Online injection molding service

- Access a wide range of custom services from Debaolong injection molding service. Prototype and production tooling. Upload your parts for a free quote and expert feedback.

Our custom injection molding services

Create parts of all complexities sized from 3 mm (0.12 in) to 2 m (79 in) with Debaolong Seiko. Lead times are as fast as 10 days,depending on part size, complexity, and volume. Tighter tolerances are available on request.

Liquid silicone rubber molding

A thermoset process that involves mixing a two-part solution together to produce flexible and durable parts.

Overmolding

A manufacturing process in which one plastic material is molded over another to create a single component.

Insert molding

A manufacturing process in which a part is molded around a pre-installed insert in the tooling.

Plastic injection molding

Injection molding is the manufacturing process of injecting high-pressure thermoplastic into a mold. Ideal for high-volume production.

Gallery of plastic injection molded products

Equipment Box

Industry: Agriculture Material: Polypropylene (PP) Surface Treatment: D2

Climate detection component

Industry: Indoor climate technology Material: ABS Surface treatment: As per processing status

New Energy Electrical Box

Industry: Electric Vehicle Charging Material: PC + ABS Surface Treatment: VDI33

Quotation options

Diversified quotes, customers can upload drawings of parts that need to be customized.

- Customers can send drawings to Debaoloong@gmail.com or register on the website and upload your files.

- CAD drawings include (STEP, STP, IGES, IGS, SLDPRT, 3DM, PDF, SAT, or X_T)

- Please specify your requirements (material, quantity, delivery time)

- We will provide a quotation as soon as we receive your inquiry. The quotation will be sent to the email address you provided. Please check your email promptly.

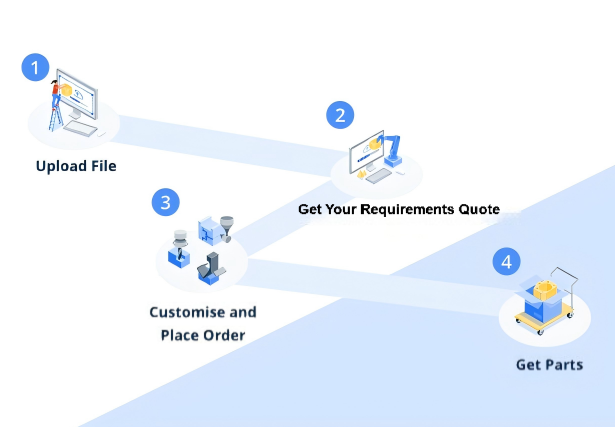

Our ordering process

Debaolong Standard - consistent quality, every time

Debaolong Seiko takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets Debaolong Standard.

Inspection standards

Visual and dimensional inspection & defects

Dimensional accuracy

Sample measurements & general rules

Cosmetic standards

Standard offering & post-processing options

Specialist industries

We’ve manufactured millions of parts for all sorts of applications, but we’re especially knowledgeable in these areas.

Robotics & automation

Automotive

Industrial machinery

Aerospace & aviation

Our client network

Debaolong Seiko is dedicated to providing one-stop custom manufacturing services, including CNC machining, 3D printing, sheet metal fabrication, injection moulding, die casting, and mould making. Our services are widely recognised and trusted worldwide, with clients in Europe, the United States, Russia, Japan, and South Korea.

Advantages of injection molding with Debaolong

1.A wide range of materials

Injection molding offers great flexibility in material selection. Depending on the mechanical properties your part requires, you can use molded parts to achieve impact resistance, chemical resistance, rubber-like elasticity and dimensional stability. We can source thousands of custom materials on demand and advise you on the best options for your project while minimizing your costs.

2.Single-cavity, multi-cavity and series molds

Whatever the size of your injection molding project, we can help you design and build the ideal mold for cost-effective production. In addition to single-cavity molds, we offer advice on multi-cavity molds that can produce several identical models simultaneously, reducing your cost per part and speeding up production.

3.High quality standards

The injection molding process produces precision parts with high levels of accuracy and consistency, and our comprehensive quality management process ensures that your molded parts always meet specifications.

More resources for injection molding

How much does plastic injection molding cost?

There are many factors that determine the cost of injection molding your custom parts. The three main expenses are tooling, materials and production.

Who owns the injection mold?

Customers retain ownership of all custom tooling they develop, however, any reusable proprietary components developed by the manufacturing partner (MP) will become the MP’s property. All custom tooling will remain at the MP’s facility for a minimum of two years unless otherwise agreed. If the tooling is inactive after two years, the MP may contact Debaolong Seiko to determine if the tool must be retained for additional time. Debaolong Seiko will then contact the customer to make further arrangements. Molds can be transferred to any desired location upon request and at the requester’s expense.