PETG is an extremely popular 3D printing filament, widely used for its high strength, relative flexibility, and heat resistance compared to the equally popular PLA. It is relatively easy to print, even on inexpensive printers without enclosures, making it perfect for practical parts that require more toughness before breaking than PLA offers. Thanks to its mechanical properties, it has replaced ABS as the second most popular 3D printing filament on the market.

But what exactly is PETG? What are its best applications? And how on earth can we get this sticky stuff to print well? We’ll answer all these questions and more, so let’s start with the basics.

01 What Is PETG?

PETG stands for Polyethylene Terephthalate Glycol-modified. It’s similar to PET used in disposable plastic bottles but with ethylene glycol added to improve extrusion and printing characteristics—such as reducing shrinkage. Thanks to ethylene glycol, PETG is much easier to print.

In terms of mechanical properties, this material has moderate heat resistance: a maximum continuous operating temperature of about 45°C (depending on load) under low creep conditions. It also features moderate impact resistance, moderate ultimate tensile strength, and moderate flexibility, making it a good all-around material compared to PLA and ABS.

PETG is also a moderately hygroscopic material, meaning it absorbs moisture from the air. While it may be more hygroscopic than PLA, it’s far less so than materials like nylon.

02 Applications

Thanks to its mechanical properties, PETG is a material suitable for functional prototypes or end-use parts. While it falls short compared to ABS, it makes up for this with its far more forgiving printability. For example, an enclosure isn’t needed to get PETG parts with good mechanical properties.

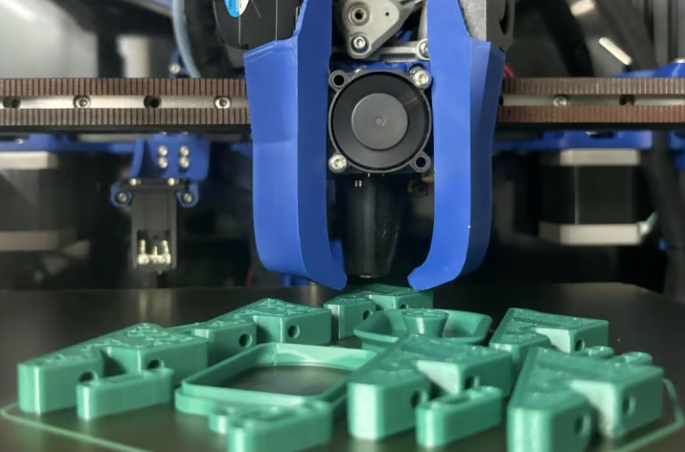

PETG is commonly used for 3D printer parts (especially open-frame printers), small robotic components, and jigs and fixtures. In such functional applications, parts may be exposed to slightly higher temperatures and need to exhibit long-term low creep to maintain operability.

Another interesting application of PETG is printing highly transparent objects. Since natural PETG is transparent, this can be achieved by printing very slowly and over-extruding to fill in the gaps between lines, creating a pore-free part that prevents light scattering (which can cause cloudiness) and maintains optical transparency.

Finally, PETG is generally considered food-contact safe, but you should consult the manufacturer to ensure their processing meets food safety standards. Check out our article on food-contact safe filaments for some compliant PETG options. If you plan to print kitchenware with PETG, make sure your printer, extrusion system, and nozzle (avoid brass) are thoroughly cleaned.

03 The Trouble with PETG

Generally speaking, PETG is an easy material to print—almost as easy as PLA. However, there are a few things to keep in mind.

3D printing PETG requires slightly higher temperatures than PLA, which may also affect your printer settings. For example, if you haven’t already, you might want to consider upgrading to an all-metal hot end—see hardware recommendations below.

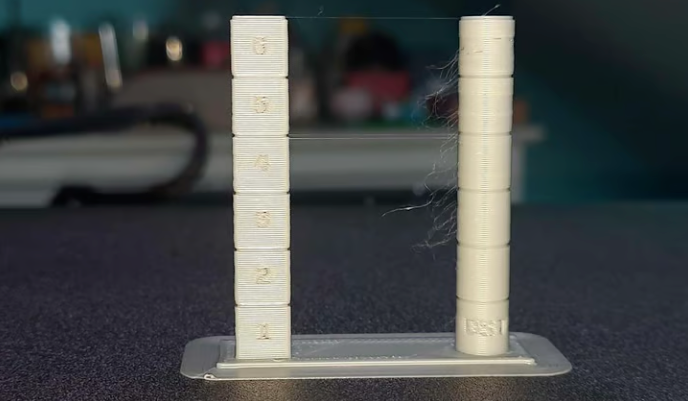

While you can freely let your printer’s part cooling fan blast away at PLA, PETG may exhibit significantly weaker interlayer adhesion if excessive part cooling is used. Therefore, part cooling should be more carefully controlled with PETG to achieve good overhangs while maintaining interlayer bond strength. Thankfully, PETG is still very forgiving in this regard compared to ABS and engineering filaments.

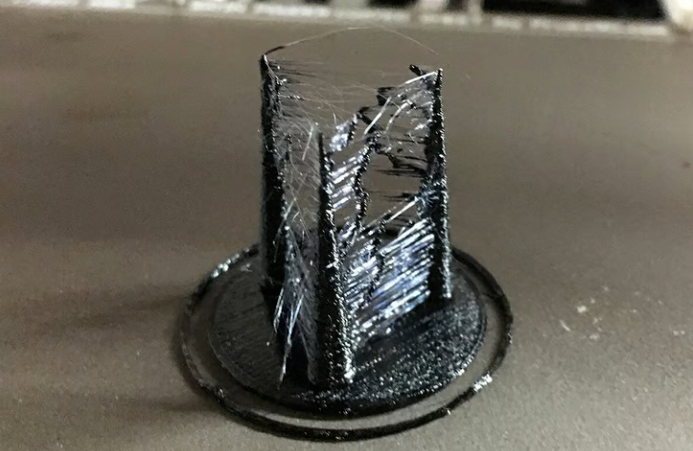

Finally, PETG is more prone to stringing than most rigid filaments, partly due to its hygroscopic nature and printing temperature requirements. We outline some tips in the common printing issues section below.

04 Hardware Recommendations

PETG is typically printed at nozzle temperatures of 225–255°C, so a PTFE-lined hot end is sufficient. PTFE-lined hot ends can withstand 240°C for extended periods and 260°C for short prints. However, an all-metal hot end is strongly recommended. With it, you can safely print at the upper end of the PETG temperature range, which is important for good interlayer adhesion and better flow rates.

Regarding nozzles, PETG is a non-abrasive material, so a standard brass nozzle can be used. That said, some prefer nozzles with a non-stick coating. Due to its stringing properties, filament can sometimes adhere to the side of the nozzle and start to accumulate. Therefore, a nickel-plated copper nozzle helps prevent PETG from sticking to the nozzle tip.

The build surface is a particularly important consideration for PETG. Like many other materials, it adheres extremely well to popular PEI-based build plates—maybe even too well. Sometimes it can be difficult or impossible to remove your print without damaging the underlying PEI layer, especially on smooth PEI surfaces. Therefore, using hairspray or solid glue as a release layer for prints on the build plate is recommended. The same should be done for glass build plates, as PETG typically adheres too well to glass.

Finally, while PETG doesn’t require a heated enclosure, an enclosure benefits part strength. The internal chamber temperature should be relatively low: up to 45°C. Ensure not to exceed this temperature, as PETG’s glass transition point is relatively low, potentially causing thermal creep.

05 Print Setting Recommendations

When it comes to slicing models for PETG printing, PETG’s print settings are similar to other non-flexible filaments. Chances are, you can use a standard print profile for PETG and get decent results. Of course, the usual temperature adjustments still apply.

PETG prints at nozzle temperatures of 225–255°C and bed temperatures of 65–75°C. Like most materials, we recommend leaning toward the upper end of the nozzle temperature range for better part strength and higher flow rates.

In terms of speed, we recommend 20–40 mm/s in other guides, but the maximum print speed depends on your specific printing system, including your motion system, hot end flow rate, and many other factors. To tune the best speed settings for your specific device, we recommend performing a speed test print with the PETG filament you plan to use.

PETG’s retraction settings are also comparable to other rigid filaments. The recommended retraction distance depends on the type of extruder you have: about 3–5 mm for Bowden extruders and 0.5–1 mm for direct drive extruders. Regardless of your printer’s extruder type, we recommend a retraction speed of about 25–45 mm/s. However, these values are for reference only, especially for PETG, which is prone to stringing. For best results, ensure you further adjust retraction settings based on your exact extruder, hot end system, and speed settings.

You definitely need to adjust the cooling settings. For PETG, cooling is a balance between interlayer bond strength and overhang performance. In our guide, we recommend setting the fan between 20% and 50%, but some in the community believe PETG can be printed without part cooling for medium-sized models. If you’re printing models with short layer times, the recommended reduced fan speed will help. Of course, you can adjust the fan speed based on your settings to achieve satisfactory print performance.

Finally, additional bed adhesion settings like brims and rafts are usually unnecessary; PETG tends to stick well to the build plate.

- Nozzle temperature: 225–255°C

- Bed temperature: 65–75°C

- Print speed: Adjust based on your printer settings

- Retraction distance: ~3–5 mm (Bowden), ~0.5–1 mm (direct drive)

- Retraction speed: ~25–45 mm/s

- Part cooling: Adjust based on your printer settings

- Brims and rafts: Not needed

06 Common Printing Issues

When printing with PETG, you may encounter some common printing defects that require troubleshooting. Here are some issues you might face and possible solutions.

Stringing

Users often find PETG more prone to stringing than other filaments. Since this is partly due to hygroscopicity, remember to dry the filament before printing for optimal results. A good estimate for PETG is drying at 65°C for 4–6 hours.

To tune out the last bit of stringing, PETG may also require more precise retraction settings, which you should adjust for best results. If all else fails or you’re short on time, a heat gun is a great way to remove those fine strings from the final print.

Poor Layer Adhesion

As mentioned, PETG can suffer from poor layer adhesion if part cooling is excessive or hot end temperatures are too low. To alleviate this, you can reduce part cooling or increase print temperature to enhance interlayer bonding. But remember, this may result in worse overhangs or increased stringing—it’s all about balance.

Additionally, if you’re printing at or near the hot end’s maximum volumetric flow rate, it’s worth considering reducing the print speed. Printing faster than the hot end’s maximum flow rate can cause the material to melt insufficiently before extrusion, leading to layer adhesion issues.

07 Removal & Post-Processing

Let’s start with removing the finished print from the build plate. As mentioned, PETG can over-adhere to smooth PEI or glass surfaces if a release agent isn’t used. If you still can’t remove the print from the build plate even after it has cooled to room temperature, you might consider putting the build plate in the freezer. The theory is that this works via thermal contraction: the build plate shrinks more than the part.

For a smoother outer surface, sanding is recommended—especially since solvent polishing PETG can be difficult. This material is somewhere between PLA (hardest to sand) and ABS (easiest to sand) in terms of sanding difficulty. Like most other sanding techniques, starting with coarser sandpaper and moving to finer grades is recommended for the best results.

Since you’re likely using PETG for functional parts, it can be easily drilled without gumming up if you need precision features.

Finally, PETG can also be coated with different epoxies to give your prints a glossy finish. For food-contact prints, food-contact safe epoxies can make your PETG prints suitable for holding food and beverages.

For more information, please contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quotation.