pattern: Combine radial and axial flow characteristics, suitable for medium-pressure applications.

- Advantages:

- Handle fluids with varying densities and viscosities.

- Efficient for medium-head applications.

- Pump turbid liquids with suspended solids.

- Offer versatile flow patterns.

- Disadvantages:

- More complex (higher manufacturing costs) than radial/axial impellers.

- Unsuitable for extreme low/high head applications.

- Limited speed range between radial/axial designs.

- Applications:

- Water supply and distribution systems.

- Large-scale irrigation.

- Cooling system applications.

- Handling contaminated or turbid liquids.

- Paper mill pulp pumping.

- Marine jet propulsion systems.

Common Materials for Turbocharger Impellers

Key materials include stainless steel, titanium alloys, nickel-based alloys, and composites, chosen for heat resistance and lightweight properties:

Stainless Steel Alloys

- Examples: AISI 4063 steel, low-carbon C1045ss (carbon steel, less common for impellers than stainless steel).

- Advantages: High strength, corrosion resistance, suitable for high-temperature/high-pressure environments.

Nickel-Based Alloys vs. Aluminum Alloys

- Nickel-Based Alloys (e.g., Inconel 718): Preferred for turbine impellers due to high-temperature resistance and strength.

- Aluminum Alloys: Used for compressor impellers due to low density, reducing inertia and improving engine response.

Titanium Alloys in Impellers

Titanium alloys balance strength, corrosion resistance, and lightweight properties, making them ideal for high-temperature, high-speed applications in both compressors and turbines.

Composites in Lightweight Impellers

- Materials: Carbon fiber-reinforced polymers (CFRP), fiberglass.

- Advantages: Significantly reduce weight compared to metal impellers, with high strength and durability.

- Limitations: Less common than stainless steel, used in specific applications to avoid failure.

Turbocharger Impeller Coatings

Coatings enhance performance and durability:

- PVD/PACVD Coatings: Prevent scratching, wear, and frictional oxidation.

- Carbon-Based Coatings: Low friction coefficient, suitable for low-lubrication conditions.

How to Manufacture Precision Impellers?

Impellers’ complex geometry relies on 5-axis CNC machining, though challenges include high initial costs and specialized training.

5-Axis CNC Machining for Impellers

- Process: Uses 5-axis CNC machines to control movements along A, B, X, Y, and Z axes, enabling complex shapes impossible with 3-axis machining.

- Advantages:

- High precision and accuracy for tool path control.

- Creates intricate blade features via multi-directional tool movement.

- Efficient, reduces setup time and manual intervention.

- Achieves critical aerodynamic surface finishes.

- Disadvantages:

- Higher initial costs than 3-axis machines.

- Requires specialized operator training.

- Risks material deformation in thin-walled parts.

Key Stages of Impeller Machining

- Create a 3D CAD model of the impeller.

- Select materials (titanium, aluminum, stainless steel).

- Choose cutting tools (ball-end mills, end mills).

- Generate CNC programming code from the CAD model.

- Clamp the workpiece and set up the machine.

- Machine the impeller via roughing and finishing operations.

- Thoroughly inspect the finished impeller.

How to Choose the Right Turbocharger Impeller for Your Engine

Consider these factors:

Selecting Impellers by Engine Type

Engine size and type dictate airflow and boost pressure needs:

- Small impellers offer faster boost response.

- Large impellers deliver higher peak power.

- Factor in vehicle usage and fuel type.

Matching Impeller Type to Performance Goals

- Impeller type (compressor/turbine), size, shape, blade count/angle, and housing compatibility all impact performance.

Material Considerations for Impeller Durability

- Common materials: Stainless steel, aluminum, titanium alloys—chosen for strength, corrosion resistance, and heat tolerance.

- Impeller materials must withstand high speeds and temperatures.

Conclusion

Turbocharger impellers are indispensable for enhancing engine power and efficiency, designed to compress intake air for improved combustion and torque. Their manufacturing process spans design, material selection, and precision 5-axis machining—ensuring optimal performance in modern powertrain systems.

For more information, please contact us at Debaolong Seiko.