Injection molding is renowned for rapidly producing parts with consistent precision, making it one of the most popular methods for manufacturing high-quality plastic components. This manufacturing process creates parts by forcing molten plastic into a mold under high pressure, where it cools and solidifies into the desired shape. It is used across industries to efficiently produce complex, durable products at a relatively low unit cost.

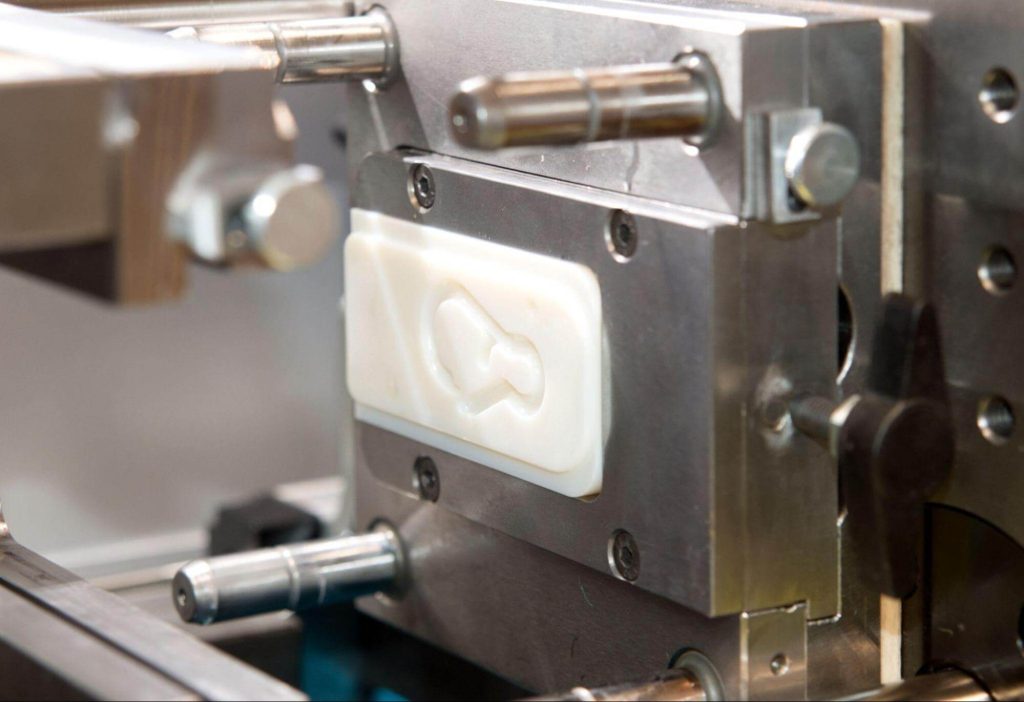

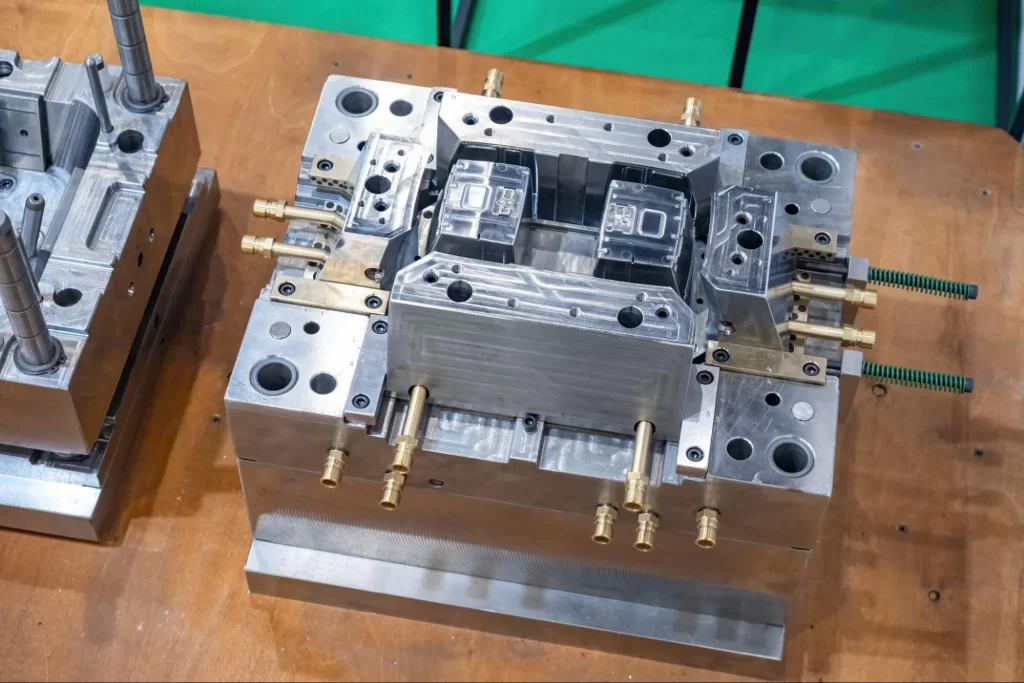

Injection molds are critical to the entire process. Also known as “tools,” these molds are meticulously designed to withstand high temperatures and pressures for hundreds of thousands of cycles. Many factors—including mold type and material—influence overall cost, production volume, and durability.

The Critical Role of Molds in Injection Molding

Effective mold design and selection significantly impact efficiency, cost, and overall product quality. A well-structured mold facilitates smooth production and high-quality output, while mold failure or inefficiency can lead to increased downtime, defects, and significant financial losses.

In industries where precision and speed are paramount, robust tooling is essential for successful molding operations. With proper molding parameters, a carefully designed tool can rapidly and repeatedly produce complex features with tolerances as tight as +0.002 inches (0.05 mm).

Types of Injection Molds and Key Components

In injection molding, the mold itself is the most important component, as it defines the shape, quality, and efficiency of part production. Factors like production volume, part complexity, and cost considerations determine the type of mold used. Beyond selecting the right mold type, understanding key mold components is critical for optimizing performance, ensuring proper material flow, and achieving consistent part quality.

Types of Injection Molds

- Single-Cavity Molds

Single-cavity molds produce one part per cycle. This type is ideal for low-volume production, prototyping, or cases where the cost of multiple cavities outweighs the benefits. While slower than other mold types, single-cavity molds have lower complexity and manufacturing costs, making them suitable for small projects or highly specialized parts. - Multi-Cavity Molds

Multi-cavity molds contain multiple cavities, allowing simultaneous production of multiple identical parts in one cycle. This is efficient for high-volume production, as it significantly reduces unit costs and increases output. However, maintaining consistent quality across all cavities is challenging. Thus, precision in mold design and machining is critical to ensuring uniform finished part quality. - Family Molds

Family molds are designed with multiple cavities to produce different parts in a single cycle. This is useful for manufacturing parts that will be assembled together. However, balancing material flow and ensuring uniform part quality can be more challenging, as different cavities may require varying flow rates and cooling times. - Stacked Molds

Stacked molds feature multiple layers or stacks, increasing the number of parts produced without requiring a larger machine. This design improves production efficiency by maximizing output per machine footprint, making it ideal for large-scale manufacturing where reducing cycle times and increasing volume are critical. - Rapid or “Soft” Tooling

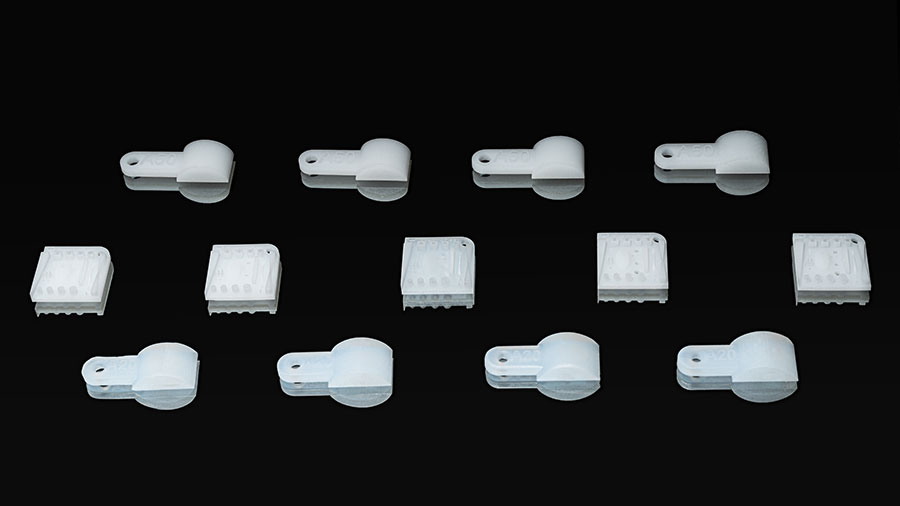

For prototyping or low-volume production, rapid molds made from 3D-printed polymers or softer metals (e.g., aluminum) can quickly produce and validate design concepts. While optional, using a “prototype tool” (soft tooling) is often recommended before investing in full-production tooling.

Key Injection Mold Components

The following components influence mold functionality and efficiency:

- Injection Mold Halves (Core and Cavity)

- Core: Convex-shaped, forming the part’s internal geometry (e.g., holes, grooves, hollow areas).

- Cavity: Concave-shaped, defining the part’s external features (e.g., ribs, bosses, logos, decorative textures).

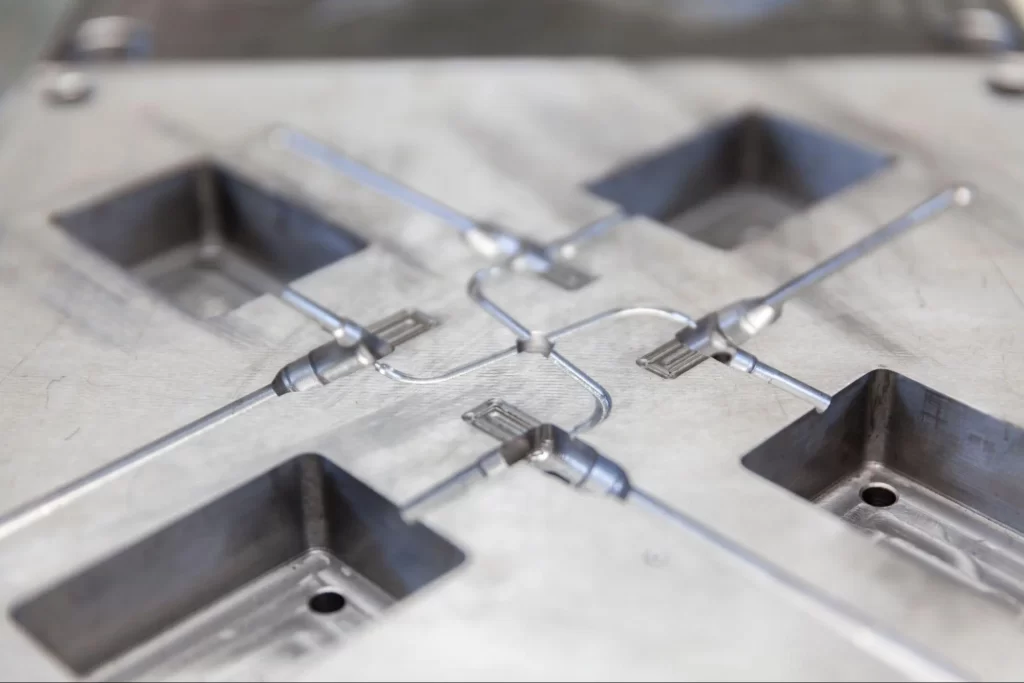

- Runners and Gates

Runners are channels that guide molten plastic from the injection nozzle to the mold cavities, while gates are the entry points into the cavities. The design and placement of runners and gates are critical for ensuring proper material flow, minimizing waste, and avoiding defects like short shots or uneven filling. - Cooling System

Efficient cooling reduces cycle times and prevents part defects (e.g., warping, shrinkage). Cooling systems typically consist of channels through which coolant (e.g., oil or water) flows. Channels are strategically placed throughout the mold to ensure uniform temperature distribution. Proper cooling system design significantly impacts part quality and production speed. - Ejector System

After the part cools and solidifies, the ejector system removes it from the mold. This system usually includes ejector pins or plates that push the part out without damage. The timing and force of the ejection process must be carefully controlled to avoid part deformation and minimize scarring.

The design of mold types and their components plays a vital role in determining the production speed, efficiency, quality, and cost-effectiveness of the injection molding process.

Managing Costs Without Compromising Tool Quality

Multiple factors affect mold costs, including mold material, complexity, and expected production volume. However, cost-effective solutions can be found without sacrificing quality. Here are ways to manage injection mold costs:

- Material Selection: Choose mold materials strategically. For low-volume production, using aluminum instead of steel can significantly reduce costs.

- Simplify Mold Design: Reducing unnecessary complexity (e.g., undercuts, large features) can decrease manufacturing time and costs.

Mold Materials: Optimizing Durability and Performance

Mold materials greatly influence durability, wear resistance, and total production capacity. They are also a key factor in injection molding costs. Common materials for injection molds include:

- Steel: Steel molds are ideal for long-term, high-volume production. They are durable but generally more expensive than other options. Different steel grades vary in cost and durability:

- P-20: A pre-hardened, high-quality tool steel, suitable for general-purpose molds. It offers moderate hardness, good machinability, polishability, and versatility.

- NAK80: A pre-hardened, high-performance tool steel with excellent wear resistance and dimensional stability. Its higher hardness makes it ideal for high-precision molds and longer production runs.

- 738H: A pre-hardened steel with slightly higher hardness than P-20 but lower than NAK80. It balances machinability and strength, making it suitable for medium to high-volume production.

- Aluminum: Lightweight and easier/faster to machine, aluminum is cost-effective for low-volume production. However, it is less durable than steel and has a shorter lifespan.

- Brass: Known for excellent thermal conductivity, brass is occasionally used in specialized mold applications.

Surface treatments and coatings (e.g., nitriding, physical vapor deposition [PVD]) enhance mold durability and lifespan by improving wear resistance and reducing corrosion. These are important factors influencing injection mold longevity.

Precision Design: Best Practices for Mold Design

Effective mold design is critical to determining the injection process’s production speed, efficiency, quality, and cost-effectiveness. A well-designed tool ensures smooth production and high-quality output. Key best practices include:

CAD and Simulation

Computer-aided design (CAD) software allows designers to visualize the mold, simulate plastic flow, and make adjustments early in the design phase. Simulation helps predict how molten plastic will flow, cool, and solidify, identifying potential issues like air traps, poor flow, or inefficient cooling. Optimizing mold flow via simulation reduces the risk of defects (e.g., warping, sink marks, short shots) before mold manufacturing, saving time and costs associated with rework or production downtime.

Cooling Line Placement

Strategic cooling line placement ensures uniform heat removal from the mold. Uneven cooling can cause warping or deformation, especially in larger or complex parts. Proper cooling line design involves positioning channels throughout the mold to achieve uniform temperature distribution across all part areas. Optimizing the cooling system also shortens cycle times without compromising part quality—faster cooling allows earlier part ejection and faster cycle repetition, boosting production efficiency.

Molding Pressure and Tight Tolerances

Adequate pressure ensures all mold areas are filled, particularly for parts with complex geometries or fine details. However, excessive pressure can cause flash (excess material at edges), while insufficient pressure leads to short shots (incomplete mold filling). Designers must carefully balance injection pressure and tight tolerances to ensure accurate part 成型 without defects. This requires precise control of molding parameters (temperature, pressure, cooling rate) to meet all dimensional and quality requirements.

By focusing on these key practices, designers can create tools that efficiently and cost-effectively produce high-quality parts.

Mold Manufacturing Process: From CAD to Finished Injection Mold

After mold design, the manufacturing process follows these general steps:

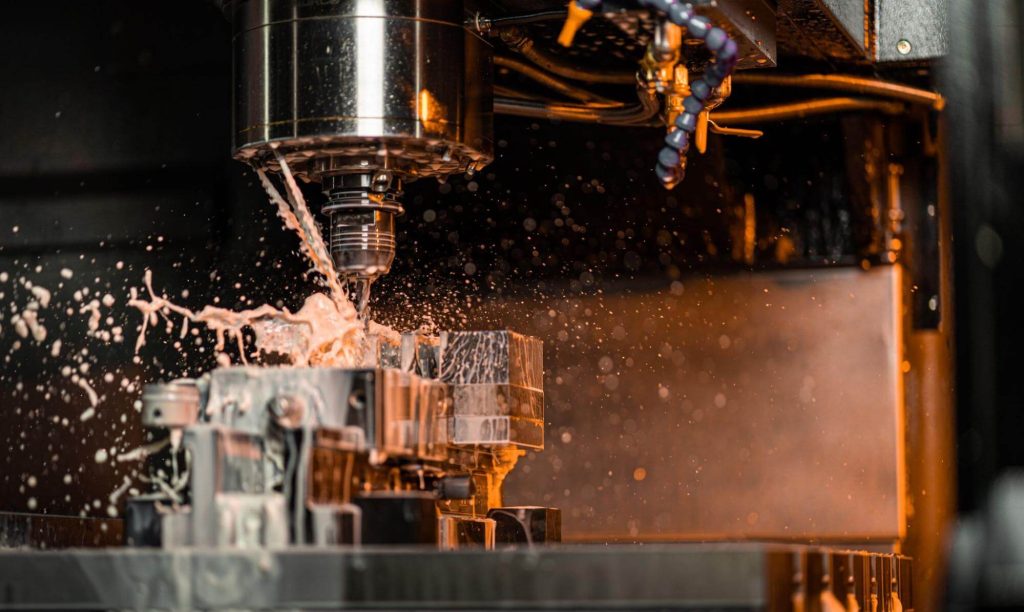

- CNC Machining: Precision machining using 3-, 4-, or 5-axis CNC creates mold cavities, accurately replicating the part design from the CAD model.

- Electrical Discharge Machining (EDM): Performed after traditional machining, EDM creates complex details and features (e.g., engraving, runners, undercuts) or tight tolerances (as low as +0.002 inches) that are difficult to achieve with conventional methods.

- Finishing: After machining, mold surfaces are polished or textured to match the desired final part surface finish.

These steps create a streamlined manufacturing process, ensuring precision and high-quality results.

Injection Mold Validation and Testing

Before mass production, rigorous testing and validation ensure the mold meets specifications. Two key methods for validating injection molds are:

- Design Validation: Before tool manufacturing, computer simulations check for potential design flaws (e.g., air traps, poor flow, inefficient cooling).

- Test Runs: Once manufactured, early production test runs (trial shots) establish optimal injection parameters, identifying and correcting issues related to part defects, mold flow, or cooling.

By validating and testing tools early, manufacturers reduce risks of production delays, costly rework, and defective parts.

Mold Lifespan and Maintenance

Proper maintenance is essential to extending mold lifespan and ensuring consistent production and product quality. Key considerations include:

- Cleaning and Inspection: Regular cleaning prevents plastic buildup in the mold, while inspections identify signs of wear or damage.

- Repairs: Proactive repairs (e.g., re-coating surfaces, replacing worn components like ejector pins, springs, or mold inserts) extend tool life and improve process repeatability.

- Wear Monitoring: Tracking wear over time helps predict maintenance needs, reducing unexpected downtime during long production runs.

Specialized Mold Solutions: Overmolding and Complex Geometries

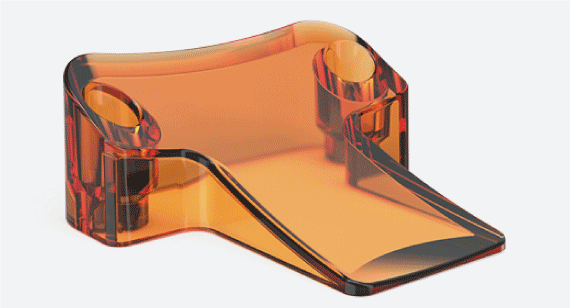

Certain injection molding projects involve complex production requirements, requiring specialized mold solutions. These advanced technologies enable manufacturers to create multi-material parts, integrate components, or achieve complex/hollow geometries:

- Overmolding: Combines two or more materials by injecting one material over or around another. This often adds ergonomic grips, protective layers, or multi-functional elements to a base component, enhancing functionality, durability, and aesthetics.

- Two-Shot Molding: A type of overmolding that combines two materials in a single injection operation. It involves higher upfront mold investment but is more efficient and cost-effective for high-volume production.

- Insert Molding: Integrates non-plastic components (e.g., metal or electronics) into plastic parts during injection molding. Inserts (e.g., metal threads, electrical contacts) are placed in the mold, and molten plastic is injected around them, encapsulating the insert into a single cohesive part. This is used in applications like medical devices, automotive parts, and electronics where metal components need to bond with plastic.

- Three-Plate Molds: Add an extra plate for greater design flexibility and gating options. They are chosen for parts with high aesthetic surfaces, thin walls, or uniform material distribution, as gating flexibility helps achieve even flow and appearance.

- Unscrewing Molds: Contain threaded cores or cavities for parts requiring internal or external threads. The mold features a mechanism to unscrew the part, enabling production of threaded components.

- Gas-Assisted Molding: Uses gas (typically nitrogen) injected during molding to create hollow sections in thick areas. This reduces material usage, lightens parts, and maintains strength.

- Rotational Molding (Rotomolding): Uses centrifugal force to distribute material evenly in the mold, often for large hollow parts. It is an alternative to blow molding for such components.

Specialized mold solutions expand the possibilities for plastic part design, offering opportunities to reduce costs and improve performance in complex assemblies.

Troubleshooting Common Injection Defects with Mold Solutions

Mold design and maintenance significantly impact the occurrence of injection defects. Understanding these defects is key to improving production efficiency and product quality:

- Flash: Excess material on part edges, often caused by misaligned molds, wear, or excessive injection pressure. To reduce flash, ensure precise mold alignment, maintain mold integrity, and control injection parameters.

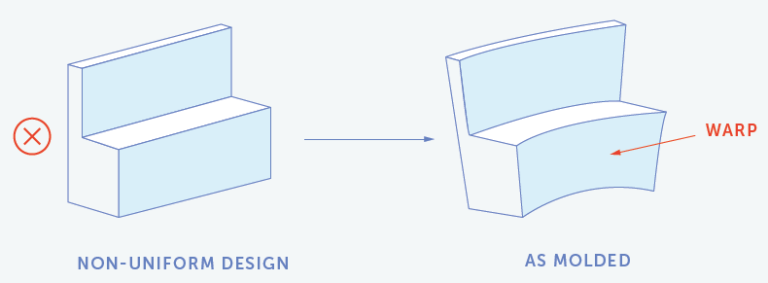

- Warping: Part deformation after cooling, usually due to uneven cooling. Poorly designed cooling channels cause uneven cooling rates, leading to internal stresses. Optimizing cooling line placement and monitoring material properties helps prevent warping.

- Sink Marks: Depressions on part surfaces, typically from insufficient cooling or packing pressure. Avoid sink marks by ensuring adequate cooling time, adjusting injection pressure, and maintaining uniform wall thickness in part design.

- Short Shots: Incomplete mold filling, often due to insufficient injection pressure or material flow. Optimizing injection pressure and improving runner/gate design prevents this defect.

Addressing these defects through tool adjustments and maintenance improves production efficiency and part quality. Regular inspections and proactive design improvements are critical to minimizing issues like flash, warping, sink marks, and short shots.

For more information, contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.