A high-quality knife requires both hardness and a sharp edge. In this regard, high-carbon steel excels. This article explains why high-carbon steel knives are so common and their drawbacks.

What Is High-Carbon Steel?

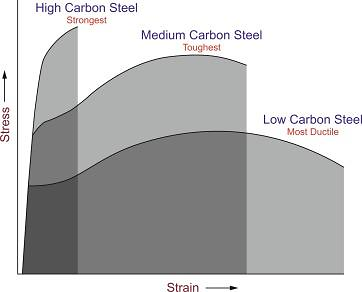

High-carbon steel is an alloy with a relatively high carbon content, ranging from 0.6% to 1.5%. It is used in applications requiring high hardness, such as blades, springs, and cutting tools. Due to its high carbon content, this alloy is brittle.

Are High-Carbon Steel Knives Prone to Breaking?

High-carbon steel is a brittle material due to its high carbon content. Carbon increases yield strength—high-carbon steel has a higher yield strength than other steels, meaning it is less likely to bend but more prone to breaking under excessive force.

Is High-Carbon Stainless Steel Suitable for Knives?

A good knife needs the following characteristics:

- High strength and hardness

- Sharpness

- Durability

- Rust resistance

High-carbon steel possesses these traits, but rust is a major issue. However, methods to prevent rust will be discussed in the following sections.

How to Clean High-Carbon Steel Knives

You can clean high-carbon steel knives with baking soda or soak them in vinegar.

How to Maintain High-Carbon Steel Knives

- Dry the knife immediately after use.

- Apply a layer of oil to enhance rust resistance.

How to Identify High-Carbon Steel Knives

- Scratch the knife and leave it overnight—if it rusts, it is likely high-carbon steel. Stainless steel or low-carbon steel knives remain shiny even after long-term use.

- Drop 1–2 drops of lemon juice on the steel and let it sit. If black spots form, it is most likely carbon steel.

Do High-Carbon Steel Knives Rust?

High-carbon steel knives rust easily if not properly maintained. Iron reacts with oxygen and moisture in the environment to form rust.

How to Prevent High-Carbon Steel Knives from Rusting

- Apply a layer of mineral oil, olive oil, or vegetable oil.

- Dry the knife after use.

- Store it in a dry place.

- Clean it regularly.

Advantages and Disadvantages of High-Carbon Steel Knives

Edge Retention and Sharpness

High-carbon steel knives are very hard and sharp due to their high carbon content (0.6%–1.00%). They can be re-sharpened easily, helping maintain a sharp edge.

However, their high hardness means they may chip if accidentally struck against hard surfaces. Rust is another issue if not properly maintained, which can severely affect performance.

Heat Treatment of High-Carbon Steel Knives

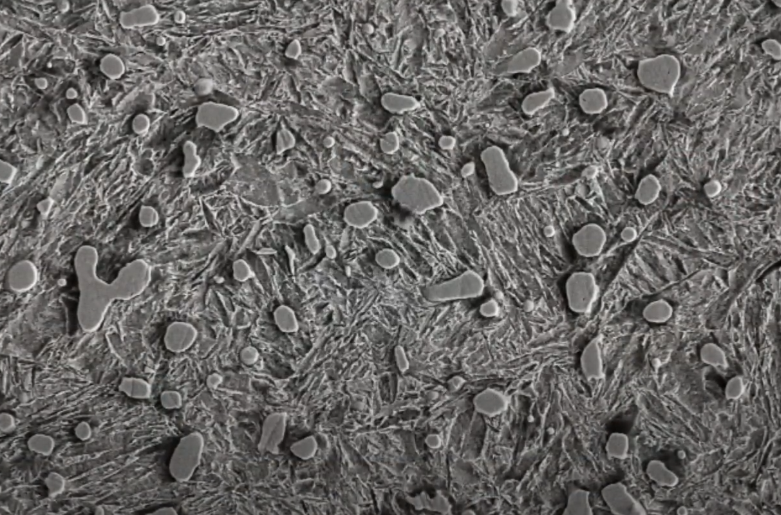

High-carbon steel is first heated to 780°C–850°C, then quenched in water or oil depending on hardness requirements. This treatment achieves a hardness of 55–62 HRC. Tempering is then performed to reduce brittleness and improve toughness.

Is 440C Steel Suitable for Knives?

440C is a stainless steel with good wear resistance and corrosion resistance due to its 16–18% chromium content. It is easy to heat-treat and offers good strength and durability—all essential traits for a good knife.

Is 440A Steel Suitable for Knives?

440A steel has high corrosion resistance but moderate strength in the 440 series. It is easy to machine and suitable for high-performance knives.

1095 High-Carbon Steel

1095 high-carbon steel has high hardness and wear resistance among steel grades. It is used to make weapons such as swords and knives.

1070 High-Carbon Steel

With a lower carbon content than 1095, 1070 balances durability, hardness, and edge retention.

1080 High-Carbon Steel

1080 is a popular grade due to its high strength, hardness, and toughness. Its carbon content is higher than 1070 but lower than 1095.

Types of High-Carbon Steel for Knives

Various steel grades are used to make knives for different purposes, each affecting performance:

Blades

High-carbon steel blades are used in chef’s knives, pocket knives, and multi-tools.

Knife Sets

These sets include high-carbon steel chef’s knives, valued for their hardness and wear resistance.

Kitchen Knives

Most kitchen blades are made of high-carbon steel for their excellent edge retention.

Boning Knives

High-carbon steel, with its flexibility and clean cutting ability, is ideal for boning knives.

Pocket Knives

Pocket knives are often made of high-carbon steel for sharpness.

Best High-Carbon Steel for Knives

1095 steel is considered the best for blades due to its perfect balance of durability and sharpness.

Best Steel for Kitchen Knives

VG-10, a Japanese steel grade, offers excellent edge retention, sharpness, and corrosion resistance—making it an exceptional choice for kitchen knives.

High-Carbon Steel Knives vs. Stainless Steel Knives

High-carbon steel knives excel in edge retention, while stainless steel knives offer superior corrosion resistance.

Comparisons with Other Steel Types

High-Carbon Steel vs. Low-Carbon Steel for Knives

Carbon is critical for hardness and machinability. High-carbon steel is harder and more wear-resistant but harder to machine than low-carbon steel.

High-Carbon Steel vs. AUS-8 Steel

High-carbon steel is sharp but prone to rust. AUS-8 (a Japanese grade) is rust-resistant and easy to maintain but requires frequent sharpening.

High-Carbon Steel vs. S30V Steel

S30V steel offers excellent rust resistance and toughness with lower maintenance needs.

High-Carbon Steel vs. VG-10 Steel

VG-10 contains chromium, giving it corrosion resistance and good sharpness.

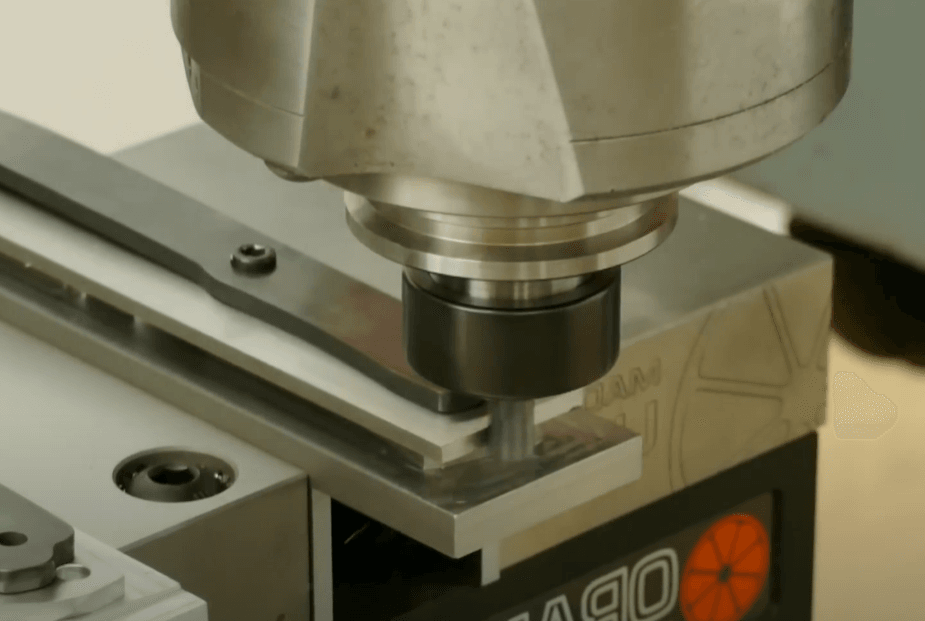

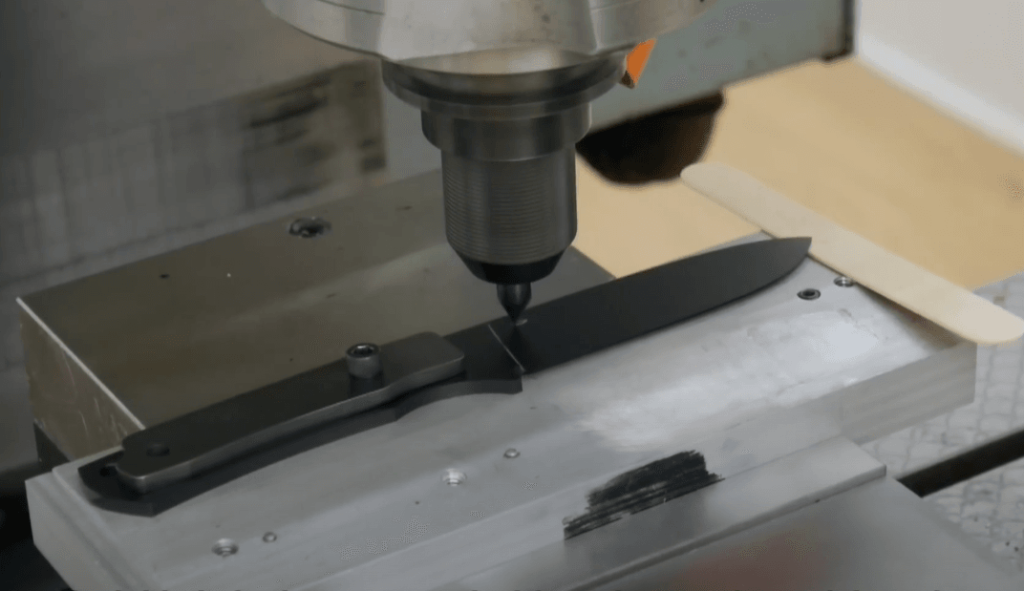

CNC Machining of High-Carbon Steel Knives

High-carbon steel is hard and brittle, making it difficult to machine. CNC machining is ideal for knife production due to its versatility, precision, and ability to cut with tight tolerances.

Patina Formation on High-Carbon Steel Knives

Patina is a thin layer that forms on high-carbon steel products over time. It develops when high-carbon knives are exposed to air and moisture.

For more information, please contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quotation.