All CNC machining meterials

We offer CNC machining services for a variety of metal and plastic materials, suitable for multiple industries. Whether you need single-piece prototypes or custom parts for final use, we can meet your needs.

- All uploads are secure and confidential

Metal CNC Machining

Name

Description

Price

Aluminum

High processing performance and ductility, excellent strength-to-weight ratio.

Browse Aluminum materials

Stainless steel

High strength, corrosion resistance, high temperature resistance.

Browse Stainless steel materials

Mild steel

High machinability and ductility, good strength-to-weight ratio.

Browse Mild steel materials

Brass

Low friction, excellent electrical conductivity, golden yellow appearance.

Browse Brass materials

Copper

Excellent thermal conductivity and electrical conductivity.

Browse Copper materials

Alloy Steel

High strength and toughness, fatigue resistant.

Browse Alloy steel materials

Tool steel

High hardness and rigidity, wear-resistant.

Browse Tool steel materials

Titanium

Excellent strength-to-weight ratio, widely used in aerospace, automotive, and medical industries.

Browse Titanium materials

Inconel

High-strength and corrosion-resistant nickel alloy.

Browse Inconel materials

Invar 36

Nickel alloy with extremely low thermal expansion coefficient.

Browse Invar 36 materials

Plastic CNC Machining

Name

Description

Price

POM (Delrin/Acetal)

High rigidity, high precision, low friction, easy to process.

Browse POM (Delrin/Acetal) materials

Nylon

Excellent mechanical properties, heat resistance, chemical corrosion resistance, and wear resistance.

Browse Nylon materials

ABS

Common thermoplastic materials with good impact resistance and easy to process.

Browse ABS materials

PEEK

High-performance thermoplastic material with extremely high strength and excellent heat and chemical resistance.

Browse PEEK materials

PTFE (Teflon)

Low friction, chemical corrosion resistance, and high temperature resistance.

Browse PTFE (Teflon) materials

Polycarbonate

High toughness, excellent impact strength, transparent.

Browse Polycarbonate materials

Polyethylene

Excellent strength-to-weight ratio, impact resistance, and weather resistance.

Browse Polyethylene materials

PVC

Excellent chemical and weather resistance and good toughness.

Browse PVC materials

PMMA (Acrylic)

Transparent rigid plastic often used as a substitute for glass.

Browse PMMA (Acrylic) materials

PET

A tough plastic with excellent wear resistance and mechanical strength.

Browse PET materials

Polypropylene

Excellent chemical resistance. Food grade products available.

Browse Polypropylene materials

G-10

High strength, low water absorption, excellent electrical insulation properties, and chemical resistance.

Browse G-10 materials

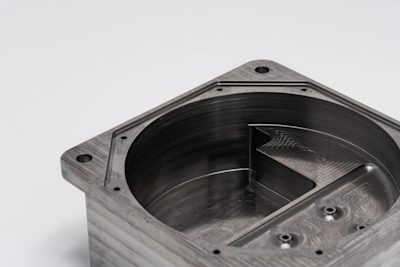

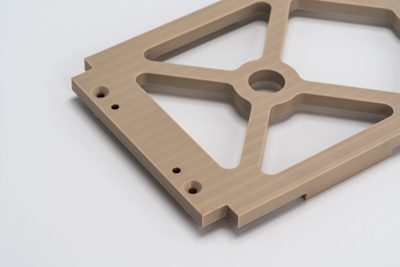

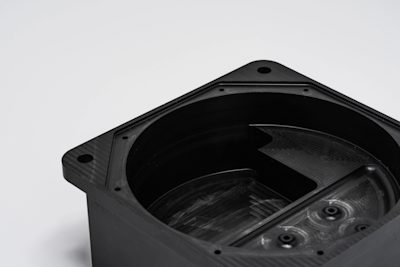

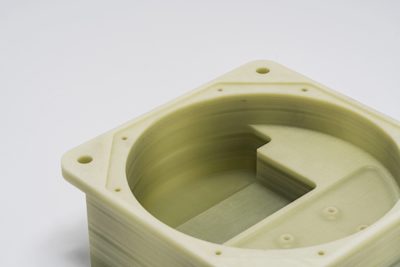

Metal Processing

Metal processing refers to the process of cutting raw metal materials to create the desired shapes or objects. This process is most accurately performed using CNC (Computer Numerical Control) machines, which can process nearly any three-dimensional model designed using CAD (Computer-Aided Design) software. Our processing network primarily utilizes 3-axis and 5-axis CNC machines to produce various metal parts that have been inspected by Debaolong Seiko. The advanced CNC metalworking machines we use can process complex features on parts with extremely high precision while strictly controlling tolerances.

Metal Milling

CNC metal milling machines remove portions of metal from metal billets or metal sheets by installing high-precision cutting tools on a high-speed rotating spindle. The cutting tools can be replaced with different specifications of tools depending on the material thickness or design complexity. Raw metal materials are secured to a rotatable workbench to allow the tool to access multiple angles. For complex designs requiring machining from a single piece of metal, CNC metal machining using a milling machine is the optimal choice.

CNC Metal Machining

This CNC metal machining process is highly suitable for shaping parts that can be machined from a single piece of metal, much like carving a surfboard from wood, but using metal, drills, and a computer.

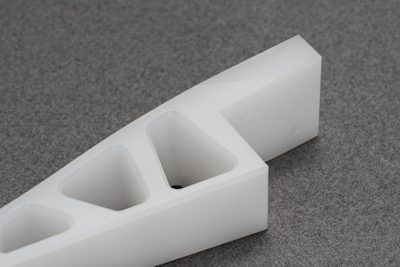

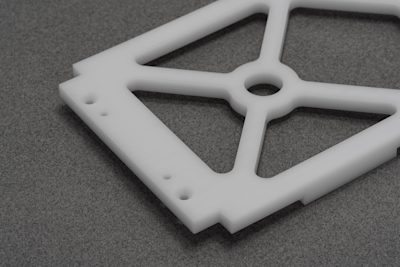

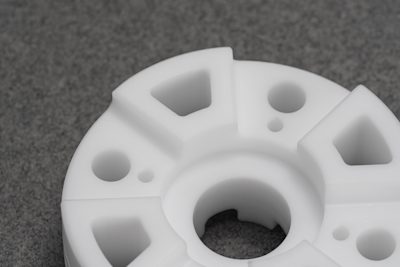

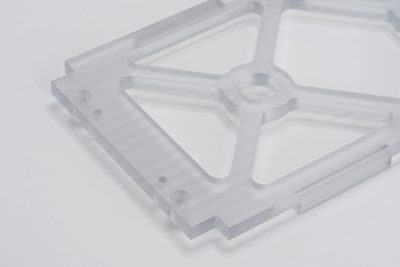

Plastic Processing

Plastic parts are an ideal alternative to metal parts due to their lightweight, ease of processing, and typically lower cost. Due to their compatibility with a wide range of plastic materials, CNC machining remains the preferred option for engineers and product teams when producing plastic parts. Different types of plastics have their own advantages and disadvantages in CNC machining applications. Please refer to the list of available materials above.

CNC Plastic Machining

Plastic CNC machining is a viable subtractive manufacturing process for producing complex plastic components. Advanced 3-axis, 4-axis, and 5-axis CNC machines can produce high-quality final parts with complex geometries. Compared to 3D printing or injection molding, CNC machining of plastics offers advantages in terms of tighter tolerance requirements and a wider range of available polymer materials. For small-batch production, plastic CNC machining is more cost-effective than injection molding.

Frequently asked questions

What is the cost of metal CNC machining?

The cost of metal CNC machining depends on the complexity and size of the parts, as well as the type of metal used. These factors will influence the type of machine tool required, the production time for the parts, and the cost of raw materials.

What is metal machining?

Metalworking is a manufacturing process that involves cutting metal blanks until the desired shape or object is obtained. In CNC metalworking, computer numerical control (CNC) milling or turning tools are used to remove excess material from metal blanks with extreme precision, enabling the production of complex parts with dimensional accuracy.

What can metal CNC machine tools process?

With CNC machine tools, you can manufacture almost any part that can be represented in a 3D CAD file. The more complex the machine tool (e.g., 5-axis CNC milling machine), the more complex the geometry that can be machined.

What are processable plastics?

Plastic processing is a manufacturing process that uses computer numerical control (CNC) milling tools to gradually remove unwanted geometric shapes from plastic blanks, producing complex parts with extremely high precision.

Which plastic is best suited for processing?

ABS is an excellent general-purpose plastic suitable for CNC machining, thanks to its good machinability and dimensional stability. For applications requiring low friction and high rigidity, POM is a viable option. For applications with special requirements (such as specific mechanical properties or aesthetic characteristics), other plastics may also be good choices.