In recent years, 3D printing, as a rapidly emerging manufacturing technology, has not only been increasingly applied in industrial fields but also gradually become an essential part of the workflow for hobbyists and enthusiasts. This article introduces 10 DIY open-source project ideas that blend fun and challenge, helping you unleash the full potential of 3D printing technology.

1. OpenRC Formula 1 Toy Car

This fully open-source 3D printing project for a remote-controlled (RC) Formula 1 toy car allows you and your printer to showcase skills in a racing context. A fun community project, it has attracted numerous participants who exchange various modification plans, tutorials, and insights. It can be modified to your required specifications and printed to your desired size (up to over 150 cm in length). Ideal for learning about RC systems, OpenRC F1 lets you and your printer shine on the track.

Recommended materials and processes: Durable ABS material is recommended, with cost-effective processes like FDM and MJF.

2. Dragonfly Technology

This 3D-printed dragonfly is an excellent open-source project to kill idle time. Inspired by the extraordinary flight mechanics of real dragonflies, this small device is powered by a wound rubber band. The project aims to deepen enthusiasts’ understanding of flight characteristics.

Recommended materials and processes: Lightweight and flexible PP or PLA materials are recommended, with economical and durable processes like FDM and MJF.

3. Hovercraft

Originally a student project, this DIY hovercraft serves as a preliminary attempt to build an affordable mobile scientific research station for the Arctic. As a significant 3D printing project, most of its components are 3D printed, while the base is made of cut foam plastic.

Recommended materials and processes: ABS material is recommended for a sturdy structure, with processes like FDM or MJF.

4. DIY Quadcopter

This 3D-printed FPV (first-person view) quadcopter is lightweight and drop-resistant, effectively protecting onboard equipment. Although this 3D printing project has higher costs, there are 24 design options on Thingiverse to meet different budget needs. You can view project introductions and relevant materials via the links below.

Recommended materials and processes: While PLA is usable, ABS performs better in drop resistance. As shown in the photo, the top is printed with PLA, and the bottom with ABS. Processes like FDM or MJF are recommended.

5. Strandbeest – Beach Beast

The Strandbeest is a cool 3D-printed kinetic sculpture that combines engineering and art. Driven by wind, it slowly wanders on Dutch beaches. You can build your own DIY Strandbeest and enjoy the fun. Composed of eight individual components, the Strandbeest is assembled through sequential repetition.

Recommended materials and processes: Affordable nylon is recommended for flexible moving parts. Processes like MJF, FDM, or SLS can be chosen based on cost.

6. Robotic Arm

The 5-axis robotic arm is another fun and challenging open-source project. Developed by a team of professional engineers, multiple components can be 3D printed. It uses not only printed parts but also stepper motors and an Arduino. The robotic arm is equipped with Zortrax stepper motors specially developed for robotics.

Image source: Thingiverse

Recommended materials and processes: PLA and PC are ideal for high-strength, functional parts. For this project, FDM is the optimal and economical choice.

7. Self-Watering Planter

Worried about watering plants while traveling? No need to fret—print your solution now. This simple 3D-printed Self – watering flower pot makes maintaining plants that need frequent watering easier. You only need a common glass jar filled with water. Place the 3D-printed planter with soil and plants (seeds or seedlings) on the jar. Leave space for drainage if needed. The benefit is that the transparent jar makes the water level visible at a glance.

Recommended materials and processes: PETG is the most suitable plastic for printing waterproof components. As the filament is easily accessible, it is also suitable for FDM printing.

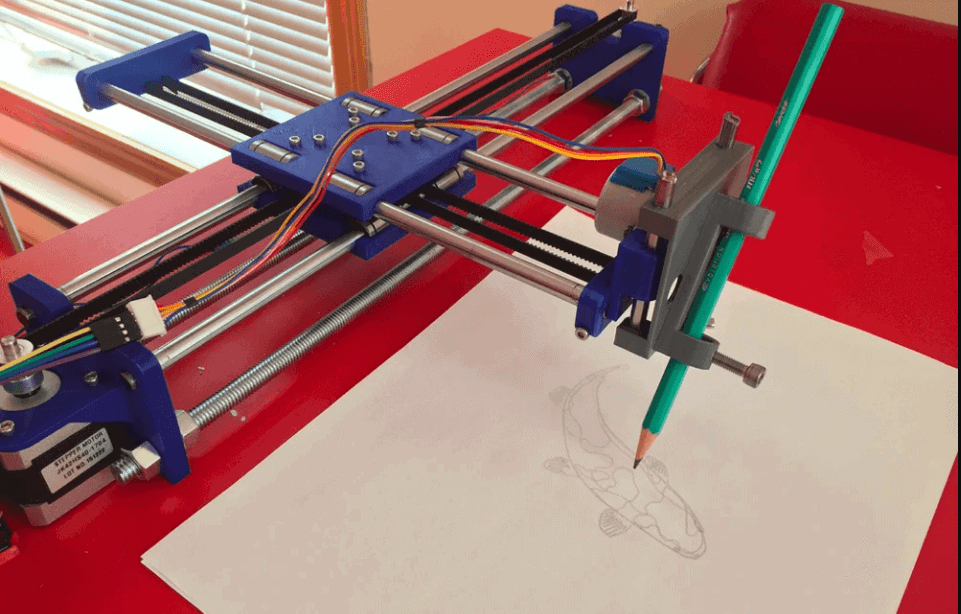

8. Plotter

A plotter is ideal for creating greeting cards, formal invitations, and more. This partially 3D-printed plotter makes the work process easy and enjoyable. It can hold any pen and create exquisite works and cool paper art through raster files.

Recommended materials and processes: High-strength materials like ABS, PC, and PLA are suitable for this purpose, with processes like FDM or MJF.

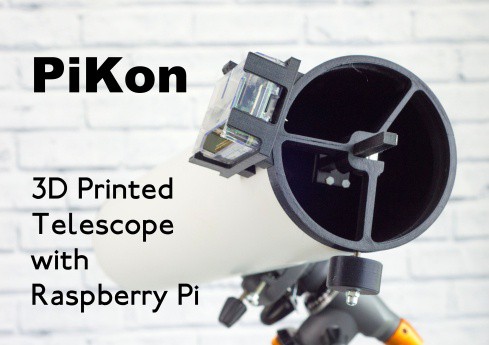

9. PiKon Telescope

Are you interested in stargazing? If so, this cool project is perfect for you. The PiKon telescope, manufactured via 3D printing and equipped with a Raspberry Pi system, allows you to observe the starry sky on a screen at a lower cost for components.

Recommended materials and processes: The project mainly uses PVC pipes as the telescope tube, and other components can be made of PLA to balance durability and economy. Processes like FDM or MJF are recommended.

10. DIY Camera Slider

For photographers, high-quality equipment is often expensive. This 3D-printed project for a motorized camera slider vividly demonstrates 3D printing’s ability to create affordable items needed by consumers. It uses a PVC pipe as the slider and is driven by a DC motor.

Recommended materials and processes: Nylon or PLA are the most economical choices for these plastic parts, with low-cost processes like FDM and MJF supporting multi-color filament printing.

Welcome to visit Debaolong Seiko for quotes and to order your 3D printed products!