Investment casting, also known as lost-wax casting or precision casting, is a sophisticated casting process that produces complex metal components with tight tolerances and excellent surface finishes. It involves creating a wax pattern, encasing it in a ceramic mold, melting out the wax, and then pouring molten metal into the mold cavity.

This article details each process step, compares investment casting with other metal casting technologies, outlines material choices, and provides criteria for selecting a reliable investment casting foundry. Before investing in tooling for this process, read on to ensure it is the best fit for your product.

Understanding the Investment Casting Process

The investment casting process transforms wax patterns into high-quality metal parts through a series of controlled steps. It can deliver near-net-shape complex designs with minimal post-processing. Its accuracy and repeatability stem from the wax pattern’s ability to replicate complex geometries and the ceramic mold’s smooth surface, making it ideal for parts like turbine blades or orthopedic implants.

6 Steps of the Investment Casting Process

Creating the Wax Pattern

Wax patterns are created via injection molding to replicate the final part’s geometry, capturing details such as internal channels or sharp corners. A blend of paraffin and microcrystalline wax maintains the pattern’s shape without distortion at an injection temperature of 70-90°C, ensuring fidelity to the mold cavity.

Patterns for mass production are produced using precision molds with CNC-machined tolerances of ±0.01 mm, ensuring dimensional accuracy of the parts. Engineers must design patterns with a 1-2.5% shrinkage allowance to account for wax and metal cooling, and use simulation tools like Moldflow for optimization.

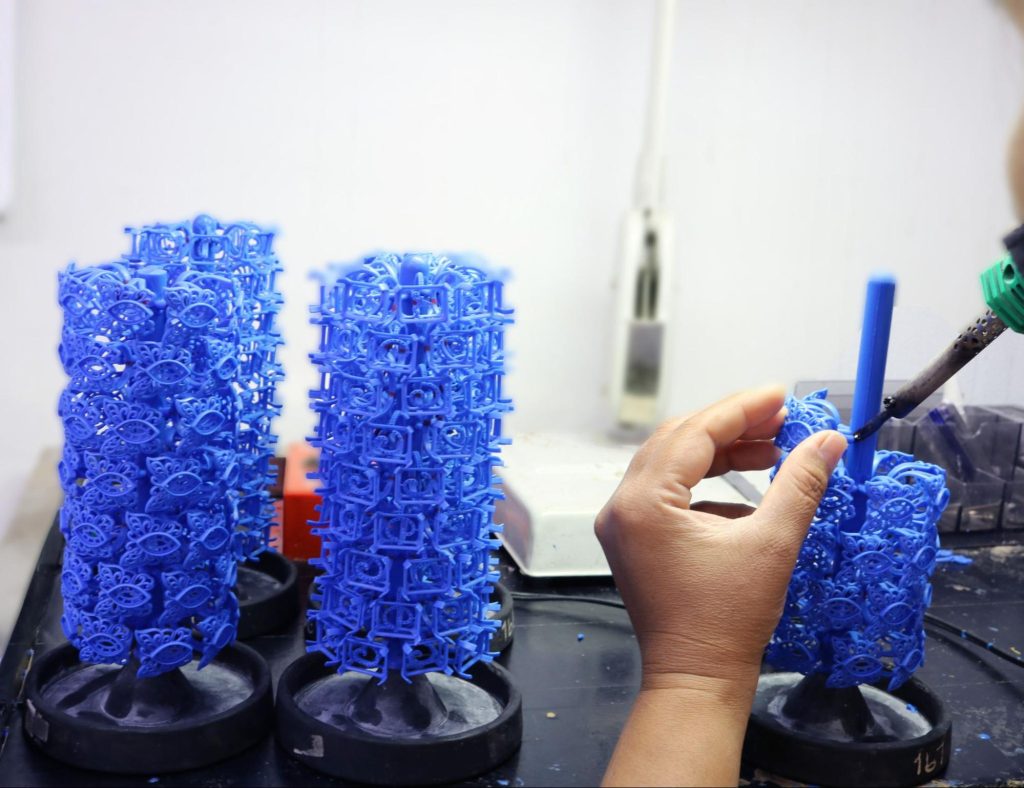

Assembling Wax Patterns into a Tree

Multiple wax patterns are bonded to a central wax sprue manually or robotically using heated tools or adhesive wax, forming a tree-like structure that allows 10-50 parts to be cast simultaneously. While patterns are usually molded individually, complex designs may incorporate tree elements during injection molding to reduce the number of assembly steps. Proper alignment, verified by vision systems, prevents casting defects such as incomplete filling.

The sprue and runner system is optimized for manufacturing precision using CAM software, ensuring uniform metal flow and minimizing turbulence. This design reduces per-part costs by 20-30% for medium volumes (100-5,000 parts) by enabling batch casting and maximizing material utilization. Automated robotic assembly improves consistency, reducing misalignment risks by 15-20%.

Applying the Ceramic Shell Coating

The wax tree is dipped into a ceramic slurry containing colloidal silica as a binder, ceramic powder (e.g., zirconia, fused silica), and heat-stability additives. During 6-8 dipping and drying cycles, fine refractory sand (e.g., alumina, aluminosilicate) is applied as a stucco coating, forming a 5-10 mm thick shell.

Each layer dries for 4-12 hours under controlled humidity to prevent cracking. The shell’s strength (up to 10 MPa) resists thermal stress from molten metal (1,400–1,600°C) and cooling, as well as pressure from gravity or vacuum-assisted pouring (0.1–0.5 MPa). This durability is crucial for maintaining cavity integrity across all mold geometries. Engineers monitor slurry composition, pH, temperature, and viscosity to prevent voids and ensure mold quality, which is vital for part precision.

Dewaxing and Preheating

Wax is melted out of the ceramic shell in an autoclave at 150-200°C and 7-10 bar steam pressure, leaving a hollow ceramic mold cavity. This dewaxing step is the core of lost-wax casting, ensuring the cavity is clean and free of residues for accurate metal replication. The mold is then preheated to 540–1,090°C to prepare for the molten metal.

Preheating minimizes thermal shock, which could crack the shell due to rapid temperature gradients. It also prevents metal from solidifying prematurely on the mold walls, ensuring complete filling of complex details. Additionally, preheating reduces porosity by 15-20% by maintaining uniform mold temperature, limiting gas entrapment and shrinkage voids, thus improving part density and structural integrity.

Pouring Molten Metal

Molten metal (e.g., 17-4 PH stainless steel, Ti-6Al-4V) at 1,400–1,600°C is poured into the mold using gravity, vacuum-assisted, or centrifugal methods. Vacuum casting, often used for titanium, minimizes oxidation, ensuring defect-free surfaces. Pouring speed (0.5–2 kg/s) is critical to prevent cold shuts and requires precise control via automated systems.

Cooling, Decoring, and Finishing

After solidification (10-60 minutes, depending on the alloy), the ceramic shell is removed using vibration or high-pressure water jets (100-200 bar). Parts are cut from the sprue and undergo grinding, sandblasting, or polishing to achieve a 32–63 μin Ra surface finish. Secondary machining may be required for ultra-tight tolerances (±0.001 inches), typically achieved via precision CNC machining.

Investment Casting vs. Other Casting Methods

Investment casting stands out among metal casting technologies for its precision and versatility. The table below compares it with other common methods, highlighting differences in surface finish, accuracy, complexity, material options, tooling costs, and volume suitability.

| Casting Method | Surface Finish | Dimensional Accuracy | Part Complexity Capability | Material Options | Mold Cost | Volume Suitability |

|---|---|---|---|---|---|---|

| Investment Casting | Excellent (32–63 μin Ra) | ±0.005 inches–0.015 inches | Very high | Wide (steel, high-temperature alloys) | Medium | 500-5,000 parts |

| Die Casting | Good (60–120 μin Ra) | ±0.004 inches–0.010 inches | High | Limited (mainly Al, Zn, Mg) | High | 5,000–10,000+ parts |

| Sand Casting | Fair (125–500 μin Ra) | ±0.030 inches–0.125 inches | Moderate | Wide | Low | 1–1,000 parts |

| Permanent Mold Casting | Good (63–125 μin Ra) | ±0.010 inches–0.030 inches | Moderate | Limited | Medium-High | 1,000–10,000 parts |

- Comparison of investment casting with other casting methods.

The “medium” mold cost for investment casting reflects the initial investment in wax pattern tooling and ceramic coating facilities, balanced by reduced machining requirements. Die casting’s “limited” material selection is due to process constraints, unlike investment casting’s broad range.

Advantages of Investment Casting

Investment casting offers several unique advantages that make it the “go-to” process for complex applications with tight tolerances:

- High Dimensional Accuracy: Achieves tolerances of ±0.003″–0.005″, capturing fine details and reducing machining needs.

- Excellent Surface Finish: Delivers 32–63 μin Ra, minimizing post-processing for both aesthetic and functional parts.

- Material Versatility: Supports the use of ferrous metals, stainless steel, aluminum, Inconel, and other alloys, meeting diverse performance needs.

- Complex Geometries: Enables thin walls (0.040″), undercuts, and internal channels, allowing part consolidation.

- Cost-Effective for Medium Volumes: Economical for runs of 100-5,000 parts, balancing tooling and per-part costs.

Industry Applications and Use Cases of Investment Casting

Investment casting provides high-performance metal components for various industries. This method excels in applications such as turbine blades, medical devices, and industrial machinery where precision and surface quality are critical. Here are key industries relying on investment casting for their tight tolerances, complex geometries, and ability to utilize high-performance materials.

Aerospace

Investment casting is vital in aerospace for manufacturing high-precision components. Inconel 718 turbine blades with internal cooling channels are used to maintain jet engine efficiency. Titanium brackets are also cast to reduce weight without compromising structural strength. Aluminum castings are often used in pressure vessels.

Automotive

In the automotive industry, investment casting produces durable stainless steel turbocharger housings that support efficient engine performance, enabling smaller engines with sufficient power output to improve fuel efficiency and reduce CO₂ emissions. It also allows for precise transmission gears, enhancing the vehicle’s overall efficiency.

Medical

Medical device applications of investment casting include cobalt-chromium alloy scalpels with biocompatible edges that simplify sterilization. Titanium hip implants are also produced using investment casting, ensuring a precise fit and long-lasting performance.

Industrial Machinery

Investment casting supports the industrial machinery sector by producing stainless steel pump impellers that improve hydraulic efficiency. It is also used to manufacture corrosion-resistant valve bodies with complex internal structures.

Defense

In the defense sector, investment casting is relied upon to produce weapon components made from high-strength alloys, ensuring reliability and durability in critical applications.

Investment Casting Innovations and Future Trends

As engineering demands become more complex, investment casting is evolving to meet the challenges. From 3D-printed patterns to smart foundries and sustainable practices, the industry is adopting new technologies to enhance efficiency, precision, and environmental responsibility. Here are the factors shaping the future of investment casting:

Integrating 3D Printing for Rapid Prototyping and Pattern Creation

Additive manufacturing has revolutionized pattern creation by enabling rapid prototyping and direct production of complex wax patterns. This technology reduces lead times, eliminates pattern tooling for small-batch runs, and allows for mass customization of wax patterns with specific design variations previously unattainable with traditional methods. Learn how 3D printing services can accelerate the wax pattern creation step.

Advances in Ceramic Shell Materials for Improved Performance

New ceramic formulations offer enhanced thermal shock resistance, greater dimensional stability, and superior surface finish transfer to castings. These advancements expand the range of pourable alloys and improve overall process reliability.

Automation and Digitization in the Casting Process

Smart foundry technologies combine sensors, data analytics, and automated processing systems to improve process consistency and reduce labor costs. Digital twin technology enables virtual process optimization before physical production begins.

Sustainability Initiatives and Waste Reduction Strategies

Environmental awareness has driven innovations in ceramic shell recycling, energy-efficient melting systems, and emission-reducing processes. These initiatives lower environmental impact while reducing operational costs.

Choosing the Right Investment Casting Manufacturer

Selecting the right investment casting service manufacturing partner is crucial for project success. Several key factors should guide your selection process:

- Experience and Certifications: Look for suppliers with AS9100 (aerospace) or ISO 13485 (medical) certifications and industry-specific expertise.

- Material Capabilities: Confirm proficiency with your required alloy (e.g., titanium, Inconel).

- Quality Control: Ensure the supplier uses statistical process control and has part inspection capabilities such as X-ray machines and a full metallurgical testing lab.

- Lead Time and Capacity: Verify that the potential supplier can meet your project timeline and volume requirements (100-5,000 parts).

- Technical Support: Prioritize partners offering design for manufacturability (DFM) and 3D-printed pattern prototyping.

Is Investment Casting Suitable for Your Application?

Investment casting offers precision, high surface quality, and the ability to manufacture complex metal parts from a variety of materials for various industries. Its typical tolerances of approximately ±0.003″ and surface finishes ranging from 32-63 μin Ra make it well-suited for production runs of 500-5,000 parts.

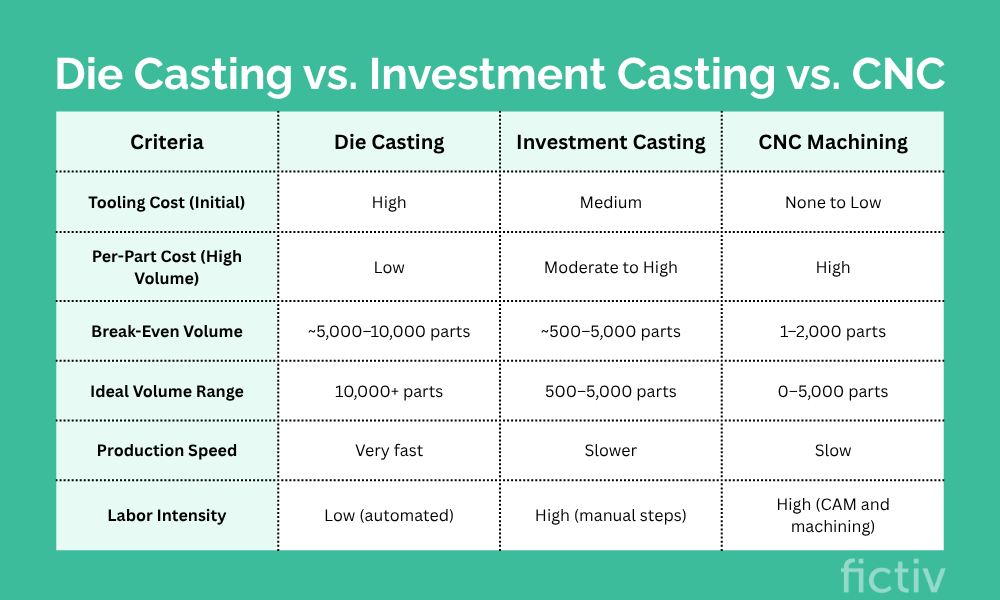

While investment casting provides many advantages, it is important to consider the trade-offs. If your project requires higher production volumes and faster production cycles, die casting may be more suitable. For small batches or early prototypes, CNC machining can offer flexibility and speed without tooling costs.

If your design requires precision metal components with complex features, choosing the right manufacturing process is key. Debaolong Seiko‘s network of manufacturing partners and technical experts in manufacturing and supply chains can help guide you to the best solution for your project.