Stock machining in CNC CAM is a method to optimize the material removal process. It uses smaller tools to machine areas that larger tools in previous operations cannot reach. This helps avoid tool wear, unnecessary material removal, and saves time. This article will further focus on the details of stock machining and guide you in formulating strategies and implementing best practices.

What is Stock Machining?

Stock machining is a technique in CNC machining that can effectively remove material from corners, notches, and other parts that large tools cannot reach.

What is Stock?

Stock refers to the remaining material that large tools cannot reach in previous CNC machining operations. It is the target material in stock machining and needs further processing.

Definition and Core Purpose of Stock Machining

It is a machining strategy that focuses on using smaller tools to remove the remaining material after previous CNC machining. The main purpose of this process is to optimize material removal, shorten machining time, and extend tool life.

What Happens When “Stock Machining” is Enabled?

When enabled, it allows the CNC machine to remove the remaining residual material and use smaller tools to machine areas such as corners or pockets, thereby improving surface finish and efficiency.

Key Terms in Stock Machining

Some commonly used terms in stock machining include:

- Remaining stock: The material left after previous machining operations with larger tools.

- Pencil pass: A type of stock machining that follows the edge of the remaining stock and creates a narrow, pencil-like path.

- Stock cleanup: The final operation to ensure all unnecessary material is removed.

Why Stock Machining is Important for Cycle Time and Tool Life

Stock machining allows larger tools to remove most of the material, and smaller tools to perform final finishing and optimization. Using this technique can reduce the need for multiple smaller tools, lower tool costs, shorten tool change time, and reduce the total cost per piece.

Material Removal Efficiency

Typically, before stock machining, the feed rate is high, which can cause tool overheating and premature failure. After that, by adjusting the cutting speed and feed rate, tool life can be extended, better surface finish can be obtained, and machining time can be shortened, thereby improving overall efficiency.

Tool Engagement and Wear

It strategically pauses the cutting tool for cooling and reduces tool wear, which is crucial for optimizing cycle time and extending tool life.

Surface Finish and Dimensional Accuracy

Stock machining improves surface quality and dimensional accuracy by ensuring a consistent finished blank.

Position of Stock Machining in the Toolpath Workflow

Stock machining is suitable in the toolpath workflow after roughing and semi-finishing but before final finishing to achieve higher precision, efficiency, and longer tool life.

Roughing → Semi-Finishing → Stock Machining → Finishing Sequence

The workflow of stock machining is as follows:

- Roughing: Larger tools remove most of the material and leave a large amount of stock.

- Semi-finishing: Smaller tools are used to finish the part, giving it a precise shape and removing more material.

- Stock machining: The same tool used for semi-finishing is employed, but with different parameters in corners and narrow areas.

- Finishing: Fine tools are used for the final processing to achieve the required surface finish and strict tolerances.

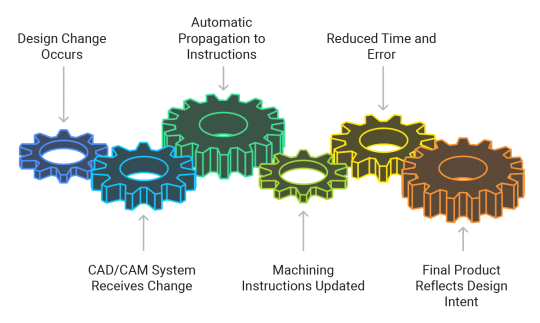

Generating Stock Models

The blank model represents the state of the workpiece at different machining stages. This is crucial for stock machining as it provides geometric information to identify the remaining material.

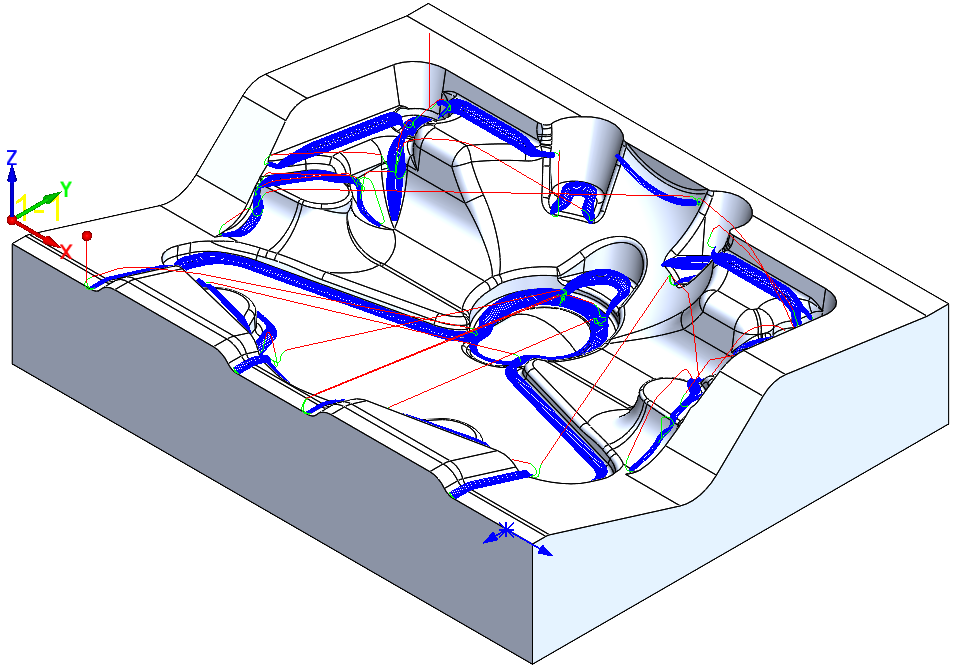

Stock Machining Strategies of Popular CAM Systems

Some commonly used CAM systems in stock machining include:

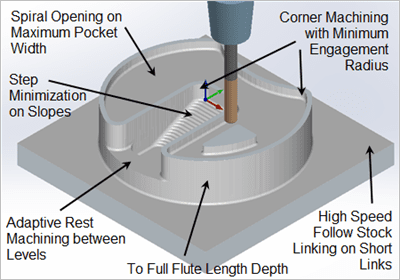

Fusion 360 Adaptive and Remaining Machining

It uses adaptive clearing and remaining machining to remove material. It has a default stock threshold, which is tool radius * 0.5.

Mastercam Dynamic Rest

It adopts a dynamic rest strategy for 3D pocket cleaning to identify and machine the remaining material from previous machining operations.

Siemens NX Cavity Mill

It uses a cavity milling strategy with a “rest” option to effectively remove the remaining stock.

HSMWorks Pencil Pass

It adopts the “pencil strategy” and is most suitable for cleaning corners and narrow areas that large tools cannot reach.

Quick Comparison Table

| Strategy | Ideal Parts | Cycle Time Gain (Approximate, %) |

|---|---|---|

| Fusion 360 Adaptive Clearing | Complex geometries with varying thicknesses | 20-50% |

| Mastercam | 3D cavity cleaning with inconsistent material removal | 15-30% |

| Siemens NX | Large, complex cavities with high material removal rates | 10-25% |

| HSMWorks | Thin and tight pockets with little remaining material | 5-15% |

Tool Selection and Cutting Parameters for Stock Machining

The focus of tool selection for stock machining is to minimize deflection and maximize material removal rate.

Small End Mills and Lollipop Mills

Small end mills are used for machining complex shapes and fine details, with diameters usually less than 1mm. Lollipop mills are most suitable for contouring and creating smooth surfaces in undercut areas.

Feed and Speed

Low feed rates and speeds are used to reduce cutting forces and prevent deflection.

Minimizing Deflection of Thin Walls

To minimize deflection, use support materials to prevent deflection, use low cutting forces, and use the Taguchi method to minimize deflection.

Applications of Stock Machining in Various Industries

Many industries adopt stock machining to save time, improve efficiency, and reduce tool wear and operating costs.

5-Axis Impeller Cleaning

5-axis machines can efficiently remove material from impeller blades and improve their accuracy, ensuring a smooth surface and optimal performance.

Tight Corners of Mold Cores

Stock machining can easily access narrow corners and complex geometries through 5-axis machining, and create high-quality molds with complex details.

Aluminum Electronic Enclosures

Stock machining can produce lightweight and durable aluminum enclosures with complex shapes and features for modern electronic products.

Stock Machining for Custom Projects

Stock machining is versatile and very suitable for manufacturing unique and precise custom parts, such as motorcycle triple clamps, which have requirements for both aesthetics and performance.

Common Pitfalls and Troubleshooting

There are some common pitfalls in stock machining that need troubleshooting.

Missed Material

After adjusting the roughing toolpath, stock machining may miss some material. To solve this problem, regenerate the stock machining toolpath after each modification.

Scallops

Excessively large stepover may cause obvious scallops on rounded corners. To solve this problem, reduce the stepover value in the machining parameters.

Tool Breakage in Deep Corners

Machining deep corners is difficult, and tools are prone to breakage. To solve this problem, air flow or spiral (ramp) entry strategies can be adopted to gradually remove material with lower cutting forces.

Conclusion

Stock machining can identify areas of remaining material on the workpiece after previous machining operations. It generates new toolpaths to remove this material, and usually uses smaller tools than the initial roughing operation.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quotation.