Whether you’re restoring a classic car or modifying an electric vehicle with a custom chassis, choosing the right chassis is the first step in any modification project. This guide breaks down today’s chassis types, demonstrates how custom frames can reduce weight and improve handling responsiveness, and outlines each design and manufacturing milestone—all explained in clear, easy-to-understand language to help you get started immediately.

What Is a Car Chassis?

The car chassis is the vehicle’s skeleton. It connects the engine, suspension, and body while absorbing bumps and impact forces. Without a strong chassis, even the best engine cannot provide safe, responsive handling.

Body-on-Frame vs. Unibody: Key Differences

- Body-on-Frame – A ladder-type steel structure with the body bolted to it. Ideal for trucks and heavy-duty towing vehicles.

- Unibody (Monocoque) – A one-piece welded shell consisting of the floor, roof, and pillars. Lighter and stronger, more common in passenger cars.

Both layouts affect collision repair costs, weight distribution, and aftermarket upgrade paths, so choose the architecture that best aligns with your payload, handling, and budget goals.

Core Functions: Strength, Crash Protection, Handling

A good chassis resists bending, protects the cabin during collisions, and maintains stable wheel alignment for predictable steering. It also channels braking loads and road impacts along safe paths, prevents squeaks, and preserves panel gaps after years of use.

How Chassis Geometry Affects Ride Quality

Wheelbase, track width, and suspension mounting points determine a vehicle’s responsiveness and comfort. A longer wheelbase smooths out bumps, while a wider track reduces body roll. Camber gain or anti-dive features can enhance feedback without compromising daily drivability.

Common Car Chassis Types Explained

The automotive industry uses four main architectures, each solving different design challenges.

| Chassis Type | First Used | Best For | Typical Materials | Weight Trend |

|---|---|---|---|---|

| Ladder Frame | 1900s | Heavy trucks, 4×4s | Mild steel | Heavy |

| Backbone Frame | 1960s | Sports cars | Box-section steel spine | Medium |

| Unibody | 1940s | Most passenger cars | Pressed steel, aluminum | Light |

| Space/Tubular Frame | 1930s | Race cars and kit cars | Round steel/aluminum tubing | Very light |

Ladder Frame

A dual-rail design that’s simple and strong but heavy. Crossmembers can be welded anywhere for custom mounting, but the high center of gravity affects cornering—manufacturers often add roll cages or gussets to boost rigidity.

Backbone Frame

A central spine carries drivetrain loads, reducing weight for small-displacement sports cars. Side-impact strength requires extra box sections, but this layout frees up sill space for sleeker styling and easier side exhaust routing.

Unibody

Stamped panels are spot-welded into a rigid shell with integrated crash zones. This reduces weight and costs but requires factory fixtures for repairs and careful corrosion protection to maintain long-term strength.

Space Frame and Tubular Designs

Triangulated tubing offers exceptional stiffness per kilogram. Engineers mix steel and aluminum components to tune compressive properties, but extensive welding demands precision jigs and skilled labor, increasing manufacturing time.

Why Choose a Custom Car Chassis?

Mass-produced frames work for average drivers. Enthusiasts and niche OEMs want more.

Lighter and Stronger

Reducing weight by 15–25% while increasing torsional stiffness by 30% cuts lap times and fuel consumption. Less weight means faster acceleration and shorter braking distances, while greater rigidity maintains window seals and prevents dashboard rattles for years.

Powertrain Freedom

Custom rails and brackets accommodate batteries, mid-mounted engines, or hybrid transmissions. Designers can slide firewalls, lower floors, or reverse differentials—layouts impossible with factory-stamped rails.

Sharper Handling

Custom pickup points lock in camber gain, anti-dive, and roll center heights for predictable response. Drivers feel quicker steering, balanced cornering, and even tire wear, even during long highway drives.

How to Design a Custom Chassis Project?

Safe, roadworthy structures start on screens long before pipes reach the welder.

Best Materials for Custom Chassis

| Material Family | Typical Grades/Conditions | Tensile Strength (MPa) | Density (g/cm³) | Practical Advantages | Practical Disadvantages |

|---|---|---|---|---|---|

| High-Strength Steel | DP800, 4130 (normalized), 22MnB5 (press-hardened) | 800–1,500 | 7.8 | Lowest $/kN cost, easy to weld/form | Heavier; galvanic corrosion with aluminum bolts |

| Aluminum Alloys | 6061-T6, 6082-T6, 7075-T6 | 310–570 | 2.7 | 35–50% lighter than steel; CNC-friendly | Requires thicker sections; 7075 cracks when welded |

| Composites | Carbon fiber T700/T800, S-glass/epoxy | 600–4,000 (fiber) | 1.6–2.0 | Best stiffness-to-weight ratio; corrosion-resistant | High cost; labor-intensive layup; hard to repair |

- High-Strength Steel

Modern dual-phase and martensitic steels match chromoly tubing strength without special gases. Press-hardened 22MnB5 rails reach ≥1,500 MPa—ideal for crash buffers and roll cages. - Aluminum

- 6061-T6 weighs half as much as steel but hits 310 MPa tensile strength.

- 6082-T6 adds ~10% strength and better fatigue life, perfect for EV floors.

- 7075-T6 jumps to 570 MPa but resists welding—builders form it in soft O-temper, then post-age to T6 and bolt/rivet components.

- Composites

T700 carbon fiber prepreg tubes achieve 4,000 Nm/degree torsional stiffness at ultra-low weights. Aluminum extrusion cones bond into laminates, dispersing bolt loads without bulky steel inserts.

Rule of thumb: Match materials to your budget and joining method first; chase ultimate strength only after solving welding, bonding, or riveting constraints.

Predicting Loads and Tuning Stiffness

Engineers map tire forces, then iterate finite element analysis (FEA) until torsional stiffness hits targets. Simulations reveal stress hotspots early, letting teams trim excess metal and reinforce weak joints before cutting real tubing.

Ensuring Safety and Crashworthiness

Identify applicable standards (FMVSS, ECE, JNCAP). Rails and joints must crush progressively during impacts, absorbing energy before it reaches the cabin. Virtual sled tests guide gusset sizes and trigger beads, ensuring prototypes pass physical crash lab tests on the first try.

Reducing Custom Chassis Costs

Modular jigs and one-stop CNC partnerships cut labor, shipping, and tolerance drift. Shared fixtures cover multiple wheelbases, while single-facility logistics prevent damage or misalignment between outsourced steps.

Manufacturing Methods for Custom Chassis Components

Precision matters from raw tubing to painted frames.

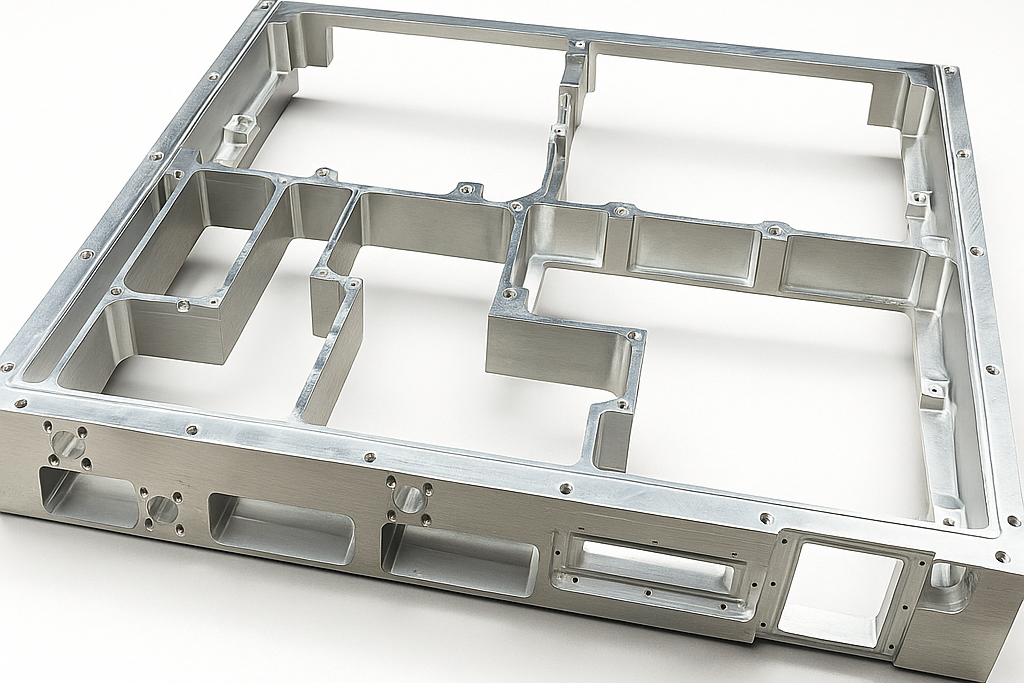

CNC Precision Machining

5-axis mills achieve ±0.02mm accuracy—critical for suspension knuckles and steering bushings. In-cycle probes check every recess, eliminating manual reaming for builders and ensuring bolt holes align on the first try.

Sheet Metal Fabrication

Waterjet and bending lines fold 2–3mm aluminum tubs with tight radii and minimal heat. Integrated flanges speed welding/riveting, boosting strength while controlling costs.

Corrosion-Resistant Finishes

Zinc spray, electrophoretic coating, or clear anodizing resists 1,000+ hours of salt spray. 配套的底漆系统使油漆紧密结合,即使在严酷的冬季路面上也能保持展厅般的光泽。

Integrating Suspension and Drivetrain into Custom Frames

Geometry and service access determine long-term satisfaction.

Setting Suspension Pickup Points

Laser-cut tabs fix arms within ±0.1mm, locking in camber gain, scrub radius, and bump steer. Later adjustments need only shims, saving track-side setup time.

Modular Subframes for Easy Maintenance

Drop-down brackets mount engines and transmissions on isolated bushings. Accessible bolt service cuts maintenance time by half, lowering fleet costs and simplifying weekend power upgrades.

Noise, Vibration, and Harshness (NVH) Management

Hydroformed rails and rubber mounts dampen noise above 200Hz. Strategic foam fills and composite panels suppress mid-frequency resonance, keeping cabins quiet even with stiff springs and low-profile tires.

Choosing the Right Custom Chassis Partner

Execution quality determines project success.

Essential Engineering and CAD Capabilities

Look for suppliers with CATIA, SolidWorks, and validated crash models. Proven simulation skills mean they can predict performance before cutting metal, shortening prototyping cycles.

Quality Certifications and Testing Facilities

ISO 9001, PPAP documentation, metallurgical micrographs, and weld tensile tests ensure robust process control. Reliable records guarantee frames meet specs.

From Prototype to Mass Production

How to scale custom chassis projects? Partnering with a specialized CNC machining facility helps. Debaolong Seiko, a precision CNC parts manufacturer with nearly 20 years of experience in custom machining, offers shared fixtures—meaning prototype and production frames undergo the same quality checks, drastically cutting lead times.

Conclusion

Custom chassis reduce weight, shrink packaging, and boost handling. Collaborate early with experts who integrate design, FEA, and machining to turn sketches into road-ready metal—without overspending.

For more information, contact Debaolong Seiko. You’re also welcome to upload your designs to Debaolong Seiko for a quote.