In daily life, we often use components such as nuts and bolts to connect two or more parts. These joints allow us to create strong and safe structures for critical applications. There are various types or shapes of these components (i.e., pin fasteners), and this article will help you understand them, how they are used, and more.

What are Pin Fasteners?

You may have seen carpenters use nails to connect two pieces of wood, or manufacturers use nuts and bolts to join two metal plates. These joints that connect two or more plates or components are called pin fasteners. Let’s delve into the details of these pin fasteners:

How Pin Fasteners Work

Their work is not that arduous or complex. Holes are drilled in the desired components, and then these pins are inserted into these holes. These pins provide easy component installation in a cost-effective manner.

Advantages of Using Pin Fasteners

You will learn about some important advantages of pin fasteners in this section:

Durability and Longevity

Pins are made of materials such as carbon steel and stainless steel, which have high strength and wear resistance, enhancing durability and service life.

Universal Application

You will find pin fasteners used in fields ranging from construction to aerospace, making them versatile tools.

Easy Installation and Maintenance

They can be installed by simply pressing these tools into appropriately sized holes on the parts. That’s why they are easy to use.

Cost-Effectiveness

Lower assembly, disassembly, and maintenance costs make them a very economical connection tool.

Safety and Adjustable Features

Pin fasteners are designed to be very strong, so they can provide a very secure connection. Their more adjustable design ensures proper safety.

20 Types of Pin Fasteners

Now, let’s briefly introduce the types of pin fasteners:

Cotter Pins

Used to gently secure parts together. The following picture shows a cotter pin.

Uses and Applications

- Used in securing polymer packaging, rubber, and in the automotive industry.

- Provide simple and safe connection.

Materials and Durability

- These pins are made of low-carbon steel or stainless steel.

- Can withstand mechanical loads and resist corrosion in harsh conditions.

Dowel Pins

As shown in the figure, these pins are cylindrical. They are inserted into pre-drilled holes in components to achieve connection between parts.

Functionality and Precision

- Provide precise fastening and alignment of components.

- Used in furniture and machine assembly.

Standard Sizes and Variants

- Available in various standard sizes.

- Not affected by materials.

Lynch Pins

They pass through the end of a shaft to keep a wheel in place.

Features and Locking Mechanism

- Self-locking mechanism.

- Enable quick and safe connection.

Applications in Agriculture and Construction

- Can be used to secure axles and other components in the agricultural field.

- Used for partial connections in the construction field.

Spring Pins

These pins can be used to firmly connect multiple components by simply pressing them into holes.

Design and Flexibility

- Elastic fasteners.

- Expand and fit firmly on components.

Types of Spring Pins (Slotted Spring Pins vs. Coiled Spring Pins)

- Slotted pins are used for hard materials and steel components.

- Coiled pin fasteners: more flexible and can absorb shocks and vibrations.

Wire Lock Pins

As shown in the figure, components are locked by the wire on the pin.

How They Work

- Simply tighten the wire on the pin to lock parts, etc.

Main Advantages for High-Security Applications

- Eliminate the loss of cotter pins.

- A reliable choice in critical scenarios.

Taper Pins

To establish a connection in rotating components, taper pins can be used.

Tapered Design and Function

- The tapered design supports its function, i.e., effective locking and precise alignment.

Common Uses in Machinery

- In wheels of tractors, automobiles, etc.

- Manage repeated assembly and disassembly.

L-Handle Pins

This type of pin fastener has an L-shaped handle for easy gripping.

Overview and Features

- L-shaped pin fasteners have functions such as quick locking and adjustment.

Common Industries and Uses

- Agricultural industry.

- Used in handling settings.

U-Bolts

These pins are unthreaded and reusable, serving the same purpose, i.e., firm connection.

Function and Application

- Connect moving parts.

- Often used in the agricultural field.

Importance of Safety and Rigidity

- Firm fastening enhances safety and rigidity.

Locating Pins

Also known as quick-release pins.

Designed to establish connections.

Mechanism and Locking Process

- Insert the pin into the desired application hole.

- Push the lock open.

- Pull the pin to unlock.

Common Applications in Industrial Equipment

- Outdoor and mobile equipment.

- Construction machinery.

- Marine applications.

Hitch Pins

To secure equipment or accessories to a tractor through holes in a hitch receiver or coupler, you should use these pins.

Features and Variations

- Known as heavy-duty fasteners, used for trailers and towing vehicles.

Common Uses in Vehicles and Machinery

- Connection between trailers and vehicles.

- Recliner furniture.

- Agricultural equipment.

- Lawn equipment.

Grooved Pins

The locking mechanism is to press the fastener into a properly sized hole. These fasteners are unthreaded and press-fitted.

Applications in Precision Engineering

- Locking devices.

- Fulcrums.

- Bearings.

- Positioning elements in assemblies.

Advantages Over Other Pin Types

- Enhance grip and stability.

- A stronger lock to prevent loosening due to vibration.

Spring Pins

No additional tools are needed; just snap into place.

U-shaped pin fasteners, which work similarly to bayonet pins, are known for ease of use.

Quick and Easy Installation

- User-friendly pins are known for their quick and simple installation.

Key Applications in Quick-Release Systems

- Outdoor equipment and machinery, as these fields require quick release.

Bent Pins

One end of this pin fastener is bent at a 90-degree angle; its name also reflects this design.

Unique Design and Advantages

- The design of this pin has a 90o bend, which makes it very unique. This uniqueness allows us to easily install and handle them.

Industries That Need to Use Bent Pins

- Mainly used for additional fixation.

- Automobiles and trailers.

- Agricultural equipment (plows, rakes).

- Marine industry.

- Aerospace.

Thumb Tacks

A thumb tack has a very sharp end that can be inserted into a surface. The other end has a head, making it easier to push the thumb tack in.

Quick and Easy Fixation of Lightweight Materials

- These pins are most suitable for lightweight materials, and you can often see them in offices.

Common Uses in Office and Home Applications

- Used to push newspapers on bulletin boards.

Expansion Pins

These pins have two prongs that, when activated, expand toward the center and position the part.

Expanding Design for Secure Fixation

- Provide adjustable fasteners, ultimately offering a safe connection.

Applications Requiring Strong Locking Force

- Automotive industry (gear assemblies).

- Structural parts in the aerospace field.

Rivet Pins

These pins have a protrusion on one end and do not require a bent end. Just press these pins to install them into components, etc.

Compression Mechanism for Secure Connection

- Press the hump to ensure a firm connection.

Used in Assembly and Structural Applications

- Various mechanical systems use this type of pin fastener.

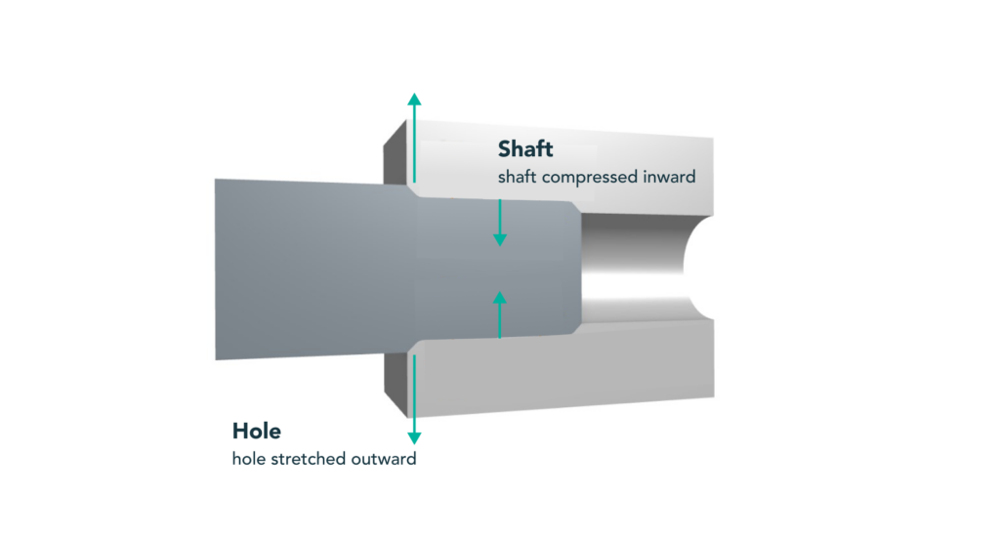

Tension Pins

A unique pin design capable of resisting tension when connecting two or more components.

Designed to Withstand Pulling Forces

- The following figure shows the design of the pin, which can resist tension.

Designed to Withstand Pulling Forces

Common Uses in High-Pressure Environments

- Axle and wheel assemblies in automobiles.

- Flight control mechanisms.

- Rail vehicle coupling systems.

Floating Pins

It can move within the hole during use, which is why it cannot permanently lock components.

Flexible Design for Adjustable Positioning

- Adopt different designs to adjust misalignment.

Applications Requiring Movement or Alignment Adjustment

- Used in flexible applications.

- Steering links.

Fixing Pins

Its design is like that of a spring, which helps it to be firmly fixed in its position once installed.

Used to Secure Components in Place

- It provides operational reliability.

Common in Mechanical and Automotive Assemblies

- Used to fix bearings, gears, and shafts.

- Piston pins.

- Connecting rods and arms in industrial machinery.

Safety Pins

- Spring-based working mechanism.

- Easy to operate.

- Only lock the covered area.

Securely Fasten Textiles and Fabrics

- These pins can be used to fix softer materials, such as fabrics.

Popular in the Garment and Crafts Industries

- Due to the low strength of the pins, they can be used in the garment and crafts industries.

Common Materials for Manufacturing Pin Fasteners

These are the materials used to manufacture pin fasteners:

Steel (Carbon Steel, Stainless Steel)

Steel has high strength and corrosion resistance.

Aluminum and Other Lightweight Materials

Aluminum is ideal for the aerospace industry due to its light weight, electrical conductivity, and corrosion resistance.

Brass and Bronze with Corrosion Resistance

To make the appearance beautiful and corrosion-resistant, use brass and bronze.

Manufacturing Methods of Pin Fasteners

The manufacturing methods of pin fasteners are as follows:

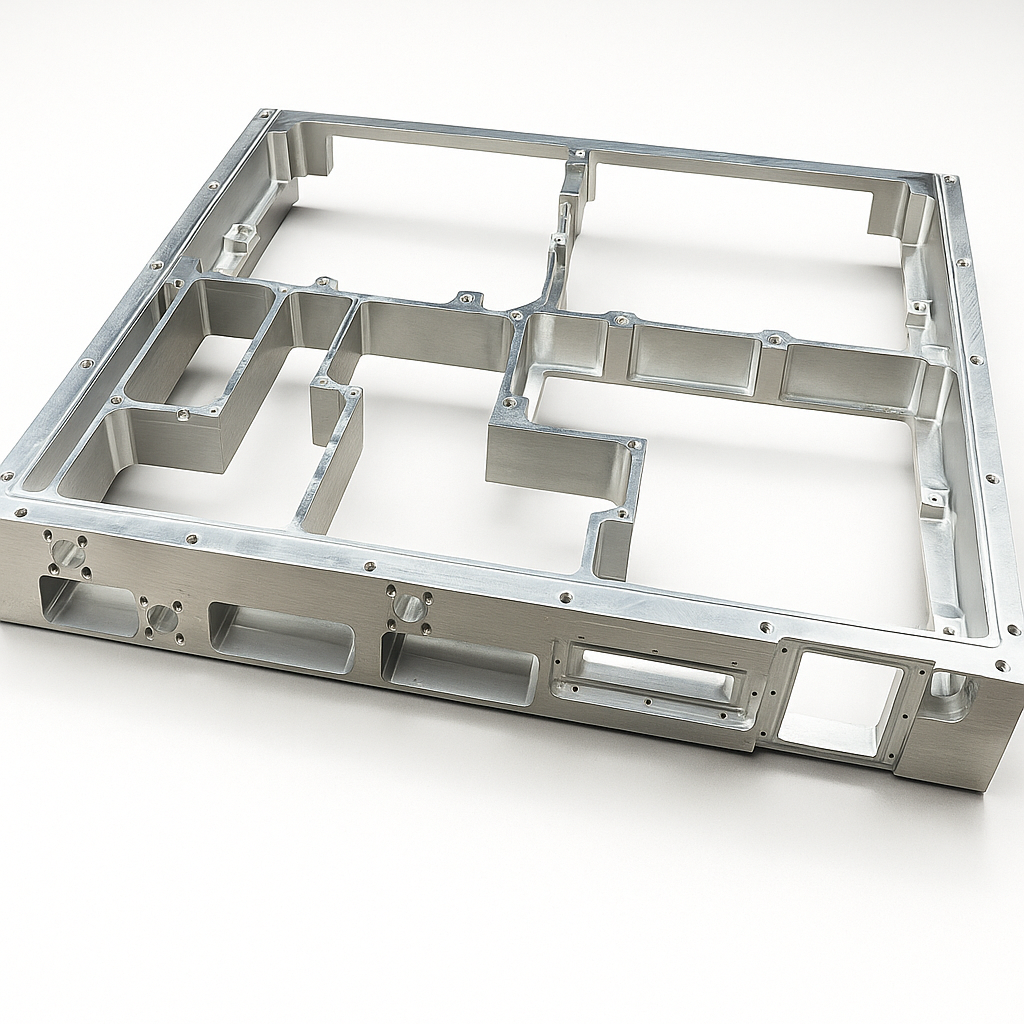

Precision CNC Machining

To produce pins with 100% qualified dimensions, a very advanced machine is needed, which is a CNC machine.

Stamping and Die Cutting

After selecting the appropriate material, the stamping process is adopted, followed by die cutting.

High-Strength Forging Applications

Forging is essential for manufacturing processes to obtain higher strength.

How to Choose the Right Pin for Your Project

We discussed various shapes of pins earlier. Now let’s talk about how to choose the right pin:

Consider Material Requirements

Do you require high strength? Please use pins made of steel.

Size and Shape Selection

First, measure the size of the hole or the thickness of the material, then select the corresponding pin shape.

Load Capacity and Strength Considerations

This is an important factor to prevent failures during application.

Environmental Resistance (Corrosion, Temperature, etc.)

Environmental factors are important considerations as they can ultimately lead to failures.

Common Applications of Pin Fasteners

Let’s take a look at these applications:

Automotive Industry

These pins are used to ensure safe connection of components during manufacturing.

Pin Fasteners in Vehicle Assembly

To achieve reliable connection:

- Body assembly

- Engine

- Suspension system

Pin Fasteners in Suspension Systems

Thanks to pin fasteners, the suspension system of vehicles can operate safely and effectively.

Medical Industry

The uses of these pins in the medical industry are:

- Maintain the integrity of materials.

- Enhance safety.

Use of Pins in Medical Devices

Used for safe assembly of:

- Surgical instruments

- Medical machinery

Safety and Precision in Medical Applications

These pins can provide precise alignment, thereby improving safety and accuracy.

Industrial and Mechanical Applications

Reliable and strong fastening makes pin fasteners usable in industrial and mechanical applications.

Pins in Equipment Assembly

Used to fix the following components:

- Engines

- Pumps

- Manufacturing machines

Quick Assembly and Disassembly Pins

Quick assembly and disassembly can minimize downtime during maintenance.

Cooperate with Debaolong Seiko for Custom Pin Fasteners

We will tell you why you should choose Debaolong Seiko for custom pin fasteners:

Why Choose Debaolong Seiko?

You should order from Debaolong Seiko because:

- Precision CNC machines are also suitable for metal pins.

- Low cost of manufacturing processes.

- On-time delivery.

CNC Machining Expertise

Debaolong Seiko has the best CNC operators who ensure strict tolerances when manufacturing metal pins.

Custom Solutions for Each Industry

Debaolong Seiko will efficiently produce custom pins suitable for corresponding purposes for you.

Conclusion

Pin fasteners can firmly connect two or more components, whether it is a temporary or permanent connection. These tools or components have more than 20 shapes, each with its own uses. These pins are easy to carry, operate, and install, and have advantages such as replaceable parts. Before choosing pin fasteners, many factors should be considered, such as load.