Tips for Cost Savings in 3D Printing

Although 3D printing technology offers numerous advantages, one of the main concerns when using it is cost. From design to manufacturing and post-processing, certain techniques can significantly impact costs. This article highlights useful tips for saving costs during the 3D printing process.

Tips to Reduce Costs at Each Stage of 3D Printing

This section is divided into three parts based on different stages of the 3D printing process, providing tips to minimize costs wherever possible. Details are as follows:

Reduce Costs Through Design

Hollow 3D Models

Hollowing is an effective way to reduce material usage and lower 3D printing costs. Hollowing removes internal material from a part, leaving only a shell. It also serves as a good method for creating lightweight components. If you plan to use 3D printing technologies that use powder materials, such as Selective Laser Sintering (SLS) or HP Multi-Jet Fusion (MJF), consider designing parts to be hollow.

(Solid part on the left vs. hollowed part on the right)

Check the Dimensions of Your 3D Printed Object

The size of your 3D printed object directly affects the printing cost. If the dimensions of your prototype are not critical (e.g., visual prototypes), scaling down the model can significantly reduce costs. In fact, 3D printing prices are proportional to the volume occupied by the object on the machine’s build platform. To lower costs, reconsider the dimensions of your object in CAD software.

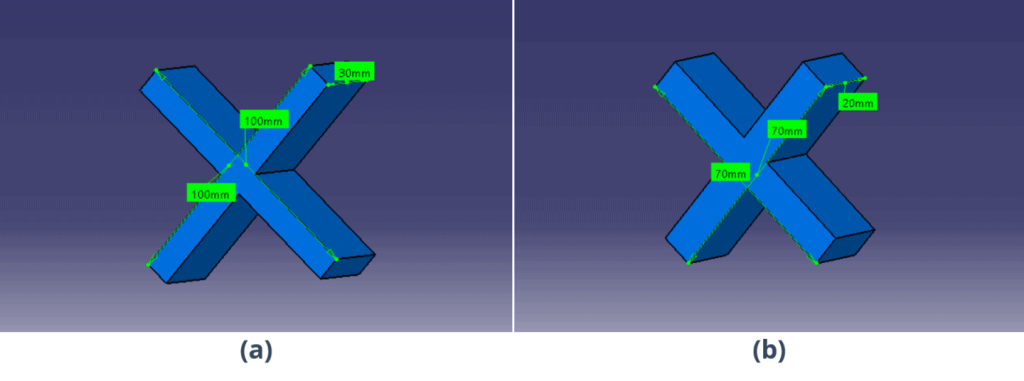

Let’s compare the costs of model (a) and its scaled-down version (b):

| Technology | Unit cost (€) for a | Unit cost (€) for b | Unit cost per 100 pieces (€) for a | Unit cost per 100 pieces (€) for b |

|---|---|---|---|---|

| FDM | 18.54 | 10.57 | 5.69 | 3.00 |

| MJF | 26.75 | 24.30 | 16.36 | 7.68 |

The cost comparison clearly shows that the scaled-down model is cheaper.

Optimize Design

A well-designed 3D printed part can maximize material usage, reducing unnecessary costs. Here are some tips:

- Use gradual transitions to connect adjacent surfaces.

- Avoid sharp corners, which often generate residual stress in finished workpieces.

- Ensure unsupported thin walls are not too tall, as they may bend or deform.

- Surfaces with shallow angles often exhibit unsightly “stepping,” making them unsuitable for aesthetic features and requiring post-processing to eliminate—thereby increasing costs.

- Adopt intelligent design.

Reduce Costs by Choosing Appropriate Manufacturing Options

Select Suitable Materials

The best way to reduce material costs is to ensure you choose the right material for your needs. If you’re printing a part that’s only a visual model, it’s likely unnecessary to use expensive Continuous Liquid Interface Production (CLIP) resins. High-performance materials like polyetherimide (ULTEM) are always pricier than materials such as polyamide (PA) or polylactic acid (PLA). Thus, rational material selection helps cut costs.

Choose the Right Process

Compared to Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM) and HP Multi-Jet Fusion (MJF) are much cheaper, with materials that are easily accessible and inexpensive. Therefore, clarify your requirements first. If you use 3D printing for prototyping or visual models, FDM, SLS, or MJF can all meet your needs well. For high-tech requirements and premium printing, consider processes like Digital Light Processing (DLP), Stereolithography (SLA), Rigid Light Polymer Technology, or Direct Metal Laser Sintering (DMLS).

Evaluate Production Volume

For single-piece or low-volume production (<100 units), 3D printing is the better choice. For mass production, consider CNC machining or even injection molding instead. If the design is complex and cannot be achieved by traditional machining, 3D printing is an option; but if the design is simple and the batch is large, avoid using 3D printing from a cost perspective.

Reduce Costs During Post-Processing

Eliminate Support Structures

Processes like HP Multi-Jet Fusion (MJF) or Selective Laser Sintering (SLS) do not require support structures when building parts, while FDM does. During post-processing, these support structures need to be removed, leading to material waste and extra costs. To avoid additional expenses in post-processing, check if your parts can be manufactured using powder-based technologies like SLS or MJF.

Choose Post-Processing Techniques

Post-processing sometimes requires manual work, which increases 3D printing costs. For example, dyeing is usually cheaper than painting because it’s a faster technique—though painting offers better color durability and higher quality. FDM and MJF provide colored 3D printing without extra coloring, which can be considered for cost reduction. Processes like vapor smoothing to refine surface texture also add costs. Choose the most suitable technique based on your needs.

SLS-printed nylon dyed green

Conclusion

3D printing costs can be reduced at every stage: design, manufacturing, and post-processing. By following our recommendations, you can ensure your 3D printing costs remain reasonable. Feel free to upload your design to Debaolong Seiko for a quote and to compare design iterations and possible manufacturing options.