All 3D printing Materials

We offer a wide variety of 3D printing plastic materials, ranging from thermoplastics for functional parts to highly detailed resins (thermosetting plastics) for visual prototypes.

- All uploads are secure and confidential

Plastic 3D printing

Name

Description

Price

Alloy Steel

High rigidity, excellent details, affordable price.

ABS

General-purpose plastics have improved mechanical and thermal properties compared to PLA.

Nylon

Used as a replacement for functional injection molded parts, with excellent chemical resistance.

Resin

High detail and smooth surface, similar to injection molded prototypes.

PETG

Suitable for mechanical parts with high impact resistance and flexibility. Sterilizable.

TPU

Rubber-like material, suitable for pipes, handles, seals, and gaskets.

ASA

Used as a substitute for functional injection molded parts, it has excellent chemical resistance.

PEI

Engineering plastics, high-performance applications, flame retardant.

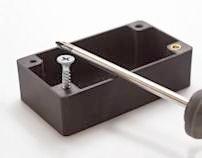

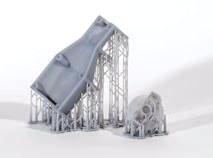

3D-printed plastic parts

Additive Manufacturing (AM) is an excellent choice for quickly and cost-effectively producing plastic components. Compared to subtractive manufacturing, plastic AM typically offers lower costs, and its speed and automation capabilities enable rapid, iterative component optimization. 3D printing plastic parts differs from subtractive CNC plastic machining by precisely building components layer by layer. Due to the wide range of polymer materials available for 3D printing, it is well-suited for various applications, including prototyping and low-volume production.

Plastic 3D Printing Services

DeBaoLong seiko offers advanced plastic prototyping services, ensuring consistent quality and fast turnaround times. With our global network and diverse capabilities, we can manufacture parts using various materials and performance characteristics through multiple production methods. We specialize in industry-standard 3D printing processes, including FDM, SLA, SLS, and MJF, providing comprehensive support for your custom 3D printing projects, from rapid prototyping to industrial applications. Contact us today to get started with our plastic 3D printing solutions.

Custom Plastic 3D Printing

Our services enable designers and engineers to create custom 3D-printed plastic parts for a wide range of applications across industries such as aerospace, automotive, defense, industrial automation, machinery, manufacturing, medical devices, hardware setup, energy, and robotics. We offer a variety of plastic materials and technologies suitable for producing plastic parts, including post-processing options for certain plastic 3D printing methods.

Frequently asked questions

What type of plastic is used in 3D printing?

We offer 3D printing services for the following plastics: PLA, Formlabs resin, 3D Systems resin, ABS, nylon, PETG, TPU, ASA, and PEI.

How strong is 3D-printed plastic?

Due to the wide variety of polymers available, the strength of 3D-printed plastic parts often varies. This also depends on the printing orientation and technology. We recommend using Markforged Onyx, PA12, PETG, and PP for optimal part strength.

How accurate is plastic 3D printing?

The accuracy of plastic 3D printing varies depending on the printing technology used. FDM technology typically achieves an accuracy of approximately 0.1 millimeters, but layer lines may appear. SLA technology offers higher accuracy, approximately 0.05 millimeters, and a smoother surface. SLS technology is comparable to SLA in terms of accuracy, but the surface texture of the printed parts is rougher. In addition, factors such as material type, layer height, and post-processing techniques also affect printing accuracy.