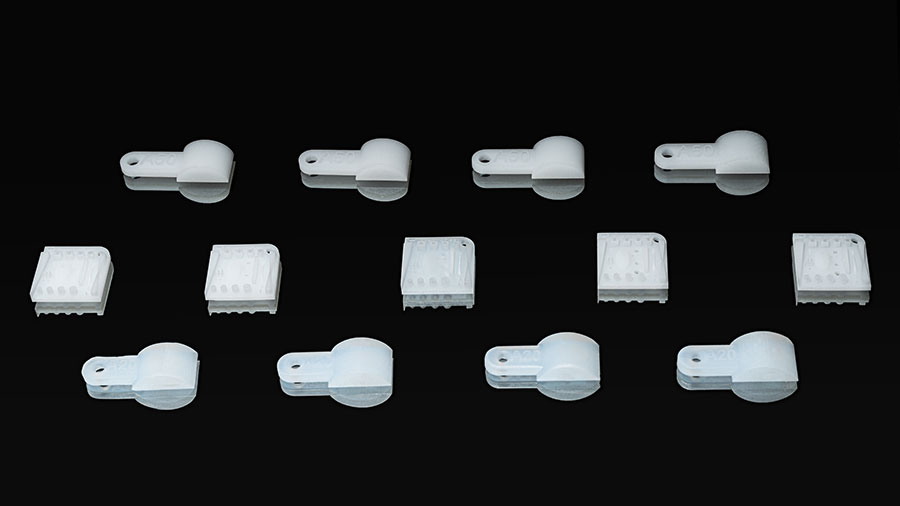

Manufacturing molded parts using liquid silicone rubber (LSR) has been around for a long time, but 3D printing with TruSil silicone—a new process—might be exactly what you need when developing silicone components. Imagine iterating on parts quickly, reliably, and accurately using 3D printing. You can refine design elements without incurring multiple upfront tooling costs, saving both development time and production expenses.

How It Works

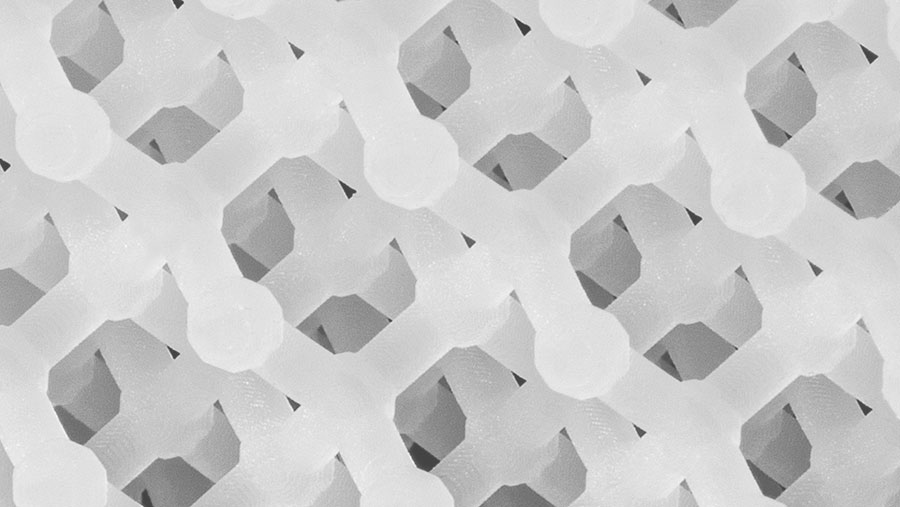

LSR is a popular elastomer that has been a staple in injection molding for decades. Now, silicone is available in a liquid resin form, enabling 3D printing via stereolithography (SLA). SLA is a commonly used printing technology because it creates smooth parts with no visible layers. Essentially, a laser targets a vat of silicone resin, building the part layer by layer. With each pass, the part structure is lowered slightly into the resin tank, and the part is eventually completed. Support structures are then removed, and the part undergoes a UV curing cycle to solidify the material.

The table below outlines the properties of 3D-printed silicone compared to other manufacturing processes and similar materials:

| Manufacturing Technology | Material | Color | Hardness (Shore A) | Maximum Part Size | Surface Finish | Cost | Applications |

|---|---|---|---|---|---|---|---|

| SLA | Silicone | Semi-transparent white, black | 20 to 60A | 4.7 in x 2.8 in x 3.9 in (119.4 mm x 71.1 mm x 99.1 mm) | Smooth texture, no visible layers | $$$ | Prototypes of molded silicone parts, seals, gaskets, wearables, buttons |

| PolyJet | Photopolymer | Black, transparent/translucent, white | 30A to 95A | 19.3 in x 15.4 in x 7.9 in (490.2 mm x 391.2 mm x 200.7 mm) | Smooth texture | $$ | Overmolding prototypes |

| SLS | Thermoplastic Polyurethane (TPU) | White | 70A | 10.6 in x 12.6 in x 16 in (269.2 mm x 320.0 mm x 406.4 mm) | Rougher, sugar-cube-like texture | $ | Fixtures, hoses, applications requiring dynamic load resistance |

| Injection Molding | Liquid Silicone Rubber (LSR) | White, optically clear, multiple colors | 30A to 70A | 12 in x 8 in x 4 in (304.8 mm x 203.2 mm x 101.6 mm) | Smooth texture, multiple options | $$$$ | High-volume prototyping, pilot runs, end-use production parts |

Advantages of 3D-Printed Silicone

Fundamentally, silicone printing produces parts that closely resemble those made with silicone molding. It offers a wide range of Shore A hardness, from 20A to 60A (comparable to rubber bands to car tire treads), while molded silicone typically ranges from 30A to 70A. Like other SLA materials, silicone printing delivers excellent detail and resolution.

Other advantages include resistance to:

- Acidic or alkaline environments

- Deformation

- High temperatures

- Moisture

- Tearing

- Ultraviolet (UV) light

- Wear

Silicone is highly elastic and provides waterproof sealing. Additionally, if you need medical components, silicone meets the mark—this specific silicone has passed key biocompatibility tests, including ISO DIN EN 10993-05 (in vitro cytotoxicity testing) and ISO DIN EN 10993-10 (irritation and skin sensitization testing).

Limitations of Silicone Printing

Of course, silicone printing has considerations to keep in mind. Currently, the size of printable parts is moderate: parts cannot exceed 4.7 in x 2.8 in x 3.9 in (119.38 mm x 71.12 mm x 99.06 mm). Additionally, printing is done overseas, which may raise concerns if you require ITAR or other import/export certifications.

Color options are limited to semi-transparent white (for all hardness levels) or black (for 60A). Thus, if you’re seeking colored parts, molding is the better choice. That said, if your goal is simply to test design integrity, color may be irrelevant.

Another consideration relates to transitioning from printing to molding. If you plan to use printing as a prototyping step and move to molded parts for on-demand manufacturing volumes, ensure your design is moldable before incorporating special features.

Last but not least is cost. In some ways, this is neither strictly an advantage nor a limitation. While silicone printing is not cheap compared to other printing options and materials, it is more affordable than paying for molds—and iterating with multiple molds. Thus, while silicone printing isn’t inexpensive, it is a solid choice for saving money during prototyping and potentially throughout a part’s lifecycle.

For more information, please contact Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.