Feeling a bit anxious about an upcoming medical procedure? That’s understandable, but you don’t need to worry about whether the instruments are sterile and free of microorganisms. Over 150 years ago, doctors began to recognize the importance of sterilizing equipment, but it wasn’t until 1879 that French microbiologist Charles Chamberland invented a device to deliver sterilized instruments: the autoclave.

How Autoclaves Work

An autoclave operates much like a pressure cooker—used by some to pickle cucumbers and eggs. Instruments are first placed in a sealed chamber, then a pump expels all air from the interior. The temperature is raised to at least 250°F (121°C), and pressurized steam is applied for 30 to 60 minutes.

Other sterilization methods exist, including dry heat, radiation and ultraviolet light, ethylene oxide gas, and vaporized hydrogen peroxide, but this article focuses on autoclaving. More importantly, it describes materials and surface treatments that can withstand the heat and moisture of this common sterilization method.

What Works (and What Doesn’t) in Autoclaves

Let’s start with materials that are definitely not suitable for autoclaving. Fortunately, this list is short:

- Polyethylene (PE) and its low- and high-density variants (LDPE and HDPE—though the latter comes close)

- Polymethyl methacrylate (PMMA, better known as acrylic)

- Polystyrene (PS)

- Polyvinyl chloride (PVC)

Now, here are the materials that can withstand autoclaving:

- Polyamide (Nylon or PA): A common thermoplastic known for its strength and wear resistance.

- Polypropylene (PP): A low-cost polymer capable of withstanding autoclave temperatures.

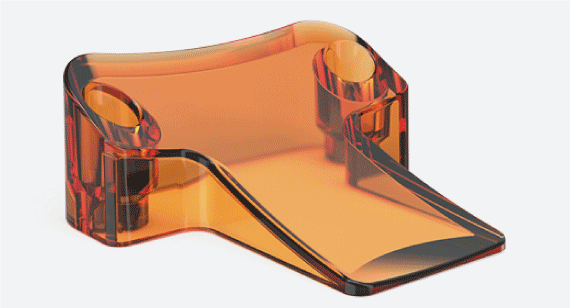

- Polycarbonate (PC): An optically transparent (and more expensive) alternative to acrylic—think bulletproof glass.

- Polyoxymethylene (POM): Also called acetal or Delrin, an engineering-grade thermoplastic with a low friction coefficient, high rigidity, wear resistance, and good dimensional stability.

- Polytetrafluoroethylene (PTFE): You may know it by the brand name Teflon, a fluoropolymer with strength and extreme chemical resistance across a wide temperature range.

- Polyetheretherketone (PEEK): An organic thermoplastic that has become a staple in the medical field since its invention in 1978. It’s used in everything from medical implants to ultra-high-vacuum and gas chromatography components.

- Silicone and its variant LSR (Liquid Silicone Rubber): Another versatile material, ideal for parts requiring flexibility, biocompatibility, and resistance to chemicals and bacterial growth. Yes, it is autoclave-safe.

- Polyphenylene sulfide (PPS), polysulfone (PSU), and polyethersulfone (PES): These and other thermoplastics are easy to machine, injection mold, or 3D print and can withstand autoclaving.

Autoclave-Safe Metals

While polymers are excellent for various medical parts, metals also play a key role. The four most common alloys in the medical market are 304 and 316 stainless steel, along with their low-carbon counterparts 304L and 316L. They are widely used in medical devices, surgical tools like scalpels and clamps, wheelchairs, wires, and waste containers.

316L is the most popular for internal components, including bone screws, fixation plates, and other implants. For orthopedic devices requiring higher strength and fatigue resistance, cobalt-chromium (CoCr) or Ti-6Al-4V titanium are often preferred.

For each of these metals, passivation with nitric or citric acid after manufacturing is critical. This removes any free iron from the surface and forms a protective oxide layer, significantly enhancing corrosion resistance.

Aluminum is also a candidate for autoclave-safe medical parts, provided it first undergoes medical-grade Type II (sulfuric acid) or Type III (hard-coat) anodizing for conversion coating. The same applies to many steels—such as 1018 low-carbon steel or the tougher 4140—but their corrosion-prone surfaces must be protected with hard chrome or bright nickel plating.

The medical industry is demanding, with strict specifications and quality requirements. Thus, it’s crucial to investigate the type of sterilization needed to make parts safe for their intended use and identify which materials meet those criteria.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.