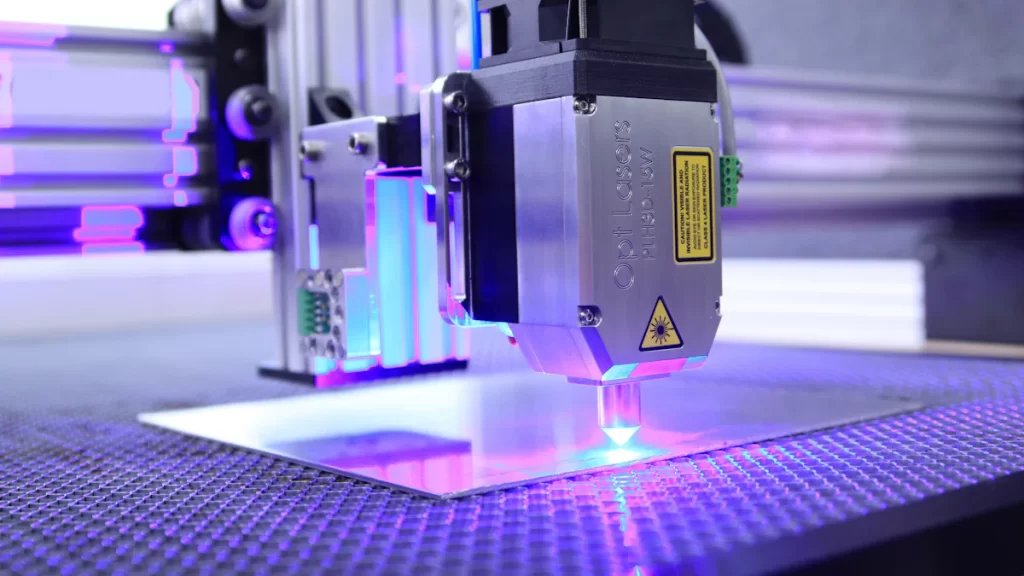

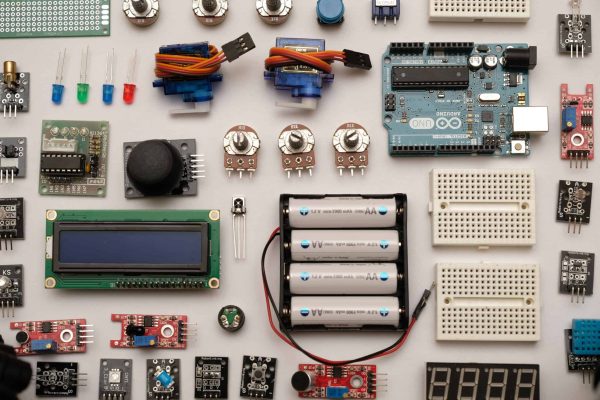

3D printing, as a manufacturing process, offers numerous advantages to produce fully functional components for diverse industries and operational conditions. Parts printed with 3D technology are often used in high-temperature applications, requiring heat-resistant materials to ensure proper functionality. This article introduces several top heat-resistant 3D printing materials suitable for high-temperature use.

More Heat-Resistant 3D Materials

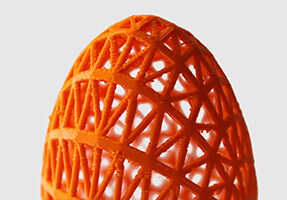

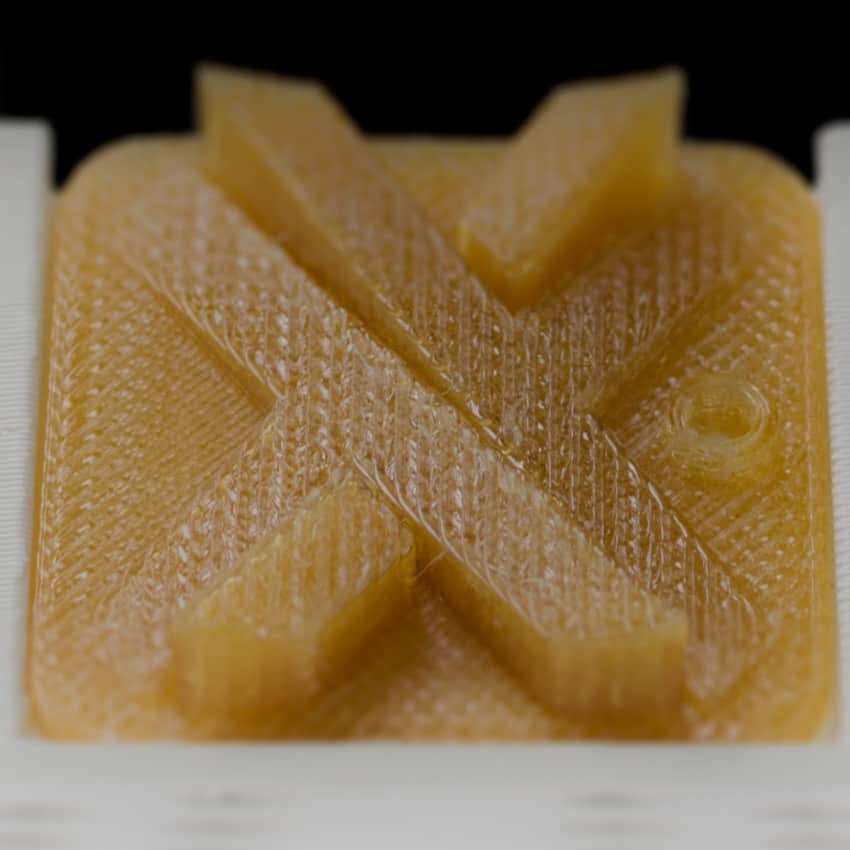

Acrylonitrile Butadiene Styrene (ABS)

ABS can withstand temperatures up to 100°C, with a heat deflection temperature (HDT) range of 88–89°C and a melting point of ~200°C. Renowned for its toughness and impact resistance, ABS is ideal for printing components under high-stress conditions. It has a glass transition temperature (Tg) of ~105°C and resists acidic aqueous solutions, phosphoric acid, and hydrochloric acid.

- Technology: Fused Deposition Modeling (FDM)

- Key Features: Chemical resistance, impact resistance

- Common Applications: Drain/waste pipes, inhalers, electronic component housings

ABS FDM 3D printed part

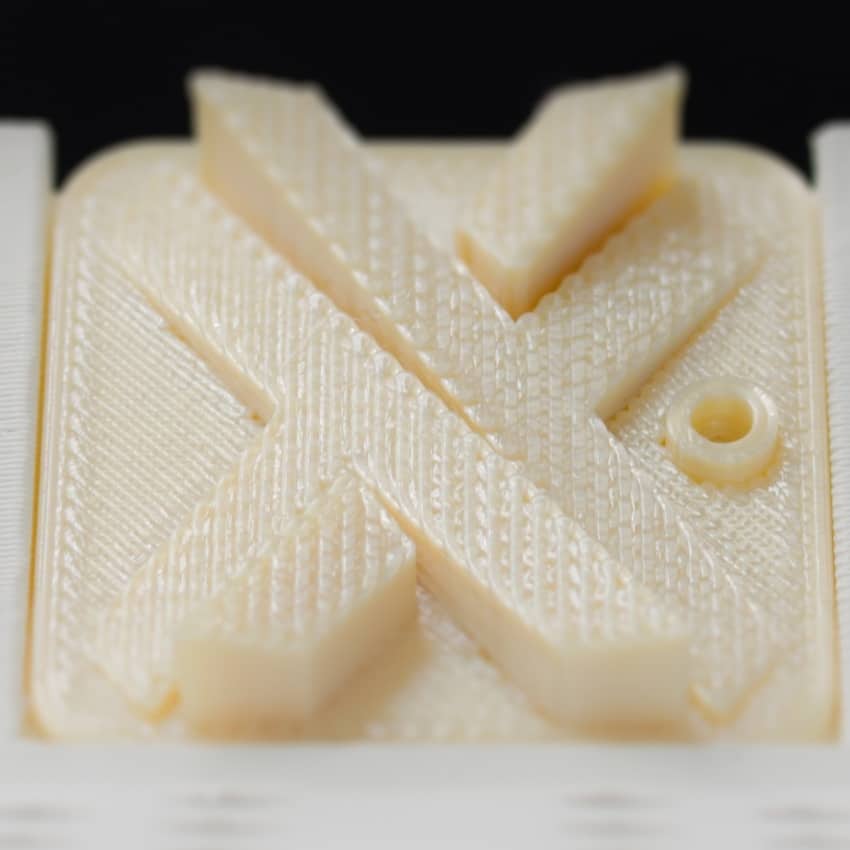

ULTEM 1010

Compared to other FDM materials, ULTEM 1010 exhibits superior heat resistance, chemical resistance, and tensile strength. Available in transparent, opaque, and glass-filled grades, it is widely used in custom tooling (metal/plastic component machining), medical tools, and heat-resistant molds.

ULTEM 1010 is a high-performance polyetherimide thermoplastic with a melting point of 340°C and a Tg of 216°C. It has an extremely low coefficient of thermal expansion, is food-contact safe, and biocompatible—making it ideal for the food industry.

- Technology: Fused Deposition Modeling (FDM)

- Key Features: Excellent heat resistance, tensile strength, low thermal expansion

- Common Applications: Medical tools, heat-resistant molds

ULTEM 1010 FDM 3D printed part

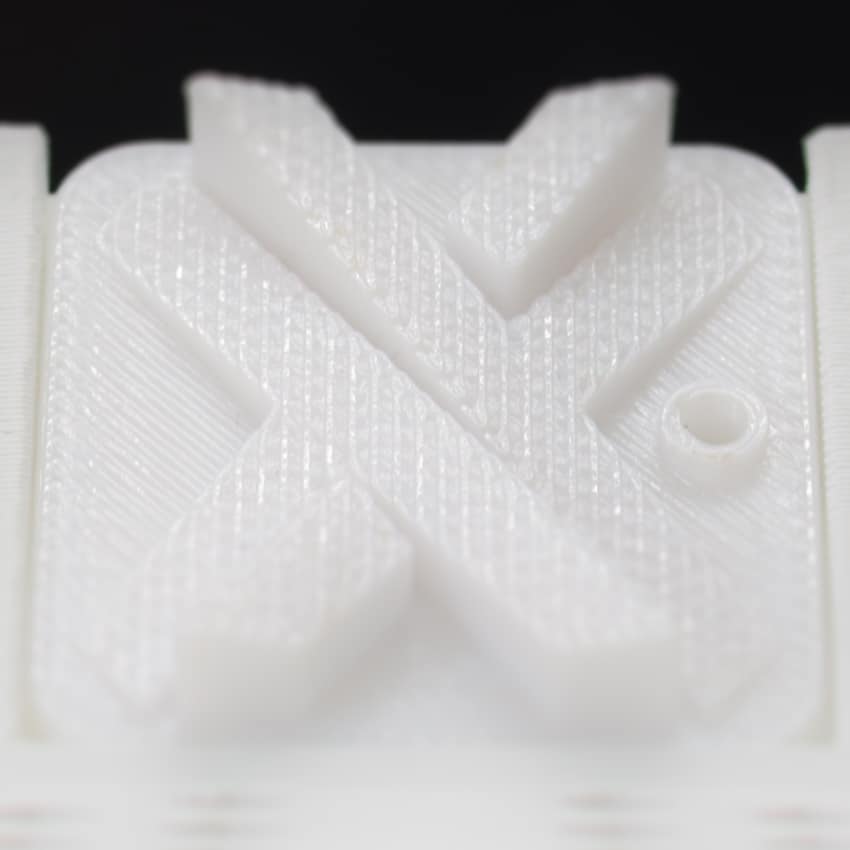

ULTEM 9085

Featuring a high strength-to-weight ratio, impact resistance, and heat resistance, ULTEM 9085 is flame-retardant, suitable for aerospace and automotive prototyping and tooling. It has a Tg of 186°C and HDT of 153°C, making it strong and lightweight for end-use components.

- Technology: Fused Deposition Modeling (FDM)

- Key Features: Flame retardancy, impact resistance

- Common Applications: Drill jigs, fixtures, composite molds

ULTEM 9085 FDM 3D printed part

Polycarbonate (PC)

With a crystalline melting point of ~230–260°C and Tg of 147°C, PC is a tough amorphous material with high impact strength, excellent stability, and superior electrical properties. It operates across a wide temperature range (HDT 140°C) and is used in safety helmets, automotive headlight lenses, and bulletproof glass.

- Technology: Fused Deposition Modeling (FDM)

- Key Features: Translucent, flexible

- Common Applications: Plastic lenses for goggles, protective gear, automotive parts

Polycarbonate FDM 3D printed part

Polyether Ether Ketone (PEEK)

PEEK resists aggressive chemicals, offers high mechanical strength and dimensional stability, with a melting point of 343°C and Tg of 143°C. It maintains rigidity at high temperatures, suitable for continuous use up to 170°C, and is applied in aerospace, oil & gas, and semiconductor manufacturing.

- Technology: Fused Deposition Modeling (FDM)

- Key Features: Chemical resistance, high rigidity, steam/water resistance

- Common Applications: Semiconductor components, valve/pump assemblies, food processing machinery

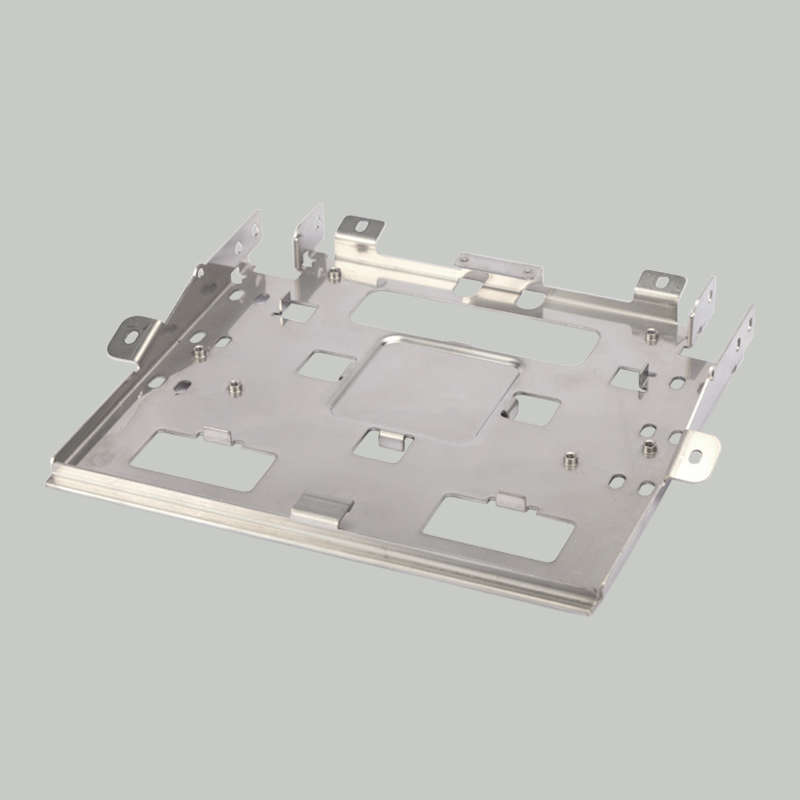

AlSiMg Aluminum

AlSiMg aluminum retains high strength at ~200°C, with excellent corrosion resistance and polishability. It offers good workability, thermal cracking resistance, a melting point of 670°C, and fatigue strength of 110N/mm². Suitable for complex geometries, it is widely used in vehicle, machinery, and aircraft components, with a room-temperature tensile strength of 290MPa.

- Technology: Selective Laser Melting (SLM)

- Key Features: Lightweight, compressive strength

- Common Applications: Electric motors, engine components

1706 Aluminum DMLS 3D printed part

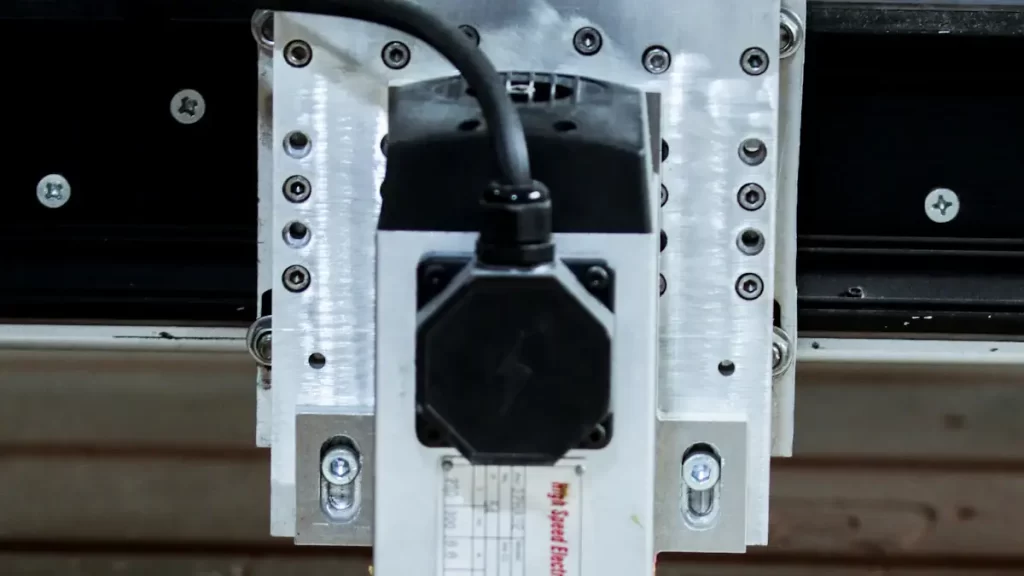

316L Stainless Steel

316L stainless steel withstands continuous use at 925°C, belongs to chromium-nickel-molybdenum stainless steels with low carbon content, and has a melting point of 1400°C. It shows excellent corrosion resistance and stability in chloride-based media and non-oxidizing acids, suitable for aerospace, medical, and automotive industries.

- Technology: Selective Laser Melting (SLM)

- Key Features: Corrosion resistance, ductility

- Common Applications: Laboratory equipment, heat exchangers, nuts/bolts

316L Stainless Steel DMLS 3D printed part

Inconel 718 (Nickel-Chromium Superalloy)

Inconel 718 is a high-strength nickel-chromium superalloy resistant to corrosion, extreme pressure, and temperatures up to 700°C, with a melting point of ~1400°C and tensile strength of 1035 MPa. It requires hard cutting tools and is used in manufacturing, military equipment, and aerospace.

- Technology: Selective Laser Melting (SLM)

- Key Features: Corrosion resistance, high mechanical strength

- Common Applications: Gas turbine engine components, compressor casings, mold holders

TCT Titanium Alloy

TC4 titanium alloy offers moderate room-temperature and high-temperature strength, good creep resistance, thermal stability, high fatigue resistance, crack propagation resistance in seawater, satisfactory fracture toughness, and thermal salt stress corrosion resistance.

- Technology: Selective Laser Melting (SLM)

- Key Features: High strength, heat resistance, corrosion resistance

- Common Applications: Engine compressor blades, ultrasonic molds

Properties Table of Heat-Resistant 3D Materials

| Material | Melting Point | Glass Transition Temperature | Tensile Strength |

|---|---|---|---|

| ABS | 200°C | 105°C | 42.5–44.8 MPa |

| ULTEM 1010 | 340°C | 216°C | 105 MPa |

| ULTEM 9085 | – | 186°C | 71.6 MPa |

| PC | 230–260°C | 147°C | 60 MPa |

| PEEK | 343°C | 143°C | 110 MPa |

| AlSiMg Aluminum | 670°C | – | 205 MPa |

| 316L Stainless Steel | 1,400°C | – | 490–690 MPa |

| Inconel 718 | 1,370–1,430°C | – | 965 MPa |

| TCT Titanium Alloy | 1700°C | – | 1150 MPa |

Price Comparison of Heat-Resistant 3D Materials

| Material | 3D Printing Technology | Price per Gram |

|---|---|---|

| ABS | FDM | ¥1–3 |

| ULTEM 1010 | FDM | Custom quote |

| ULTEM 9085 | FDM | Custom quote |

| PC | FDM | ¥1–3 |

| PEEK | FDM | Custom quote |

| AlSiMg Aluminum | SLM | ¥2–4 |

| 316L Stainless Steel | SLM | ¥1–3 |

| Inconel 718 | SLM | Custom quote |

| TCT Titanium Alloy | SLM | ¥12–18 |

Conclusion

With a range of heat-resistant materials, Debaolong Seiko provides efficient, reliable, and high-precision online 3D printing services. We provide a full range of services from quotation to door-to-door delivery to protect your parts production.