CNC machine safety aims to reduce the risk of accidents and injuries caused by computer numerical control (CNC) equipment such as mills, drills, lathes, and routers. From moving parts, hot surfaces, slippery fluids, and sharp edges to sparks, debris, and noise, CNC machinery can put unprotected workers at risk.

A proper understanding of how to stay safe when interacting with CNC machines is crucial for managing and mitigating these hazards, which can occur during daily operations or due to machine malfunctions. This guide provides tips to help you stay safe in a CNC workshop.

Important: These tips are not intended to be a comprehensive guide or replace existing safety standards. Instead, they serve as a starting point for further exploration of specific frameworks or regulations that may affect your work environment.

Hazard identification and safety compliance are essential, but CNC safety is more than just wearing personal protective equipment (PPE) and following a CNC machine safety checklist. It’s also worth remembering that you can outsource CNC machining to Debaolong Seiko and (safely) get complex parts at an absurdly fast rate.

Understanding Safety Hazards

CNC machining safety hazards can be categorized into four types:

- Mechanical hazards: Moving parts such as spindles, cutting tools, and workpieces can injure an operator’s hands, fingers, wrists, and arms.

- Electrical hazards: The electrical systems that power CNC machinery can expose personnel to electric shock or fire.

- Flying debris: High-speed cutting and machining processes generate flying debris, such as chips, which can cause eye injuries.

- Ergonomic hazards: Prolonged operation, poor posture, or lifting heavy loads can lead to musculoskeletal disorders.

In the United States, the Occupational Safety and Health Administration (OSHA) has issued health and safety regulations for CNC machines in OSHA standard 1910.212(a). As part of a comprehensive safety program, companies should also identify specific hazards in their manufacturing operations and work to mitigate them.

Personal Protective Equipment (PPE)

Workers must wear appropriate personal protective equipment (PPE) when operating or working near CNC machinery. In the United States and Canada, employers are required to provide eye, face, foot, and ear protection. Employees such as CNC operators and machinists are responsible for wearing this equipment.

The following types of personal protective equipment are typically worn to promote CNC machine safety:

- Safety glasses/face shields protect the eyes from flying debris and coolant splatters. They are impact-resistant and include face shields, safety glasses, and safety goggles.

- Cut-resistant gloves protect hands and wrists from cuts, abrasions, and punctures. They can also provide extra grip.

- Hearing protection reduces the intensity of sound reaching the eardrum, helping to prevent noise-induced hearing loss. Earplugs and earmuffs are commonly used noise reduction measures.

- Protective clothing includes aprons and footwear. Examples are flame-resistant fabrics, steel-toe boots, and S3 safety shoes.

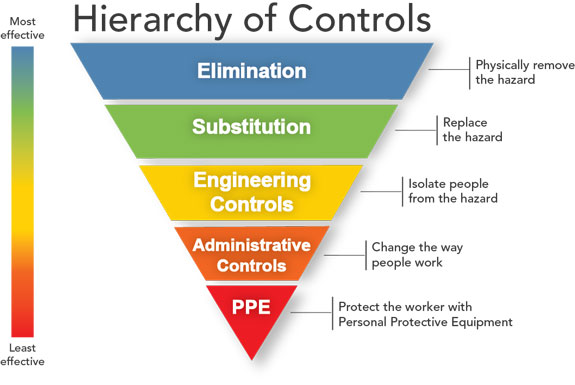

The National Institute for Occupational Safety and Health (NIOSH), a U.S. federal agency that makes recommendations for the prevention of work-related injuries, places personal protective equipment at the bottom of the hierarchy of controls designed to protect workers from harm.

This means that while personal protective equipment is necessary, it is the last line of defense in CNC machine safety. Higher-level controls can more effectively reduce injuries during CNC machining.

Machine Guards for Accident Prevention

Machine guards are safety barriers or devices that enclose hazardous parts of equipment. These protective measures are classified as engineering controls, and machine guards are designed to prevent employees from intentionally or accidentally coming into contact with these parts while the machine is running.

OSHA has issued specific machine guarding standards, including 1910.212(a)(3)(iv) for milling machines. Machine guards can be installed at the factory or added to the machine after it arrives at the CNC machine shop.

Machine guards are mainly divided into three types: fixed, interlocked, and adjustable.

- Fixed guards are attached to the machine and cannot be adjusted by employees while the CNC machine is running. Examples include enclosures, gates, and cutting tool protection covers.

- Interlocked guards, also known as safety interlocks, are movable and combine a physical barrier with a safety mechanism such as a switch. They stop the machine when the guard is opened.

- Adjustable guards can be repositioned or resized according to the size and thickness of the machining operation or workpiece. They require the most operator involvement between runs.

Guards are standard CNC machine safety features, but other precautions are also used. Examples include light curtains, safety contact pads, and CNC machine safety glass:

- Light curtains use infrared beams and self-monitoring circuits to send an automatic stop signal to the CNC machine if the beam is broken.

- Safety contact pads send a stop signal to the equipment when stepped on. Typically, these dedicated foot pads have anti-slip features.

- CNC machine safety glass is impact-resistant, heat-resistant, and coolant-resistant.

Emergency Stop Switches and Lockout/Tagout (LOTO)

CNC machines are also equipped with emergency stop switches that quickly shut down the machine when pressed. These switches, called e-stops, remain in the off position until manually reset. Usually, the e-stop has a large red button that is easy to identify and press during an emergency stop.

Operators must also recognize the locks and tags used in lockout/tagout procedures. These physical locks and warning tags are designed to de-energize equipment and prevent accidental startup, usually during maintenance or repair. CNC operators should not attempt to remove locks and tags, which are intended to protect them from the release of hazardous energy.

CNC machine shops are responsible for training all personnel who will use CNC machines or perform work in any area near CNC machines on lockout/tagout procedures.

CNC Machine Safety Rules

Safe operating procedures help minimize the risk of injury when running CNC equipment. Use the bullet list below as a basic checklist, but consult your company’s CNC machine safety guidelines as they may vary.

- Pre-operation safety checks: Before starting the CNC machine, check it for damage or wear. Tools, fixtures, fluid lines, and guards should be inspected. Ensure all machine guards are in place and verify that all safety devices are working properly.

- Proper workpiece clamping: Secure the workpiece correctly to prevent it from shifting during machining. Unnecessary movement can cause tool breakage or workpiece ejection.

- Tool selection and maintenance: Use the correct CNC tools for the job and regularly inspect and maintain tools to ensure they are sharp and undamaged. If you don’t perform maintenance yourself, ensure all preventive maintenance is up to date.

- Safe machine operation: Never bypass safety interlocks or operate the machine with guards removed. Always stay alert and focused while the machine is running.

- Check yourself: Are you wearing the correct personal protective equipment? Is your clothing going to get caught in the machine or guards? Is long hair tied back?

Handling CNC Machine Malfunctions

CNC machines are reliable, but unexpected malfunctions can occur. Programming errors, improper tools, excessive vibration, or lack of daily maintenance are several causes. When it comes to machine safety in the event of a CNC malfunction, keep these tips in mind.

- Don’t panic: Stop the machine immediately using the emergency stop button.

- Assess the situation: Determine the cause of the malfunction, such as equipment jamming, and whether it poses an immediate danger.

- Report and repair: Report the malfunction to the appropriate personnel, who must follow lockout/tagout procedures before attempting any repairs.

Safety Training Programs and Safety Culture

Training is crucial for creating and maintaining a safe work environment. Any employee operating a CNC machine needs operator training on specific equipment and knowledge of the company’s emergency response plan. Regular safety audits can identify potential hazards and ensure compliance with CNC machine safety protocols.

Continuous improvement, the process of making incremental changes over time, can help you build a safety culture characterized by proactive identification and mitigation of risks. A safety management system can also help you implement policies and procedures that everyone needs to follow.

“We find that people struggle to enforce their policies and procedures. What’s needed is a safety management system, which is a proactive process that builds an established safety culture.” – Jim Testo of EHS Risk Management in “Rust, Paint, and Why You Need a Safety Culture”.

Other CNC Machine Safety Precautions

CNC machine safety also includes safety signage, machine maintenance, electrical safety, and environmental considerations.

Safety Signage

There are several different types of safety signs for CNC machines.

- Danger signs are used in areas with immediate hazards that could result in severe injury or death if precautions are not taken.

- Machine warning signs may include warnings to wear protective equipment or be cautious when using the equipment.

- Moving machinery signs remind workers of specific risks posed by moving parts, such as to fingers and hands.

CNC Machine Maintenance

Well-maintained CNC machinery is less likely to malfunction and cause injuries. Maintenance is usually required daily, regularly, and annually. This is based on machine utilization and the manufacturer’s specifications for the CNC machine you are using.

It’s always a good idea to check the machine’s operating manual, but here are some tips for starting a preventive maintenance program for your CNC machine:

- Daily tasks include checking lubrication levels, emptying chip hoppers, inspecting all safety mechanisms, ensuring the equipment is free of damage, and wiping surfaces to prevent metal chip accumulation.

- Regular tasks range from cleaning debris from coolant tanks to disassembling chucks and jaws for cleaning. Coolant or lubricant may need to be cleaned or replaced. Typically, these tasks are performed every six months or 1,000 hours.

- Annual tasks include running software simulations to check tool alignment and indentations. Software updates may also be included.

Electrical Safety

Improper grounding, incorrect wiring, and power surges can cause electric shock, burns, fires, or fatal electrocution. To mitigate these risks, manufacturers and machine shops need to conduct regular inspections and retain the services of trained electricians. Always follow lockout/tagout procedures before inspecting and repairing equipment.

Environmental Considerations

CNC machine safety can raise environmental considerations beyond the use of the equipment. For example:

- Proper ventilation can reduce employee exposure to fumes, dust, and coolant mist.

- Adequate lighting can promote safe machine operation and reduce the risk of errors.

- Housekeeping is crucial because debris or obstacles around CNC machines can create tripping or slipping hazards.

In addition, when disposing of or cleaning up chemicals such as machine coolants and lubricants, you should always check the Safety Data Sheet (SDS) or Technical Data Sheet (TDS) for proper procedures.

Trends in CNC Machine Safety

Advances in technology, safety standards, and industry best practices are improving safety for CNC operators and machinists.

- Enhanced protection systems, such as automatic doors and interlocked barriers, can prevent access to hazardous areas while the CNC machine is running.

- Programmable Logic Controllers (PLCs) can be integrated into CNC machines to monitor and control safety functions. They can also shut down equipment quickly.

- Safety sensors and laser scanners can detect the presence of CNC operators near hazardous areas and slow down or stop the machine.

- Artificial Intelligence (AI) and the Internet of Things (IoT) can monitor CNC machine conditions in real-time and recommend predictive maintenance to help prevent safety issues.

- Virtual Reality (VR) and Augmented Reality (AR) simulations allow workers to experience safety procedures firsthand.

ISO 12100 outlines requirements for the design of mechanical safety systems. Although ISO 12100 itself does not contain CNC safety standards, it includes general principles for risk reduction.

Choosing Debaolong Seiko for CNC Machining Services

CNC machining can speed up production, improve precision, and reduce manufacturing costs. Due to automation, CNC machines can also reduce operator fatigue and the risk of injuries and errors. However, risks exist, and using personal protective equipment alone is not sufficient. Machine guards, emergency stops, and LOTO procedures are all part of the solution.

Debaolong Seiko offers CNC machining services and works with a network of carefully vetted CNC machine shops to ensure we can provide you with the parts you need, manufactured to your specifications, in as fast as one day.

For more information, please contact us at Debaolong Seiko. You are also welcome to upload your design to Debaolong Seiko for a quote.