Whether you want to print it, animate it, or render it: if you want to represent an object in three-dimensional space, you need a 3D file. These files are essentially large lists of coordinate points that define a shape. However, designing a 3D object by declaring coordinates manually would be extremely difficult for humans.

Instead of theoretically writing these coordinate lists by hand, you can use 3D modeling programs to create 3D objects through a visual interface. Computer-Aided Design (CAD) software handles all the calculations and creates files containing all the coordinates, so designers only need to focus on shape and size.

However, not all CAD programs are the same; they are usually built around specific 3D modeling methods.

In this article, we will explore the four main types of 3D modeling, their pros and cons, and some programs that use them.

Which Modeling Technique Will You Choose?

Contemporary 3D modeling revolves around four main methods, each with its own advantages and disadvantages. Most other types of 3D modeling you will encounter are either subsets of these four main types or highly specialized for very specific goals.

- Solid Modeling: Deals with 3D shapes like cubes, cylinders, and spheres. Shapes may vary, but they work together like building blocks. Depending on the input, some shapes add material, while others remove it. Some programs allow modifiers to manipulate these solids as if you were physically milling them in a workshop. Solid modeling is relatively straightforward for both users and computer performance.

- Wireframe Modeling: Useful for surfaces that are complex and curved. If you find the basic building blocks of solid modeling too rigid for certain applications, wireframe modeling offers precision for more intricate forms. However, increased complexity brings drawbacks, such as the need for advanced design skills and higher computational demands.

- Surface Modeling: Allows users to create smooth surfaces that seamlessly integrate into watertight or manifold 3D objects. This can be handled by advanced programs that require more work and computing power. That said, here you can achieve shapes nearly impossible with the first two methods.

- Digital Sculpting: Starts with a shape made of “digital clay,” which can be manipulated “by hand” using different tools. It offers a very different modeling experience and is arguably used for more artistic purposes.

Now that we have a rough idea of what we’re discussing, let’s look at each 3D modeling type in more detail.

1. Solid Modeling

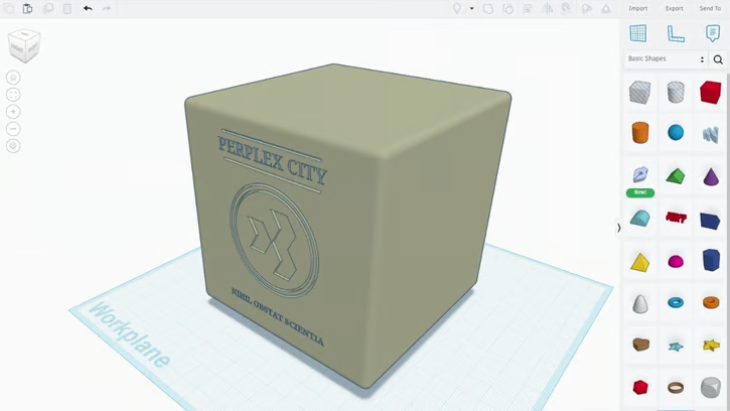

Solid modeling involves using basic objects to build more complex shapes. Some programs let you start with cubes, cylinders, spheres, and prisms, while others allow you to draw 2D sketches and extrude them into 3D parts. These parts can then be combined or “sculpted” using boolean operations to get closer to the final design.

This modeling style is useful for Computer-Aided Design (CAD). It is an industrial 3D modeling type where precise dimensions (width, length, radius) and features like extrusions, fillets, and chamfers are crucial for creating 3D objects manufacturable via 3D printing, CNC milling, or other industrial processes.

Popular solid modeling programs include entry-level tools like Tinkercad and SolveSpace, and more advanced options like Autodesk Fusion or Shapr3D.

Advantages

- Entry-level solid modeling programs are easy to understand and get started with, requiring little training.

- Solid modeling requires relatively low computational power, so you don’t need a very powerful computer initially.

- In theory, the finished model should be manufacturable in the real world.

Disadvantages

- Representing organic shapes is nearly impossible or requires a lot of tedious work.

2. Wireframe Modeling

When we observe the real world, we quickly realize that things are not just a bunch of perfect cubes and spheres. To create models of objects that look more realistic and less like they just came out of a factory, another modeling technique is needed.

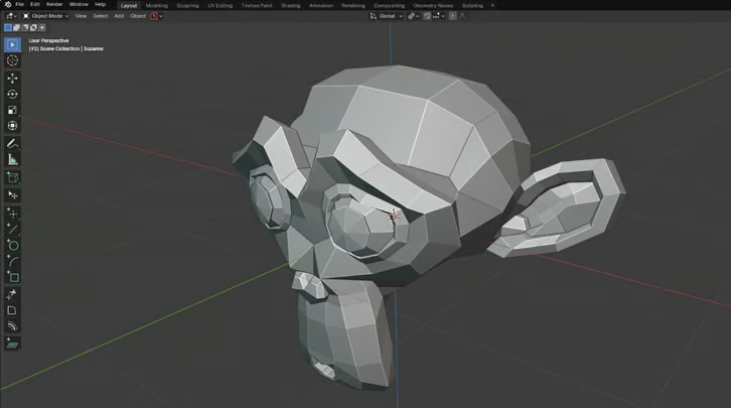

Wireframe modeling builds shapes through a network of points called vertices. Each set of at least three vertices can connect to form a face, and each vertex can be part of one or more faces. The size and shape of the object and its components are defined by the position of each vertex.

Many wireframe modeling tools use triangles as the basic element; the more triangles in a model, the greater control we have over it, and the more realistic it can be. Polygon count (the total number of triangles and other flat shapes in the model) is usually a good indicator of a model’s complexity.

Numerous programs use this method; some popular ones include Blender, Maya, and Daz 3D.

Advantages

- By controlling the core elements (vertices), you have greater control over the 3D object’s components.

- You can add details to make the model more realistic—details that would be very difficult or impossible with solid modeling tools.

Disadvantages

- While surface modeling lets you control more complex shapes, it has a steeper learning curve than solid modeling.

- As the number of triangles and polygons in the model increases, you’ll need a more powerful computer for rendering and texturing.

3. Surface (Curve) Modeling

Surface modeling relies on guide curves and surfaces to define a part’s shape and curvature. The software then calculates smooth surfaces that connect these guide curves. Think of it like building an airplane or ship: the surfaces created are their hulls.

In fact, airplanes and ships are why surface modeling was invented. In aerodynamic and thermodynamic design, the flow of fluids around a shape determines the design’s success. Thanks to guide curves, control points, and control surfaces, surface modeling is the best way to tackle these challenges.

Note that because this modeling type focuses on surfaces, it may create models that look great but are unmanufacturable due to limitations in our processes or materials. If you want to create a physical representation of the model, you need to check if all surfaces are connected and if there are conflicts between parts—in short, whether it is manifold.

No program is exclusively dedicated to this technique; it is just another tool in their toolkits. However, its fundamental principles are so unique that it is considered a distinct modeling technique. In many programs, the primary tool for this work is called “Loft.” Some programs that handle this modeling type include Catia, FreeCAD, Inventor, and SolidWorks.

Advantages

- You can create smooth surfaces in ways that solid and wireframe modeling cannot.

- Flowing shapes and curves are easier and faster to create than with any other 3D modeling type.

Disadvantages

- Your design may be difficult or impossible to manufacture; its feasibility depends entirely on your understanding of modeling, surface flow, and manufacturing.

4. Digital Sculpting

Finally, let’s dive into digital sculpting. The modeling techniques we’ve seen so far involve precisely manipulating 3D objects. At the other end of the spectrum is digital sculpting, where 3D models start from a basic shape and can be stretched, added to, or carved like digital clay. In many ways, digital sculpting aims to bring the experience of physical sculpture to digital creation tools.

Shapes and effects that are difficult or impossible with other modeling techniques are easy with digital sculpting. Specifically, organic shapes, natural objects and textures, clothing, etc.—it all depends on your skill in creating and interpreting them, and perhaps some additional equipment. A stylus and graphics tablet (or touchscreen) and a powerful computer are likely necessary for this type of modeling. While conserving polygon count is key for other techniques, models created with digital sculpting can easily become excessively complex if not managed.

Popular software for this modeling type includes Blender (the Swiss Army knife of modeling), Cinema 4D, and the relatively new Nomad Sculpt.

Advantages

- Shapes that were previously impossible to make—characters, animals, plants, clothing, almost anything—can be sculpted from digital clay.

- Compared to other techniques, digital sculpting is more open to experimentation and arguably more intuitive (if you have crafting skills).

Disadvantages

- Digital sculpting relies almost entirely on fine control of “digital clay”; you need a stylus and touchscreen to make the most of it, and these devices can be expensive depending on the quality desired.

For more information, please contact Debaolong Seiko. You are also welcome to upload your designs to Debaolong Seiko for a quote.