What is Powder Coating and How Does It Work?

Powder coating is an efficient surface treatment and finishing method, valued across various industries for its durability and performance. Unlike traditional liquid paints that rely on wet application, powder coating involves dry powder that is electrostatically charged and cured with heat. This process results in a tough, high-quality finish that resists corrosion, chipping, and fading, making it an excellent alternative to conventional coatings.

Compared to other options, powder coating is often the best choice due to its superior finish, durability, and environmental friendliness. It is also more efficient, reducing waste while avoiding the use of harmful solvents. Powder coating is an excellent option for CNC machined, sheet metal, or die-cast parts.

Powder coating is a cost-effective method applicable to a variety of materials beyond metals, including plastics, making it beneficial for industries such as automotive, aerospace, construction, and consumer goods. Additionally, powder coatings are available in a wide range of colors, and finishes can be customized to meet aesthetic requirements.

Powder Coating Process

Surface Preparation

Proper surface preparation is crucial for the successful application of powder coating. Before applying the powder, the substrate must be thoroughly cleaned to remove dirt, grease, and other contaminants. This step typically involves washing and degreasing to eliminate oils or residues, which is essential for ensuring proper adhesion of the powder.

The substrate may also undergo surface finishing to create a rough profile, enhancing powder coating adhesion. This can include shot blasting, sandblasting, or abrasive blasting, which increase surface area and strengthen the mechanical bond between the coating and the substrate, resulting in a more robust and durable finish. However, such surface treatment is not always necessary, as chemical cleaning processes and initial baking are often sufficient to remove debris.

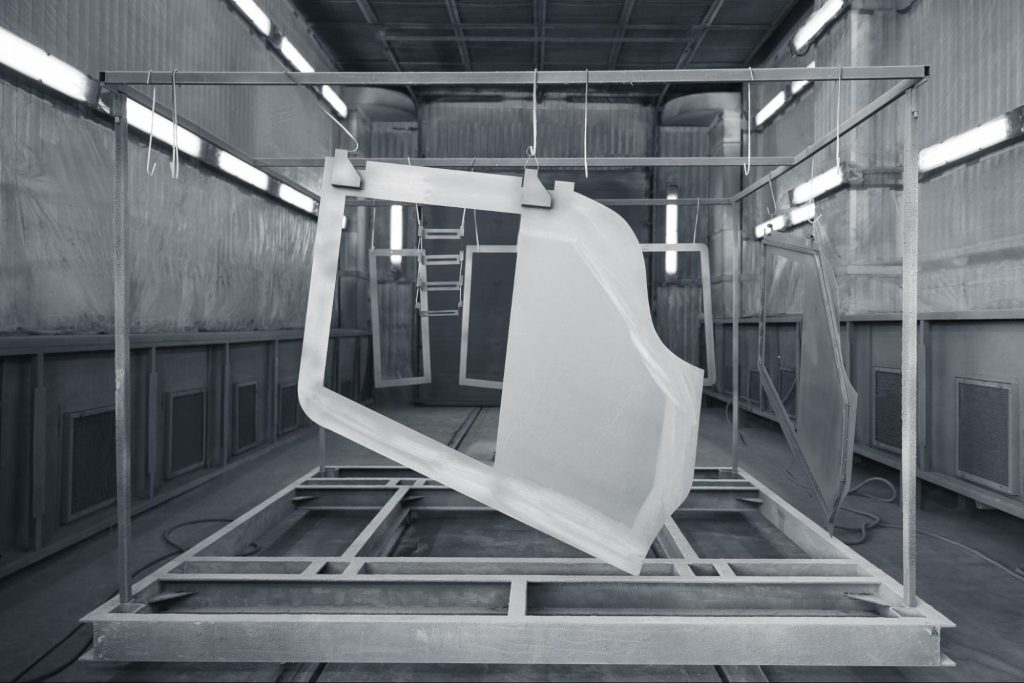

Application Process

The two primary methods for applying powder coating are Electrostatic Spray Deposition (ESD) and fluidized bed coating.

- Electrostatic Spray Deposition (ESD): The most common method, where charged powder particles are sprayed onto a grounded metal surface. This ensures uniform coverage and strong adhesion. However, factors such as voltage settings, film thickness, and part geometry must be carefully controlled. Automatic voltage adjustment helps maintain consistent finishes, while spray techniques may need modification for complex shapes to ensure proper coverage.

- Fluidized Bed Coating: Used for batch processes, preheated parts are dipped into a fluidized bed of powder. Upon contact with the hot surface, the powder melts, forming a thick, uniform coating. This method is particularly effective for applications requiring high impact resistance, as it can produce coatings of 10+ mils, enhancing durability.

Curing Process

The curing process transforms the applied powder into a hard, durable surface, typically via thermal curing. Coated parts are heated in an oven, with standard curing temperatures ranging from 325–450 °F (163–232 °C) and curing times between 10–30 minutes, depending on the material and coating thickness. As the powder melts, it forms a smooth protective film that bonds permanently to the substrate.

Alternatively, UV-curable powder coatings require lower temperatures, making them suitable for substrates that cannot withstand high heat. In this process, the powder is applied and then exposed to ultraviolet light, triggering a rapid chemical curing reaction. While not suitable for all applications, UV curing significantly reduces processing time while still providing long-lasting protection similar to thermal curing.

Advantages of Powder Coating

- Durability: Powder-coated surfaces are highly resistant to scratches, chipping, corrosion, and chemicals. They also meet strict performance standards, such as pencil hardness (ASTM D3363) and salt spray resistance (ASTM B117), ensuring long-term protection.

- Versatility: Powder coatings offer exceptional flexibility in color, texture, and gloss. Custom finishes can be achieved to meet diverse design needs, including matte, satin, glossy, metallic, and textured coatings.

- Environmental Friendliness: Powder coating is a sustainable choice, as it contains no solvents, generates minimal hazardous waste, and has a high transfer efficiency of nearly 98% due to recyclable overspray. This reduces material waste and improves cost efficiency, as less product is needed compared to liquid paints. Additionally, its durability lowers long-term maintenance costs.

- Dual Purpose: Beyond aesthetics, powder coating is widely used in industrial applications. It can be customized to match Pantone and Reichs-Ausschuss für Lieferbedingungen (RAL) color standards, including metallic, textured, and clear finishes.

Limitations and Challenges of Powder Coating

Despite its advantages, powder coating has some drawbacks:

- Coating Thickness Control: The ideal thickness is 2–6 mils (0.002–0.006 inches). Excessive coating can cause an “orange peel” effect—a rough, dimpled texture. High humidity, extreme temperatures, or equipment failure may also contribute to this issue.

- Material Restrictions: Some polymers and composites cannot withstand the high curing temperatures required for powder coating, necessitating alternative coating methods. Additionally, certain metals require pre-treatment to improve adhesion and coating performance.

- Chipping in High-Impact Areas: Severe impacts can cause the finish to chip unless the coating formula is specifically designed for high impact resistance. However, this issue can be addressed by selecting the right powder coating formula for the intended application.

To overcome these challenges, careful consideration of substrate material, application method, and end use is essential. Despite these limitations, powder coating remains a highly versatile and beneficial surface treatment solution across industries.

Industrial Applications of Powder Coating

Powder coating’s versatility and beneficial properties make it essential in numerous industries:

- Medical Technology: Antimicrobial powder coatings are used on medical devices and hospital equipment to reduce the spread of infectious microorganisms.

- Climate Technology: Provides corrosion protection to enhance durability and efficiency of heavy equipment such as solar panels, wind turbines, and energy storage systems.

- Automotive: Widely used on rims, engine parts, chassis, and nearly all other automotive components exposed to high temperatures and chemicals.

- Aerospace: Applied to aircraft frames and interiors, which require high strength-to-weight ratios to withstand harsh conditions, ensuring durable finishes.

- Industrial Machinery: Used with armor-grade protection for equipment and enclosures that corrode over time.

- Consumer Goods: Aesthetic and durable finishes for bicycles, fitness equipment, and electronics.

- Construction: Erosion protection and enhanced design for railings and window frames.

- Retail Displays and Advertising: Signage, display racks, and store fixtures that withstand harsh weather with unmatched strength and aesthetics.

Comparison of Powder Coating with Other Common Surface Treatments

The choice of coating depends on desired results and materials. Below are some common alternatives to powder coating (non-exhaustive):

| Finishing Process | Advantages | Disadvantages |

|---|---|---|

| Powder Coating | – Durable and resistant to corrosion, chemicals, and UV radiation – Environmentally friendly (low VOCs) – Provides thick, uniform coatings | – Requires high curing temperatures – Difficult to repair or touch up – Increases part thickness |

| Anodizing | – Excellent corrosion resistance – Increases surface hardness – Provides electrical insulation – Can be dyed for aesthetics | – Limited to aluminum and a few other metals – Poor coverage of welds or defects – Brittle and prone to chipping under impact |

| Chemical Conversion Coating | – Thin coating improves corrosion resistance and paint adhesion – Low cost and easy to apply – Can conduct electricity (depending on type) | – Limited color versatility – Offers minimal standalone protection (often used as a base for paint) – Poor wear resistance – May contain hazardous chemicals |

| Liquid Coating | – Wide range of colors and finishes – Applicable to various substrates – Easy to repair and touch up | – Long drying times – Requires solvents for application – Less durable than powder coating or anodizing – Higher VOC emissions (environmental concerns) |

Enhance Your Product Quality with Debaolong Seiko’s Powder Coating Solutions

Powder coating is not only cost-effective and visually appealing but also environmentally friendly. Many industries prefer it as a surface treatment option because it provides a durable finish that meets mechanical and aesthetic requirements. By using powder coating, companies can significantly improve operational efficiency.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.